High Vacuum Thermal Evaporator- DTE

The High Vacuum Thermal Evaporator- DTE, or Desktop Thermal Evaporator, is a compact and cost-effective system designed for depositing thin layers of materials onto substrates. It is primarily used for research purposes and investigations through electron microscopy. The DTE is set up as a material evaporator, making it suitable for conducting experiments involving sample evaporation. This system features a small chamber and operates under high-vacuum conditions, making it ideal for quickly depositing noble metals as well as oxidizing metals.

Thermal Evaporation

The DTE comes with a high-current power supply and a low-voltage (resistive) thermal evaporation platform, making it versatile for various thermal evaporation tasks. This system enables precise control over the thermal evaporation process of a wide range of materials onto the substrate. It accommodates different types of thermal evaporation sources, including boats, baskets, and coils, which can be mounted on a single thermal source holder.

The DTE is equipped with a 1.2 kW high-current DC power supply, allowing it to deposit a thin layer of the evaporant material onto different surfaces. This capability makes it suitable for diverse applications, including SEM sample preparation.

Hardware

Automation

Clean Vacuum

Touch Screen Control

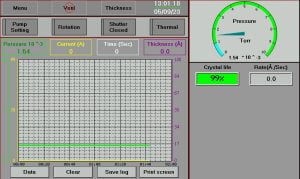

The DTE system is equipped with a 7-inch colored touch-screen panel featuring user-friendly software for controlling the deposition process data. Users can view vacuum and coating sequence information as digital data or curves displayed on the touch screen. The system also maintains records of the last 300 coatings, which can be accessed on the history page.

Sample Holder

The DTE deposition system offers flexibility in metal evaporation with two distinct configurations:

1. Upward Deposition:

2. Downward Deposition:

DTE Operation Requirements

The DTE deposition system is characterized by its small chamber, which offers advantages such as compactness, lightweight design, quick vacuuming, and budget-friendly operation. However, it's important to consider some advisory notes when using this device:

1. Ideal for Short-Term Thin Film Coatings:

2. Suitable for Low Vaporization Temperature Materials:

3. Maximum Sample Diameter Limitation:

Should these coating conditions not align with your specific requirements, we recommend exploring our DTT model, which features a larger 300 mm diameter chamber and three thermal sources.

Options and Accessories

Certainly, here are the options and accessories for the DTE Deposition System: