Zirconia Sintering Lifting Furnace TT-LF-150-1700

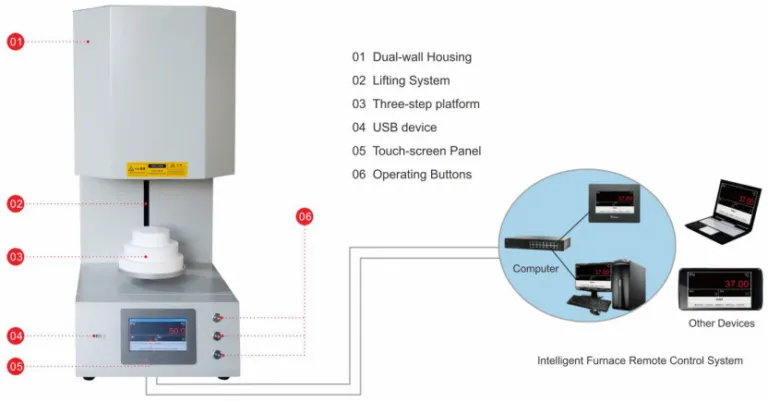

Zirconia Sintering Lifting Furnace TT-LF-150-1700, also known as a denture crystallization furnace, uses 1800°C pure silicon molybdenum rods as heating elements to ensure clean, contaminant-free crystallization and sintering of zirconia dental crowns. It features a high-uniformity temperature field and a bottom-loading automatic lifting mechanism, making material loading and unloading simple and efficient. Designed for use in dental clinics and denture labs, it delivers consistent results for zirconia crown sintering and crystallization.

| Model No. | TT-LF-150-1700 |

| Chamber Volume | 3L |

| Continuous Temperature | 1600℃ |

| Max Temperature | 1700°C |

| Voltage | 220V/4kw (110V is also available) |

| Heating Element | Molybdenum Disilicide (MOSi2) heater |

| Temperature Precision | ±1°C |

| Thermocouple | B type |

Key Features

- 7-Inch Embedded Touchscreen Interface:

Intuitive menu system with real-time process curve display. Data export supported. Up to 15 sintering profiles from various zirconia block brands can be preloaded and accessed instantly. Each profile allows up to 30 programmable segments for full customization. - Clean, High-Performance Insulation:

Lined with high-purity alumina ceramic fiber for exceptional thermal insulation. Free from contaminants, with iron content ≤440 ppm to maintain material purity. - Contamination-Free Heating Elements:

Features pure U-shaped silicon molybdenum rods for heating, which prevent secondary contamination during sintering and support rapid sintering of single crowns. - Optimized Furnace Design:

Cylindrical chamber with annular heating structure ensures a uniform temperature field. This design enhances the consistency and permeability of zirconia crowns. - Stable Bottom-Lift Mechanism:

Automatic bottom-loading system with a precision screw drive and high-accuracy linear guide rails ensures smooth, shake-free lifting and easy operation. - High Capacity for Batch Processing:

Accommodates two φ100mm sintering trays simultaneously, allowing processing of approximately 25–50 zirconia crowns per cycle—ideal for high-throughput workflows. - Integrated Safety System:

Modular design includes audio-visual alarms for over-temperature, overload, and thermocouple failure. The system automatically activates protective responses to ensure equipment safety.

|

Product Model |

Chamber Size(mm) |

Volume |

Max Temperature |

Working Temperature |

Voltage |

Power |

Heating Element |

Temperature control accuracy |

|

TT-LF-120-1200 |

Φ120×120 |

2L |

1200℃ |

1100℃ |

220V (110V is also available) |

2KW |

HRE |

±1℃ |

|

TT-LF-150-1200 |

Φ150×150 |

3L |

1200℃ |

1100℃ |

220V (110V is also available) |

3KW |

HRE |

±1℃ |

|

TT-LF-200-1200 |

Φ200×200 |

6L |

1200℃ |

1100℃ |

220V (110V is also available) |

4KW |

HRE |

±1℃ |

|

TT-LF-300-1200 |

Φ300×300 |

20L |

1200℃ |

1100℃ |

380V |

6KW |

HRE |

±1℃ |

|

TT-LF-120-1400 |

Φ120×120 |

2L |

1400℃ |

1350℃ |

220V (110V is also available) |

3KW |

SIC |

±1℃ |

|

TT-LF-150-1400 |

Φ150×150 |

3L |

1400℃ |

1350℃ |

220V (110V is also available) |

4KW |

SIC |

±1℃ |

|

TT-LF-200-1400 |

Φ200×200 |

6L |

1400℃ |

1350℃ |

220V (110V is also available) |

5KW |

SIC |

±1℃ |

|

TT-LF-300-1400 |

Φ300×300 |

20L |

1400℃ |

1350℃ |

380V |

6KW |

SIC |

±1℃ |

|

TT-LF-120-1700 |

Φ120×120 |

2L |

1700℃ |

1600℃ |

220V (110V is also available) |

3KW |

MoSi2 |

±1℃ |

|

TT-LF-150-1700 |

Φ150×150 |

3L |

1700℃ |

1600℃ |

220V (110V is also available) |

4KW |

MoSi2 |

±1℃ |

|

TT-LF-200-1700 |

Φ200×200 |

6L |

1700℃ |

1600℃ |

220V (110V is also available) |

4KW |

MoSi2 |

±1℃ |

|

TT-LF-300-1700 |

Φ300×300 |

20L |

1700℃ |

1600℃ |

380V |

8KW |

MoSi2 |

±1℃ |