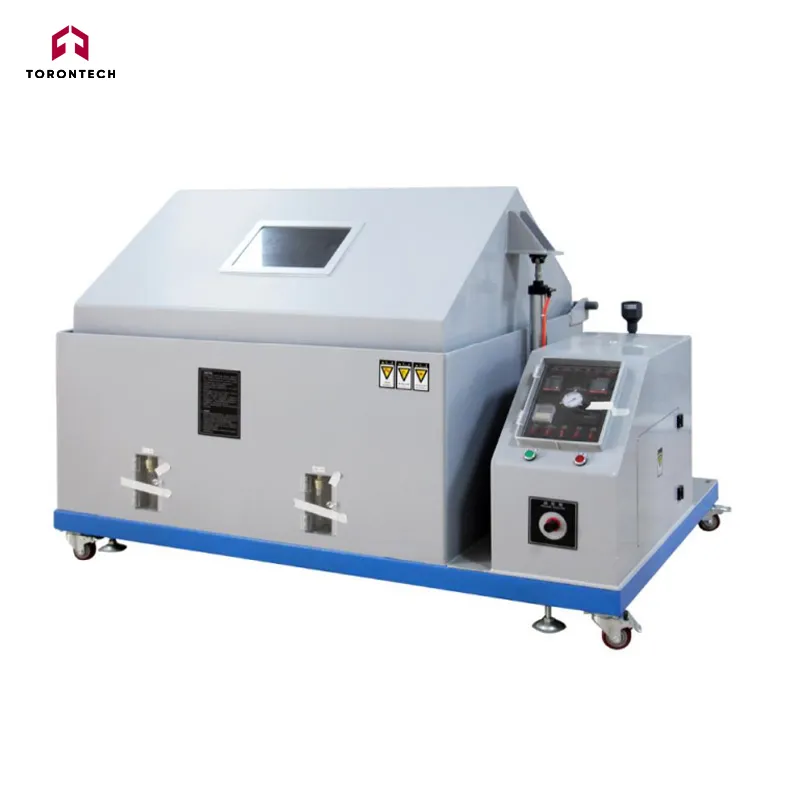

Salt Spray Corrosion Test Chamber TTSS Series

Salt Spray Corrosion Test Chamber is different from the basic salt spray test chamber. Cyclic corrosion test chamber exposes samples to a series of different environments in repetitive cycles that incorporate temperature, humidity, salt spray and dry.

Chamber material

- Material Thickness: Models below 90 feature a 5mm thickness, while models above 90 use 8mm gray-white impact-resistant PVC board. These materials offer high-temperature resistance up to 85°C and are highly corrosion-resistant.

- Support Frame: Constructed with a ¢10mm glass fiber rod that resists corrosion. The V-shaped plastic steel frame and fiber rod are angled to keep the test object positioned at a 15–30 degree incline.

- Pressure Barrel: Crafted with a seamless weld using 2.0mm SUS304 stainless steel plate, ensuring durability and reliability.

- Heating System: Equipped with a titanium alloy electric heating tube, designed for exceptional corrosion resistance and longevity—lasting 3–5 years longer than standard stainless steel heating tubes.

- Transparent Cover: Made with 5mm YLIS acrylic sheet, offering meticulous craftsmanship, an attractive appearance, and excellent transparency.

- Water-Gas Separation Design: Features a specialized structure to maintain experimental temperatures effectively. This reduces the need for frequent water replenishment in the pressure tank caused by brine concentration loss and prevents tank leakage.

Touch screen control system (Optional)

Equipped with a 7-inch touch controller, this system supports both constant-value experiments (continuous or steady temperature) and programmable salt spray experiments (intermittent or cyclic). Its versatile design offers multiple functions to meet diverse experimental requirements.

Key Features:

- High-Precision Temperature Control: Includes a PID automatic calculation module and a high-stability platinum temperature probe with an accuracy of ±0.3°C.

- Timing Mode: Offers hour-based timing options for flexible operation.

- User-Friendly Interface: All controls are conveniently placed on a single panel for ease of use and a clear overview.

- Data Storage and Analysis: Accurately stores temperature data during experiments, ensuring intuitive and precise analysis.

This advanced controller simplifies operations while maintaining exceptional accuracy and reliability, catering to various salt spray testing needs.

Water filling system

This system features both automatic and manual water filling capabilities, ensuring uninterrupted experiments even when the water level is low.

Key Features:

- Dual Functionality: Offers the flexibility of automatic or manual water replenishment.

- Continuous Operation: Keeps experiments running smoothly without interruptions.

- Easy Integration: The automatic water replenishment function requires only a connection to a tap water pipe.

- Adaptable Design: Designed to meet diverse environmental requirements.

This system provides a reliable and efficient solution for maintaining optimal water levels during experiments.

Heating Method

The salt spray experiment utilizes direct steam heating, offering several key advantages:

- Rapid Heating: Ensures a quick temperature rise, minimizing preparation time.

- Uniform Temperature Distribution: Maintains consistent conditions throughout the experiment.

- Reduced Standby Time: Enhances efficiency by shortening waiting periods.

This method ensures reliable performance and optimal conditions for salt spray testing.

Control method

This system features a rocker-type standard operation design, combined with advanced functionalities for improved efficiency and user convenience:

- Comprehensive Fault Detection: Includes an early warning system that alerts users immediately in case of a fault.

- Manual Demist Function: Enables the removal of accumulated salt mist during experiments, ensuring clear visibility of the test environment and placement of the product.

- Spray Mode: Operates in continuous spray mode for consistent performance.

These features ensure smooth operation, enhanced safety, and optimal experimental conditions.

Protection devices

This system is equipped with robust safety features to ensure uninterrupted and damage-free operation:

- Double Over-Temperature Protection: Uses Italy EGO technology to automatically cut off heating power if the temperature control meter or heating system fails, preventing high-temperature damage.

- Double Low Water Level Protection: Safeguards against dry burning and damage to heating pipes and pressure barrels by monitoring water levels.

- Overload and Short Circuit Protection: Protects the instrument and its electronic control components from damage caused by electrical abnormalities.

- Low Salt Level Reminder: Alerts users when the brine in the experiment's real brine bucket is running low, avoiding disruptions or abnormalities during testing.

These advanced safety measures ensure reliability and longevity while maintaining optimal experimental conditions.

Measuring cylinder

A built-in fog collection tube is used. Compared with the traditional external type, it is less likely to be damaged.

Spay nozzle

- Quartz Glass Nozzle: Ensures no crystallization even after 4000 hours of use, maintaining consistent spray quality.

- Conical Diffuser: Equipped with a conical diffuser that guides the fog and adjusts the spray amount, ensuring even distribution of the mist.

Sealing method

The inner and outer chambers are connected with sealing grooves and sealed with water, effectively preventing salt mist from leaking out during the experiment. This design ensures a controlled environment and minimizes the risk of contamination or interference.

Control panel main parts

| Name | Qty |

|---|---|

| Temperature controller | 1 pc |

| Timing controller | 1 pc |

| Timer | 1 pc |

| Platinum resistance | 2 pcs |

| Spray solenoid valve | 1 pc |

| Solid state relay | 2 pcs |

| Intermediate relay | 3 sets |

| Heating tube | 1 pc |

| Pressure regulating valve | 1 pc |

| Air filter | 1 pc |

Appendix:

| Parts Name | Qty | Parts Name | Qty |

|---|---|---|---|

| V-shape sample holder | 1 group | O-shape sample holder | 1 group |

| Sodium chloride | 2 bottles | 5000 measuring bucket | 1 pc |

| Hydrometer | 1 pc | Operation manual | 1 pc |

| Model | TTSS-60 | TTSS-90 | TTSS-120 | TTSS-160 | TTSS-200 |

|---|---|---|---|---|---|

| Internal Dimension (W) | 600 | 900 | 1200 | 1600 | 2000 |

| Internal Dimension (D) | 450 | 600 | 850 | 1000 | 1200 |

| Internal Dimension (H) | 400 | 500 | 500 | 550 | 600 |

| External Dimension (W) | 1130 | 1460 | 2200 | 2600 | 3000 |

| External Dimension (D) | 630 | 910 | 1200 | 1450 | 1650 |

| External Dimension (H) | 1070 | 1280 | 1450 | 1550 | 1600 |

| Test Chamber Volume (L) | 108 | 270 | 480 | 800 | 1440 |

| Brine Tank Capacity (L) | 15 | 25 | 40 | ||

| Max Current (A) | 5 | 12 | 15 | 18 | 22 |

| Maximum Power Consumption (KW) | 1.5 | 2.5 | 3.5 | 5 | 7 |

| Power | AC220V, 50HZ | AC380V, 50HZ | |||

| Ambient Temperature and Humidity | Temperature below 35°C, <85%RH | ||||

| Test Area Temperature | Salt water test method (NSS ACSS): 35°C ±1°C / Corrosion resistance test method (CASS): 50°C ±1°C | ||||

| Pressure Barrel Temperature | Salt water test method (NSS ACSS): 47°C ±1°C / Corrosion resistance test method (CASS): 63°C ±1°C | ||||

| Salt Water Solubility | Add 0.26g copper chloride (CuCl2 2H2O) per liter to 5% sodium chloride solution or 5% sodium chloride solution | ||||

| pH Value | 6.5~7.2, 3.0~3.2 | ||||

| Compressed Air Pressure | 1.00 ± 0.01kgf/cm² | ||||

| Spray Volume | 1.0~2.0ml/80cm²/h (collect for at least 16 hours and take the average value) | ||||

| Inner Chamber Material | Corrosion-resistant, aging resistant, high-strength PVC board | ||||

| Heater | Corrosion-resistant U-shaped titanium pipe | ||||

| Temperature Controller | LED digital display temperature controller, touch screen controller | ||||

| Spray Method | Continuous and intermittent spray | ||||

| Demisting Device | No | Equipped | |||

| Safety Devices | Over-temperature protection switch, leakage protection, status warning light | ||||

1. Temperature Range

- Laboratory Temperature: 35°C–50°C (can be set arbitrarily)

- Pressure Barrel Temperature: 47°C–63°C (can be set arbitrarily)

2. Heating Rate

- Laboratory: Normal temperature to 35°C in about 35 minutes

- Pressure Barrel: Normal temperature to 47°C in about 15 minutes

3. Temperature Control Accuracy: ±0.3°C

- Distribution Uniformity: ≤2°C (Complies with international standards)

4. Brine Concentration & pH Value Requirements

- Neutral Test: pH 6.0–7.0

- Acid Test: pH 3.0–3.1

- Spray Solution pH:

- Neutral: 6.5–7.2

- Acid: 3.1–3.3

Note: Carbon dioxide loss in the solution during spraying may cause pH value changes. To minimize this, heat the solution to above 35°C before placing it in the test equipment, or prepare the solution with fresh boiling water. This prevents pH fluctuations. For acid tests or copper accelerated salt spray tests, ensure the pH of the spray solution is adjusted to 2.8–3.0 and verified.

5. Standards Compliance

The equipment meets the following product and testing standards:

- GB/T2423.17-2008/IEC 60068-2-11-1981 Salt Spray Test Method

- ASTM B117-2009 Salt Spray Test

- JIS H8502 Salt Spray Test Method

- GB/T10125-2012/ISO 9227-2006 Salt Spray Test Method

- GB-T5170.8-2008 Environmental Test Equipment for Electrical and Electronic Products – Salt Spray Test Equipment

- GB-T5170.11-2008 Corrosive Gas Test Equipment

- ISO 9227 Salt Spray Test

- GB-T10587-2006 Technical Conditions of Salt Spray Test Chamber

6. Power Supply Requirements

- AC220V single-phase two-wire + protective grounding or AC380V three-phase five-wire system

- Voltage Fluctuation Range: ±10%

- Frequency Fluctuation Range: 50 ± 0.5Hz

- Users must configure an air or power switch with the appropriate capacity for the equipment at the installation site. This switch should independently control the equipment’s use.

7. Air Source Requirements

- Air Compressor: Minimum power of 2.5P

- Air Storage Tank Capacity: 60L or above

This comprehensive specification ensures optimal operation and compliance with international testing standards.