PLD Pulsed Laser Deposition System

Adaptable PLD Pulsed Laser Deposition System and Thermal Evaporation System – PLD-T is an advanced high vacuum thin film deposition system that allows for the deposition of various materials using both Pulsed Laser Deposition and Thermal Evaporation techniques. This system is capable of depositing intricate materials and crystalline structures onto substrates with minimal setup required.

The Pulsed Laser Deposition technique facilitates efficient non-thermal ablation, preserving the stoichiometry of the target materials. Utilizing this method, it is possible to deposit materials such as nitrides, oxides, superlattices, polymers, and composites.

Target Manipulator:

Thermal Sources:

Real-time Thickness Measurement:

User-Friendly Interface:

Plasma Cleaning:

Upgradable Software:

Sample Handling:

Motorized Boat Selection:

Substrate Heating:

Warranty and Insurance:

Thermal Evaporation Sources (Boat/Basket/Coil):

The Pulsed Laser Deposition System is adaptable to three independent heat-resistant thermal evaporation sources, which can be in the form of boats, baskets, or coils. These sources are designed for efficient material evaporation without causing contamination transfer to other materials. The length of the source holders is adjustable within the range of 5 to 10 cm, catering to specific customer requirements.

Target Manipulator:

The PLD system features a multi-target manipulator equipped to handle three targets, each with a diameter of 2 cm. The targets are of standard size, and all target manipulators are motorized, allowing for precise target rotation and positioning during the deposition process.

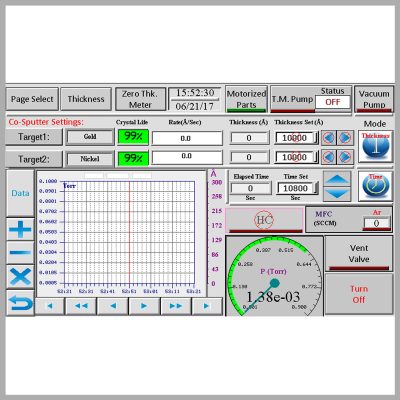

Intuitive Touch Screen Control with Vibrant Display:

The PLD-T Pulsed Laser Deposition System is designed with a user-friendly 7-inch colored touch screen, providing an intuitive interface for easy control and monitoring. The touch screen allows for fully automatic control and effortless data input, making it accessible even to users with limited experience.

Users can conveniently observe vacuum levels, current status, and deposition information displayed in both digital format and graphical curves directly on the touchscreen. Additionally, the system includes a history page where data from the last 300 coatings can be saved and reviewed for reference and analysis. This feature enhances efficiency and facilitates a seamless user experience throughout the coating process.

These specifications outline the key components and features of the Pulsed Laser Deposition & Thermal Evaporator System, highlighting its capabilities in vacuum operation, power supply, gas flow control, data analysis, and ease of use.

Options and Accessories for PLD-T:

Thermal Evaporation Sources:

Substrate Heater:

Evaporation Sources Materials:

Quartz Crystal Sensors:

Sealing Gaskets:

These options and accessories enhance the versatility and functionality of the PLD-T system, allowing for tailored and efficient thin film deposition processes while maintaining high precision and control.

Specifications of Pulsed Laser Deposition & Thermal Evaporator System:

Vacuum System:

Vacuum Measurement:

Real-time Thickness Measurement:

Power Supply:

Gas Flow Control:

Data Recording and Analysis:

Data Transfer:

Utilities:

Dimensions:

Weight: