100kN UTM - Universal Testing Machine TTM-100

100kN UTM - Universal Testing Machine TTM-100 is designed for precise static property testing, including tensile, compression, bending, shearing, peeling, tearing, loading, relaxation, and reciprocating tests on metal, non-metal, and composite materials.

It automatically calculates key testing parameters such as ReH, ReL, Rp0.2, Fm, Rt0.5 , Rt0.6, Rt0.65, Rt0.7, Rm, E . The machine conducts tests and generates data in compliance with ISO, ASTM, and DIN standards.

- Calibration of load measurement instruments for uniaxial testing machines

- Verification and calibration of force-measuring systems in tension/compression machines

- Tensile testing of metallic materials at room temperature

- Mechanical properties of carbon and alloy steel fasteners

- Bend testing of metallic materials

- Steel for reinforced concrete – Ribbed bars

- Tension testing of metallic materials

- Mechanical testing of steel products

- Compression testing of metallic materials at room temperature

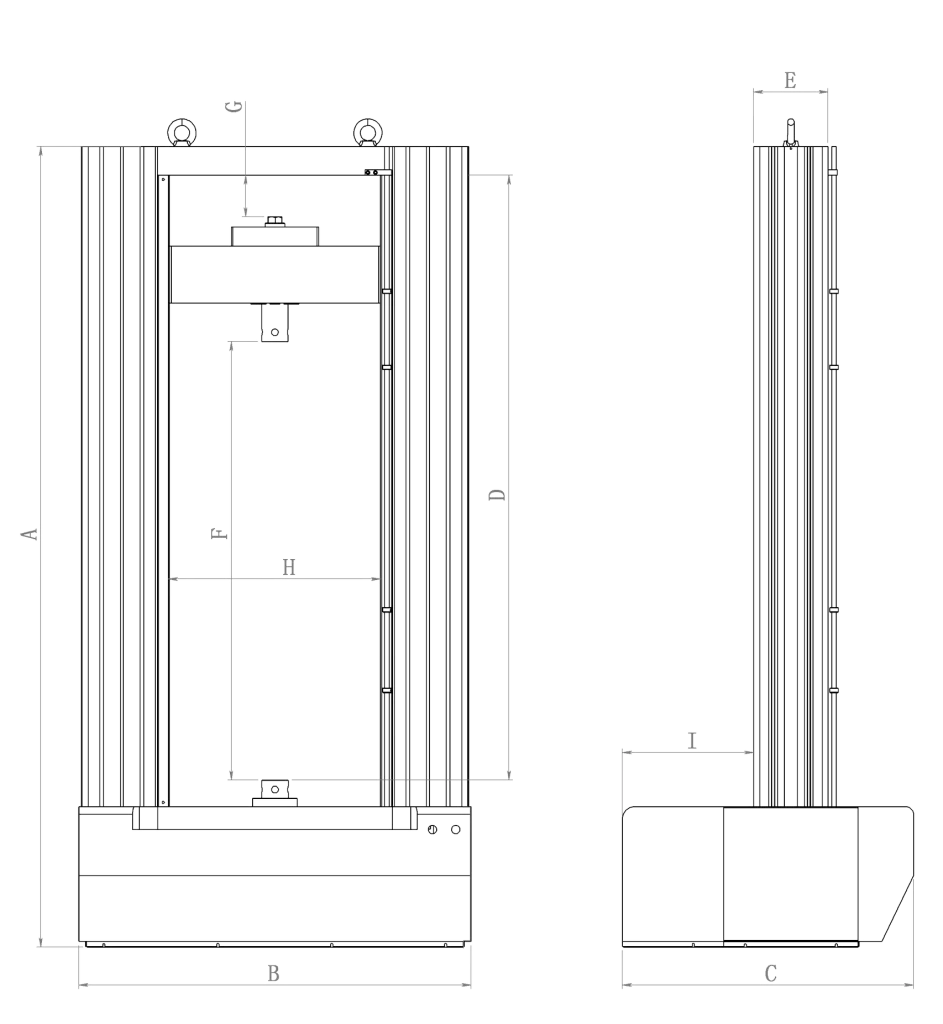

Mechanical Framework and Design

The main frame has a durable door-frame structure, comprising a base, two fixed beam, one movable crosshead, four columns, and two screws.

The transmission loading system features an AC servo motor with a synchronous cog belt speed reducer, driving a high-precision ball screw to control crosshead movement with accuracy.

Engineered for performance and efficiency, it offers:

- A sleek, modern design

- Outstanding stability and rigidity

- Precise control

- Smooth, efficient operation

- Low noise performance

- Energy-saving, eco-friendly functionality

| Mark | A | B | C | D | E | F | G | H | I |

|---|---|---|---|---|---|---|---|---|---|

| Value (mm) | 2100 | 1033 | 770 | 1593 | 196 | 1150 | 110 | 600 | 346 |

Control and Measurement System

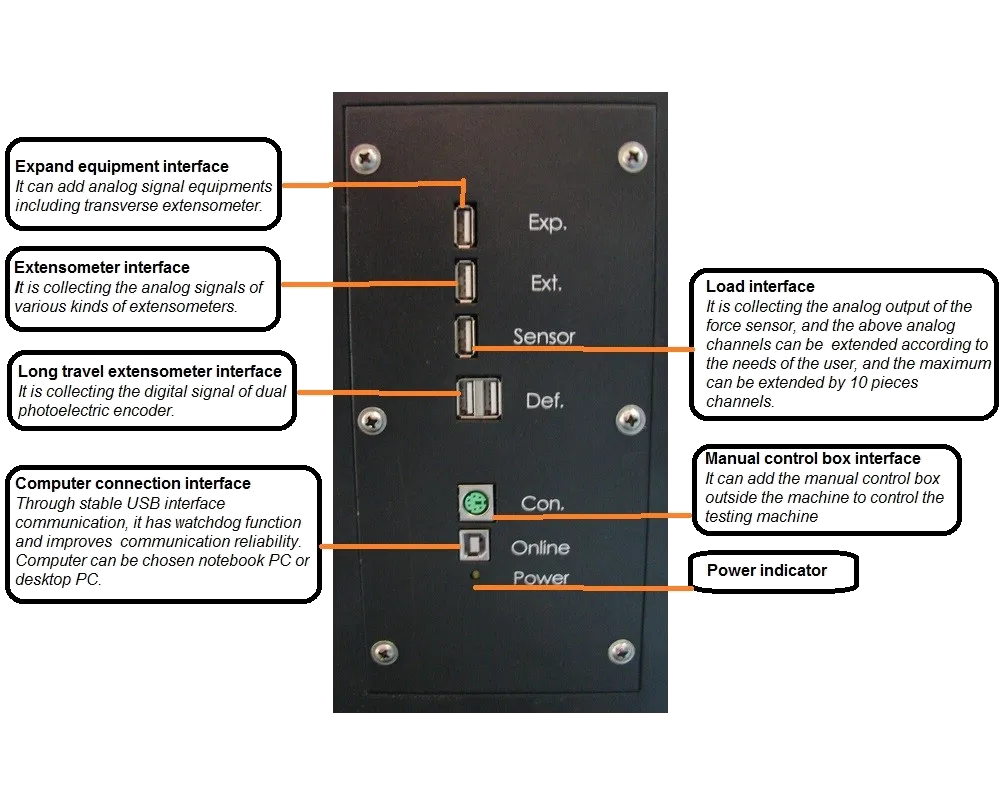

This machine is equipped with the advanced DSC-10TT full-digital closed-loop control system for precise measurement and control. A computer oversees the testing process, providing real-time curve visualization and data processing.

After testing, the curve can be enlarged for detailed reanalysis and data editing using the built-in graphical processing module. With its cutting-edge technology, this machine meets international performance standards.

