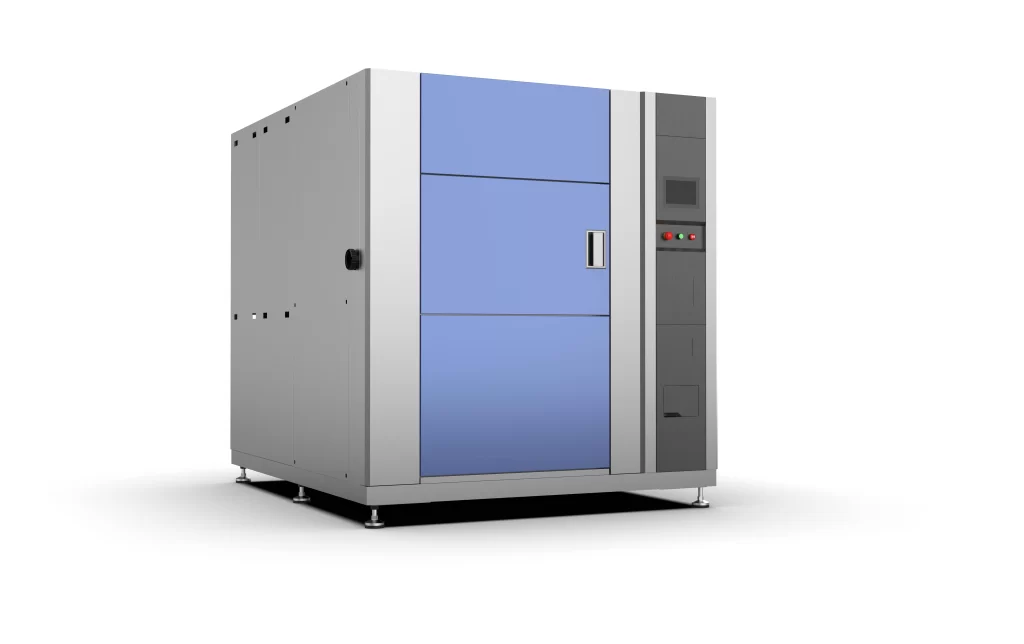

3-Zone Thermal Shock Chamber

Torontech’s 3-Zone Thermal Shock Chambers take testing to the next level by incorporating hot, cold, and ambient zones. This advanced design allows for more complex thermal cycling simulations, offering the flexibility to test materials and components under a broader range of conditions. Samples are automatically moved between the three zones to replicate real-world environmental stress more accurately. These chambers are ideal for applications requiring precise testing, such as in the electronics, aerospace, and automotive industries. Torontech’s 3-zone thermal shock chambers are engineered for fast transition times, exceptional temperature uniformity, and ease of operation, ensuring reliable results for even the most demanding thermal shock testing requirements.

| Model No. | ToronTSC3-64 | ToronTSC3-100 | ToronTSC3-200 | ToronTSC3-300 | ToronTSC3-500 | ToronTSC3-1000 |

|---|---|---|---|---|---|---|

| Test Space Volume (Liters) | 64 | 100 | 200 | 300 | 500 | 1000 |

| Inner chamber size W×H×D(mm) | 400×400×400 | 500×450×450 | 650×460×670 | 850×600×650 | 1000×750×700 | 1000×1000×1000 |

| Exterior chamber size W×H×D(mm) | 1420×1930×2000 | 1520×1990×2050 | 1620×1980×2140 | 1840×1862×2100 | 1900×1962×2200 | 1900×2150×2200 |

| High Temp. Chamber | +60°C to +200°C | |||||

| Pre-heating time | from normal temperature RT to ~ +200°C within 30 min | |||||

| Low Temp. Chamber | A: -55°C to -10°C B: -70°C to -10°C D: -80°C to -10°C |

|||||

| Pre-cooling time | from normal temperature RT to -55°C / -70°C / -80°C within 60 min | |||||

| Temp. shock range | A: -40°C to +150°C B: -55°C to +150°C D: -65°C to +150°C |

|||||

| Recovery time | ≤ 5 min | |||||

| Temp. fluctuation | ±0.5°C | |||||

| Temp. uniformity | ≤ 2.0°C | |||||

| Exterior chamber material | High-quality carbon steel with painting | |||||

| Interior chamber material | SUS304 matte stainless steel plate | |||||

| Insulation material | Rigid polyurethane foam insulation | |||||

| Refrigeration system | Water cooled | |||||

| Semi-hermetic compressor, cascade refrigeration system, Eco-friendly refrigerant | ||||||

| Controller | LCD Touch Screen Controller with PID control | |||||

| Safety protection device | NFB (No fuse breaker), over pressure, over heat and over current protectors for compressor, over temperature protectors, over load protector of fan, dry heat protector, short of water protector | |||||

| Standard accessory | Cable port(Φ50mm)×2, shelves×2 Mobile Casters with foot cups | |||||

| Ambient temp. | +5 to +35°C | |||||

| Voltage | 380V AC 30 50Hz | |||||

| Customization service | Non-standard or special requirements can be customized. | |||||