Turbo Pumped Desk Carbon Coater- DCT

The Turbo Pumped Desk Carbon Coater- DCT is a turbo-pumped carbon coater designed for various applications, including FE-SEM, EDS/WDS, TEM, EBSD, and thin film applications. This high vacuum carbon coater excels at producing high-quality, uniform carbon films with fine grain sizes. These films are especially well-suited for specimens that demand high-resolution and top-quality characterization.

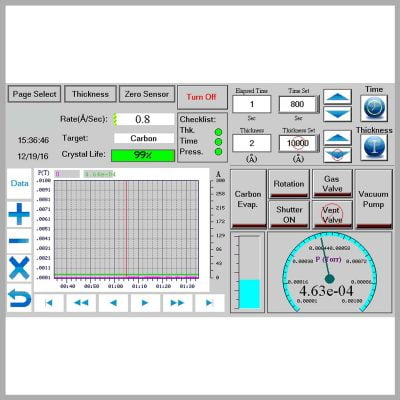

Touch Screen Control

The Desk Carbon Coater features a user-friendly 7-inch color touchscreen interface with complete automatic control and data input capabilities, making it accessible even for inexperienced users. Through this touchscreen, users can effortlessly operate the system and view vacuum levels, current readings, and deposition information in either digital data or graphical curve formats. Additionally, the system retains information on the last 300 coatings, which can be readily accessed in the history page for reference.

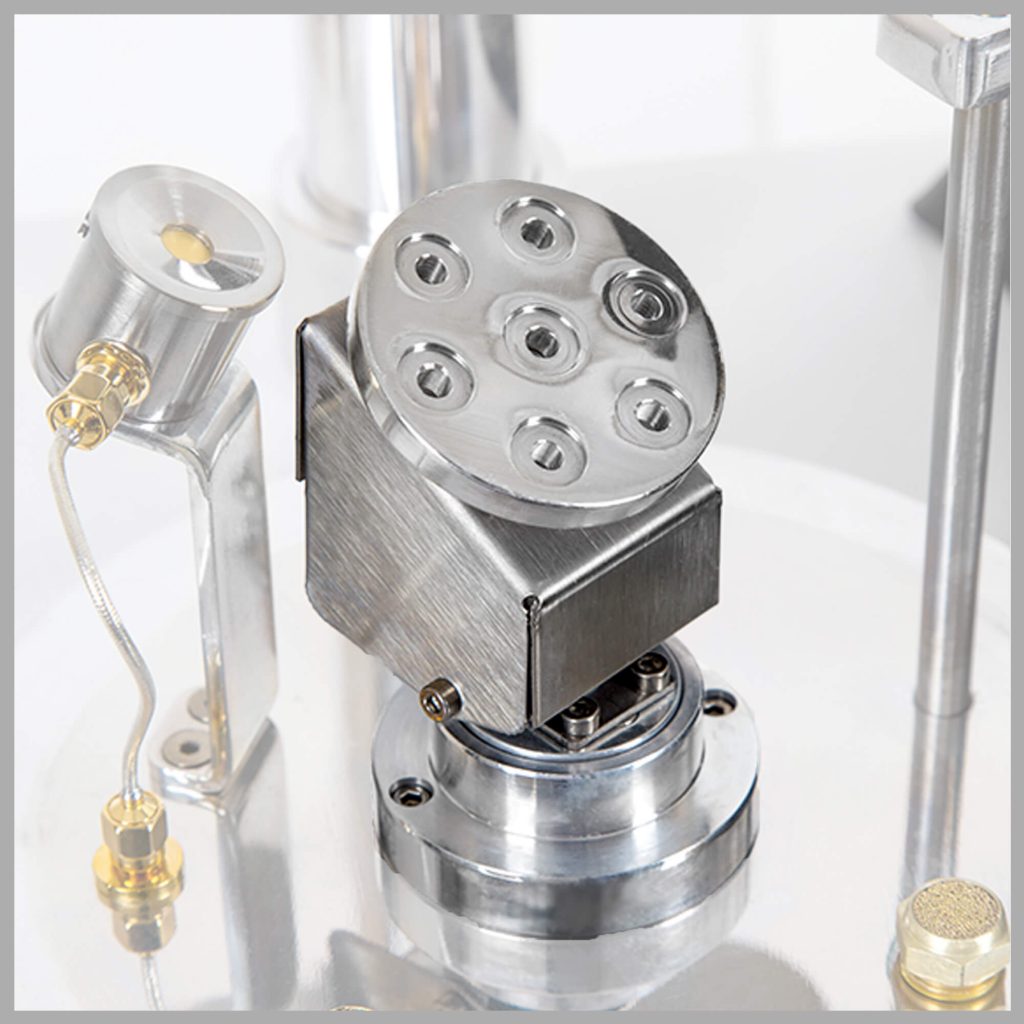

Sample Holder of Vacuum Carbon Coater

The turbo-pumped carbon coater offers versatile sample stage configurations, allowing customization based on user requirements. These sample stages are designed to be rotatable with adjustable height and are easily interchangeable. The rotary planetary sample stage, in particular, is a recommended option for achieving uniform coating, especially for porous specimens.