-

Advanced Control Flexibility – Supports special displacement, deformation, and speed closed-loop control. The testing speed and method can be adjusted in real time, allowing for greater flexibility and customization.

-

Comprehensive Safety Protections – Multi-layer protection system includes software and hardware safeguards, preventing overloading, over-current, overpressure, under-voltage, overspeed, and other potential risks.

-

High-Resolution Data Processing – Equipped with three high-speed 24-bit A/D switching channels, achieving an effective resolution of ±1/300,000. Maintains consistent resolution throughout the entire testing process.

-

Stable & Reliable Data Transmission – Utilizes USB or serial communication, ensuring steady data transfer with strong anti-interference capabilities.

-

Enhanced Signal Capture – Features three pulse signal capture channels (one for displacement and two for deformation) with advanced quadruple frequency technology, increasing effective pulse quantity fourfold. The maximum capture frequency reaches 5MHz for superior accuracy.

-

Precision Motor Control – Incorporates a servo motor digital-driven signal with a PWM output frequency range from 0.01Hz to 5MHz, ensuring precise motion control.

Key Benefits of the Control and Measurement System

1. DSC-10TT Full Digital Closed-Loop Control System

The DSC-10TT is our latest-generation specialized control system for testing machines. It incorporates advanced servo motor control chips and a multi-channel data acquisition and processing module, ensuring high-speed, precise control and consistent sampling. Designed with a hardware-based architecture, it enhances system stability and reliability.

2. High-Efficiency & Professional Control Platform

The DSC-TT system integrates DSP (Digital Signal Processor) and MCU (Microcontroller Unit), combining DSP’s high-speed computation with MCU’s superior I/O control. This dual-processing approach outperforms single DSP or 32-bit microcontrollers, ensuring exceptional control accuracy. Built-in hardware modules for motor control, such as PWM and QEI, enhance system performance, guaranteeing safe and stable operation.

3. Parallel Hardware-Based Sampling

A key feature of this system is its specialized ASIC chip, enabling synchronous sampling of all load cells signals. This innovation prevents asynchronous loading and deformation errors, delivering higher precision in test results.

4. Position Pulse Signal Filtering

The optical encoder position capture module includes a built-in 24-stage filter, shaping and filtering pulse signals to prevent miscounts caused by signal interference. This ensures accurate position tracking and stable system performance.

5. Low-Level Hardware Control Optimization

The DSC-TT system utilizes ASIC chips to handle peripheral functions, such as sampling and condition monitoring, reducing communication delays. With dedicated PID calculation hardware, it significantly improves control response speed, allowing real-time closed-loop control at the system’s core level. This ensures faster adjustments, higher precision, and superior overall stability.

Performance Characteristics of DSC-10TT

The system features a Windows-compatible user interface with real-time curve display and processing, providing precise monitoring and analysis. Its graphical visualization ensures intuitive test interpretation, while the modular software structure enhances ease of use. Data storage and management are based on an MS-ACCESS database, allowing for efficient organization and retrieval. Additionally, the system offers seamless compatibility with Microsoft Office, enabling easy data export and reporting for streamlined workflow integration.

The system includes a grading management mode for user authority, where each user gains access to specific operation modules based on their permissions. The super administrator has full control over user access, assigning different functions to operators as needed.

With comprehensive testing management capabilities, users can configure testing units, create customized programs based on various standards, and generate reports that comply with industry requirements. The system also provides real-time status updates, displaying equipment conditions, operation steps, and extensometer switching status.

For curve analysis, users can choose from multiple curve types such as load-deformation and load-time, displaying and comparing multiple curves in real-time using different colors. The system supports zooming into specific curve sections for detailed analysis, automatic or manual feature point selection, and labeled curves for test reports.

To prevent data loss, test results are automatically saved, with a fuzzy query function allowing quick retrieval based on different conditions. Users can also merge and compare data from tests conducted at different times. A built-in backup feature ensures data security.

The software is built on an MS-ACCESS database, offering seamless integration with Microsoft Office. Reports can be saved in Word or Excel formats, and raw data can be accessed for material research and analysis.

For automated test calculations, an extensometer can capture key parameters such as ReH, ReL, Rp0.2, Fm, Rt0.5, Rt0.6, Rt0.65, Rt0.7, Rm, and E, with results customizable and printable in graphical form.

The system also features an automatic extensometer removal function, detecting the transition from yield to displacement collection and alerting users when removal is possible.

Additional automation features include an automatic return function, bringing the moving crosshead back to its initial position after testing, and automatic calibration, adjusting load and elongation based on standard inputs.

Finally, the system offers full-range measurement without classification, featuring modular electrical hardware for easy expansion and maintenance, along with an automatic range switch, adjusting display curves dynamically based on test force and deformation.

| Measurement Parameters | |

|---|---|

| Maximum test force | 100 kN / 22,500 lb.f (can add load cells to extend the force range) |

| Accuracy class | 0.5 |

| Measuring range of test force | 0.2%~100%FS (full scale) |

| Indicating error of test force | Within ±0.5% of indicating value |

| Resolution of test force | ±1/300000 of maximum test force, grade unchanged and resolution unchanged in whole process |

| Measuring range of deformation | 0.2%~100%FS |

| Indicating error of deformation | Within ±0.5% of indicating value |

| Resolution of deformation | 1/300000 of maximum deformation |

| Indicating error of displacement | Within ±0.5% of indicating value |

| Resolution of displacement | 0.025μm |

| Control Parameters | |

| Adjustable range of force control rate | 0.005~5%FS/s |

| Control accuracy of force control rate | When rate is less than 0.05%FS/s, within ±2% of setting value; When rate is no less than 0.05%FS/s, within ±0.5% of setting value. |

| Adjustable range of deformation rate | 0.005~5%FS/s |

| Control accuracy of deformation rate | When rate is less than 0.05%FS/s, within ±2% of setting value; When rate is no less than 0.05%FS/s, within ±0.5% of setting value. |

| Adjustable range of displacement rate | 0.001~500mm/min |

| Control accuracy of displacement rate | When rate < 0.5mm/min, within ±1% of setting value; When rate ≥ 0.5mm/min, within ±0.2% of setting value |

| Other Parameters | |

| Effective testing width | 600mm |

| Effective distance of tension | 690mm (including wedge tensile fixture and can be custom-made according to user’s requirements) |

| Removable distance of crosshead | 1200mm |

| Size of Main Unit (length x width x height) | (1070 × 790 × 2180) mm |

| Weight of Main Unit | 1000Kg |

| Voltage | 380V, 50Hz, 2kW |

Configuration

1. Main Frame – 100kN Door Structure

- Machine Frame: TTM series frame (one set)

- Ball Screws: High-precision, zero-clearance (two pieces)

2. Control & Measurement System

- Servo motor, servo speed regulation and control system (one set)

- Synchronous Belt (one set)

- Load cells: 100kN capacity (one piece)

- Electronic Extensometer: Gauge length: 50mm, Deformation: 10mm

- DSC-10TT Full Digital Closed-Loop Measurement & Control System (one set)

- Load Measurement System

- Displacement Measurement System

- Deformation Measurement System

- DSC-10TT Software (English version)

- Remote Control Unit: Equipped with an LCD screen for real-time monitoring of equipment status, testing force, and displacement. Magnetic attachment allows flexible positioning on the frame (one piece).

- PC (1 piece)

- Printer (HP Color Inkjet, A4) (one piece)

3. Grips (Customizable to Customer Requirements)

- Wedge Tensile Grips:

- Jaw Sizes: Flat 0-10mm, 10-20mm (One set per size)

- V: Ø8-Ø16mm, Ø16-Ø26mm (One set per size)

- Compression Plates: Plate Diameter Ø160mm (one set)