Aeolian Vibration Tester for Conductor Cables

Aeolian Vibration Tester for Conductor Cables TT-OFCCVT is designed to perform Aeolian Vibration tests for cable conductors according to IEC 60794-1-21,IEEE 1222, IEEE 1138.

Standard

IEC 60754-2:2011 specifies the apparatus and procedure for the determination of the potential corrosivity of gases evolved during the combustion of materials taken from electric or optical fibre cable constructions by measuring the acidity (pH) and conductivity of an aqueous solution resulting from the gases evolved during the combustion. The general method specified in this standard is intended for the testing of individual components used in a cable construction. Formulae are given for the calculation of a weighted value for a combination of materials found in a specified cable. The use of this method will enable the verification of relevant requirements for either individual components or combined components of a cable construction stated in the appropriate cable specification. A simplified method is included for the testing of individual components where it is required only to demonstrate compliance with a stated performance requirement for quality control purposes. The significant technical changes with respect to the previous edition are as follows:

- Improved definition of safety requirements relating to capture of gases;

- Introduction of guidance on the preparation of test specimens for more even combustion;

- Better expression of tolerances and precision;

- Clarification of the conductivity and acidity functions;

- Improved definition of the heating procedure;

- Greater precision in the definition of the test temperature for the determination of pH value and conductivity;

- Correction of the formulae for the calculation of the test results.

IEC 60754-2:2011 has the status of a group safety publication in accordance with IEC Guide 104.

Technology Basis

Aeolian Vibration Tester for Conductor Cables is designed to simulate wind-induced vibrations in real installation conditions. It evaluates potential fatigue damage to cable components or hardware at attachment points, which may also negatively impact optical signal transmission.

Application

The purpose of this testing is to verify that conductor accessories can protect the conductor from dynamic, wind-induced bending stresses. According to industry standards, conductors under tension can vibrate in standing waves when exposed to laminar wind flows. For OPGW cables, this occurs at 4.5 m/s as per IEEE 1138, and for ADSS cables, it occurs at 16.1 km/h (4.47 m/s) as per IEEE 1222.

Within the span itself, this vibration has minimal impact on the conductor. However, at support or dead-end structures, it generates bending stresses. Although the peak-to-peak amplitude of vibration within the span is generally smaller than the conductor's diameter, long-term exposure without proper protection can lead to fatigue failures.

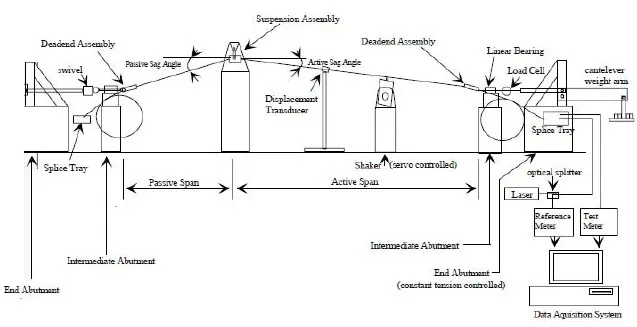

The laboratory test setup for aeolian vibration testing involved a 30-meter conductor span with dead-end assemblies on both ends and a suspension assembly at the center, secured to a rigid tower. During testing, the conductor tension was maintained at 25% RTS for OPGW and 100% MIT for ADSS using a tension beam and weight basket. A vibration shaker was used to sustain vibrations at a frequency of (830/conductor diameter in mm) Hz for 100 million cycles. Daily visual inspections of the conductor, dead-end assemblies, and suspension assemblies were conducted to monitor for potential damage.

Aeolian Vibration Tester for Conductor Cables is designed to verify both the mechanical integrity of cables and supporting hardware under simulated vibration conditions and the optical performance of the cable during specified vibrations. Key features and components of the system include:

- Constant Tension Mechanism: A lever arm with weight increments is used to maintain consistent tension in accordance with IEC 60794-1-21, IEEE 1222, and IEEE 1138 standards.

- Electric Winches: Positioned at both abutments, these winches, in conjunction with a top crane, facilitate the connection of dead-end assemblies, addressing the challenge of handling heavy conductors like OPGW.

- Hydraulic Elevator Platform: Used to lift dead-end assemblies for connection to the lever arm system, simplifying setup for heavy components.

- Free-Position Rail System: Provides flexibility for positioning the shaker, suspension assembly, and abutments to accommodate various test methods and applications.

- Laser Triangulation Sensor: Accurately records vibration amplitude, frequency, and cycle counts during testing.

- Non-Contact Vibration Displacement Sensor: Ensures precise measurement of amplitude, frequency, and cycle counts without physical contact.

- Electro-Mechanical Shaker: Enables variable and precise vibration frequencies with adjustable amplitudes for accurate testing conditions.

This advanced setup ensures comprehensive testing to evaluate cable and hardware performance under real-world vibration conditions.

| Tension Capacity | 20kN (lever arm ratio and dead-weight combination) |

|---|---|

| Accuracy of Tension | 1% |

| Shaker Frequency | 0-40Hz |

| Shaker Stroke | 0-5mm |

| Rail Length | 40m |

Installation Requirements

- Prepare concrete foundations for rail which needs to be prepared by user

- Final solution is subjected to the installation condition, particularly room space, user shall inform us the availability of installation space to generate custom made solution.

- Tension Capacity is customizable per request