Sand Dust Test Chamber

Sand Dust Test Chamber replicates the impact of natural elements like sand, wind, and dust on products and materials, which can result in significant economic losses annually. Common effects include corrosion, fading, deformation, reduced strength, swelling, mold growth, and more. For electrical products, sand and dust can lead to short circuits, increasing the risk of fires. This makes conducting a dustproof test on enclosures an essential step to ensure product safety and durability.

It is designed for dust testing of outdoor lighting, household appliances, automotive components, and other electronic and electrical products.

Standard Test

The Sand and Dust Test Chamber adheres to the following standards:

- IEC 60529:1989 + A1:1999 + A2:2013: "Degrees of protection provided by enclosures (IP Code)."

- GB 4208-2008: "Enclosure Protection Level (IP Code)" clauses 13.4 and 13.5, including diagrams 3.

- GB 7000.1: "Lamps Part 1: General Requirements and Tests," sections 9.2.1 and 9.2.2, along with the specifications outlined in Figure 6.

These compliance measures ensure precise testing and reliable evaluation of enclosure protection levels.

Structural Features

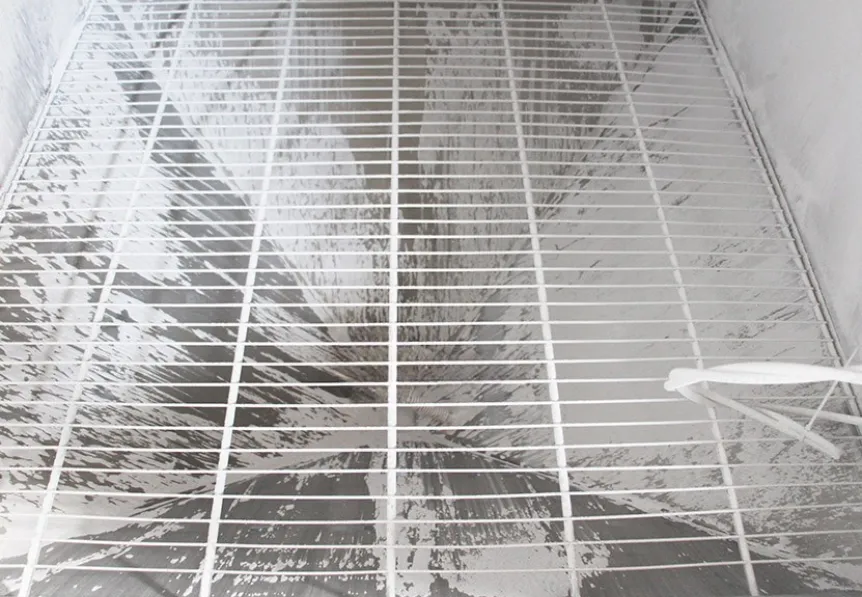

The inner chamber is constructed from SUS#304 stainless steel with a thickness of 1.2mm. Its fully welded design ensures excellent sealing and resistance to cracking.

The external structure is made of 1.5mm cold-rolled steel that undergoes brushing, polishing, and painting treatments, making it highly resistant to scratches.

Polyurethane foam with a thickness of 100mm is used for insulation, ensuring superior thermal performance.

The door features a double silicone rubber seal for optimal airtightness.

The observation window is made of four layers of tempered glass, with customizable dimensions. To prevent frosting during low-temperature operations, heating wires are embedded within the window for efficient defrosting.

| Model | ToronSDC-500 | ToronSDC-1000 | ToronSDC-2000 |

| Volume | 500L | 1000L | 2000L |

| Internal Dimension W*H*D(mm) | 800*800*800 | 1000*1000*1000 | 1000*2000*1000 |

| External Dimension W*H*D(mm) | 1450*1700*1000 | 1650*1900*1200 | 1650*2900*1200 |

| Dustfall form | Free fall dust type :The dust is blown to 1/5 of the tank top by centrifuge to make it free settling | ||

| Dust blowing:Bottom air blast , three grades pressure is adjustable | |||

| Standard configuration | With dust drying device, vibrator, sample holder, observation window (door) | ||

| Safety protection | Overload breaking protection, earthing protection, etc. | ||