Electromechanical Universal Testing Machine - 5kN UTM - Single Column Universal Testing Machine TTM-5L

5kN UTM - Single Column Universal Testing Machine TTM-5L

5kN UTM - Single Column Universal Testing Machine TTM-5L is designed for precise static property testing of various materials such as plastics, rubber, paper, textile, non metals and composites upto maximum of 5kN force. It performs tensile, compression, bending, shearing, peeling, tearing, loading, relaxation, and reciprocating tests.

This machine automatically calculates parameters such as ReH, ReL, Rp0.2, Fm, Rt0.5 , Rt0.6, Rt0.65, Rt0.7、Rm, E. It conducts tests and generates data in compliance with ISO, ASTM, and DIN standards.

- Calibration of load measurement instruments for uniaxial testing machines

- Verification and calibration of force-measuring systems in tension/compression testing machines

- Tensile testing of metallic materials at room temperature

- Tensile stress-strain properties of vulcanized or thermoplastic rubber

- Tensile properties of plastic films

- 180° peel test for flexible-to-rigid adhesive bonds

- Shear impact strength test for adhesive bonds

Mechanical Framework and Design

The main frame features a single-arm structure, consisting of a base, three columns, and a screw. Its transmission loading system uses an AC servo motor with a synchronous cog belt speed reducer, which drives a high-precision ball screw to control the moving crosshead for accurate loading. This design ensures a modern appearance, excellent stability, high rigidity, precise control, efficient performance, low noise operation, and energy-saving, eco-friendly benefits.

Control and Measurement System

This machine uses the advanced DSC-10TT full-digital closed-loop control system for precise measurement and control. A computer manages the testing process, dynamically displaying curves and processing data. After testing, users can zoom in on the curve for reanalysis and data editing using the figure processing module. Its performance meets top international standards.

-

Enables precise displacement, deformation, and speed closed-loop control, allowing real-time adjustments to testing speed and methods for greater flexibility and expanded testing capabilities.

-

Multi-layer protection system with both software and hardware safeguards, including overload, overcurrent, overpressure, undervoltage, overspeed, and limit protections, ensuring operational safety.

-

Equipped with three high-speed 24-bit A/D conversion channels, delivering an effective resolution of ±1/300,000, maintaining consistent accuracy throughout the testing process.

-

Utilizes USB or serial communication for stable and reliable data transmission with strong anti-interference capabilities.

-

Features three pulse signal capture channels—one for displacement and two for large deformation—along with advanced quadruple frequency technology, increasing effective pulse count fourfold and achieving a maximum capture frequency of 5MHz.

-

Incorporates a digital-driven servo motor, supporting PWM output frequencies ranging from a minimum of 0.01Hz to a maximum of 5MHz for precise control.

Key Benefits of the Control and Measurement System

-

Next-Generation Digital Control

The DSC-10TT full digital closed-loop control system is a newly developed, advanced control system designed for testing machines. It features state-of-the-art servo motor control chips and a multi-channel data acquisition and processing module, ensuring high-speed, precise control and consistent sampling. The system primarily relies on hardware modules to enhance stability and reliability. -

High-Efficiency Professional Control Platform

DSC-TT integrates DSP (Digital Signal Processor) and MCU (Microcontroller Unit), combining DSP’s high-speed computing capabilities with MCU’s powerful I/O control. This hybrid architecture outperforms single DSP or 32-bit microcontroller systems. The system includes essential motor control modules, such as PWM (Pulse Width Modulation) and QEI (Quadrature Encoder Interface), ensuring reliable, stable operation. -

Parallel Sampling for Enhanced Accuracy

A key innovation in DSC-10TT is its parallel sampling mode, made possible by a specialized ASIC chip. This technology enables synchronous signal sampling across all load cells, preventing asynchronous issues in load and deformation measurements, which were common in previous-generation systems. -

Advanced Position Pulse Filtering

The optical encoder position capture module utilizes a dedicated hardware module with a built-in 24-stage filter to refine pulse signals. This prevents miscounting due to signal interference, ensuring high position accuracy and stable performance of the pulse capture system. -

Optimized Control Execution

The DSC-10TT system offloads sampling, condition monitoring, and communication to specialized ASIC chips, allowing the main processor to focus on PID (Proportional-Integral-Derivative) control calculations. This architecture enhances system reliability, accelerates response time, and enables precise, real-time closed-loop control at the system’s core level.

Performance Characteristics of DSC-10TT

The user interface is designed for Windows systems, offering real-time curve display and processing with a graphical, intuitive layout. The software features a modular structure, ensuring flexibility and ease of use. Data storage and processing are managed through an MS-ACCESS database, allowing seamless integration with Microsoft Office applications for efficient data management and reporting.

-

User Access Management

The system supports role-based access control, granting users specific operational permissions upon login. The super administrator holds full control, managing user access and assigning different modules based on roles. -

Comprehensive Testing Management

Users can freely configure testing parameters and create custom test programs based on specific standards. The system ensures compliance with selected standards, displays real-time equipment status (e.g., operating state, program steps, and extensometer switching), and generates standard-compliant test reports. -

Powerful Curve Analysis

The system supports various curve types (e.g., load-deformation, load-time) with real-time display. Users can compare curves within the same test group using different colors, zoom in on specific sections for analysis, label key feature points, and choose points manually or automatically for comparison. Labeled curves can be printed in test reports. -

Automatic Data Storage & Retrieval

Test data is automatically saved to prevent loss from unexpected incidents. The system enables fuzzy search for quick data retrieval and redisplays test results based on conditions. It also allows users to combine and analyze data from multiple test sessions and supports data backup for added security. -

MS-ACCESS Database Integration & Expandability

Built on an MS-ACCESS database, the DSC-10TT software seamlessly integrates with Microsoft Office, enabling test reports to be saved in Word or Excel formats. The database structure allows users to access and analyze raw data for material research, maximizing the utility of test measurements. -

Automatic Test Result Calculation

When an extensometer is added, the system automatically calculates key parameters such as ReH, ReL, Rp0.2, Fm, Rt0.5, Rt0.6, Rt0.65, Rt0.7, Rm, E, and others. Users can freely configure parameters and generate corresponding graphical outputs. -

Automated Extensometer Removal Notification

The software automatically detects yield completion and switches from deformation to displacement collection. A notification alerts users that "deformation switch is complete, extensometer can be removed." -

Automatic Return Function

After testing, the moving crosshead automatically returns to its initial position for efficiency and ease of use. -

Automated Calibration

The system automatically calibrates load and elongation according to the applied standards, ensuring precision and accuracy. -

Flexible Measuring Range & Adaptive Display

- Modular Design: The system supports various interchangeable accessories, offering flexibility for future expansions and easy maintenance.

- Automatic Range Adjustment: The display automatically adjusts the curve range based on test force and deformation changes, ensuring accurate real-time visualization.

| Measurement Parameters | |

|---|---|

| Maximum test force | 5kN / 1,125 lb.f (can add load cells to extend the force range) |

| Accuracy class | 0.5 |

| Measuring range of test force | 0.2%~100%FS (full scale) |

| Indicating error of test force | Within ±0.5% of indicating value |

| Resolution of test force | ±1/300000 of maximum test force, grade unchanged and resolution unchanged in whole process |

| Measuring range of deformation | 0.2%~100%FS |

| Indicating error of deformation | Within ±0.5% of indicating value |

| Resolution of deformation | 1/300000 of maximum deformation |

| Indicating error of displacement | Within ±0.5% of indicating value |

| Resolution of displacement | 0.025µm |

| Control Parameters | |

| Adjustable range of force control rate | 0.005~5%FS/s |

| Control accuracy of force control rate | When rate is less than 0.05%FS/s, within ±2% of setting value; When rate is no less than 0.05%FS/s, within ±0.5% of setting value. |

| Adjustable range of deformation rate | 0.005~5%FS/s |

| Control accuracy of deformation rate | When rate is less than 0.05%FS/s, within ±2% of setting value; When rate is no less than 0.05%FS/s, within ±0.5% of setting value. |

| Adjustable range of displacement rate | 0.001~500mm/min |

| Control accuracy of displacement rate | When rate < 0.5mm/min, within ±1% of setting value; When rate ≥ 0.5mm/min, within ±0.2% of setting value |

| Other Parameters | |

| Effective distance of tension | 700mm (can be custom-made according to user’s requirements) |

| Removable distance of crosshead | 900mm |

| Size of Main Unit (length x width x height) | (510 × 510 × 1580) mm |

| Weight of Main Unit | 150Kg |

| Voltage | 220V, 50Hz, 0.5kW (110V is also available) |

Configuration

1. Main Unit: Single-Column Structure

- Frame: TTM series frame (1 set)

- Ball Screw: High-precision, zero-clearance (TBI, 1 piece)

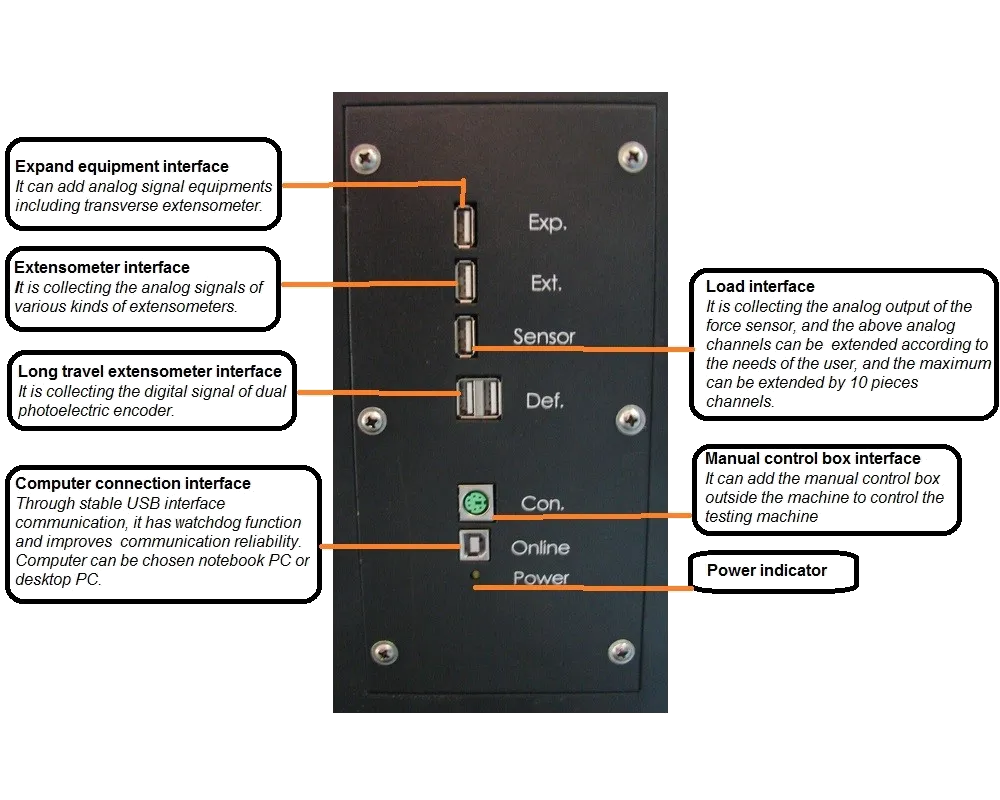

2. Control & Measurement System

- Servo Motor & Speed Control System: (1 set)

- Synchronous Belt: (1 set)

- Load celss: 5kN capacity (1 piece)

- DSC-10TT Digital Closed-Loop Control System (1 set)

- Load Measurement System

- Displacement Measurement System

- Deformation Measurement System

- DSC-10TT English Software

- Remote Control Unit:

- LCD screen with real-time display of equipment status, testing force, and displacement, magnetic backing for easy attachment anywhere on the frame (1 piece)

- PC (1 piece)

- Printer: HP color inkjet, A4 format (1 piece)

3. Grips (Customizable per customer requirements)

- Wave Grip Set (1 set)