Automatic Four Ball Wear Tester

Automatic Four Ball Wear Tester TT-2783Z

Automatic Four Ball Wear Tester TT-2783Z is used to evaluate the Wear Preventive (WP) and Extreme Pressure (EP) characteristics of greases and lubricating oils in sliding steel-on-steel applications.

It adheres to the ASTM D2783, ASTM D2266, and ASTM D4172 Standard Test Methods for Wear Preventive Characteristics of Lubricating Fluid (Four-Ball Method). This tester uses sliding friction under high point contact pressure to assess the carrying capacity of lubricants. It measures three key indices: maximum no-seizure load (PB), sintering load (PD), and composite wear value (ZMZ). Additionally, it is utilized for long-term abrasion resistance tests to measure the friction coefficient.

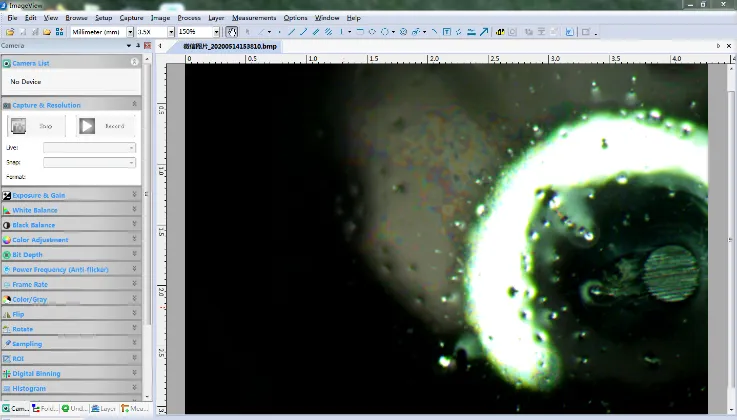

CCD Grinding Measurement System

A. Introduction

The grinding spot measurement system is specifically designed for evaluating the grinding spot produced during friction testing. It is optimized for use with a four-ball friction test machine and comes equipped with all necessary accessories to fully meet the measurement standards required by four-ball testing procedures.

B. Structure and Working Principle of the System

The system consists of measurement software, a microscope, a steel ball holder, a digital camera, a computer, and a standard scale. During operation, the grinding spot on the steel ball is captured by the optical system and projected onto the camera’s CCD sensor. The sensor converts the optical signal into a digital signal, which is then transmitted to the computer via a USB connection. The measurement software reads this data, displays the image on the screen, and enables users to measure and edit the image directly within the interface.

C. Main Parameters

Image sensor (digital camera): 3 million pixels

Image resolution: 1600 × 1200

Measurement range: Up to 4 mm

Measurement accuracy: ±0.01 mm

Microscope model: MDS0754-D, specifically designed for four-ball machines (1 unit)

Base: Model CD-3, includes a high-temperature/room-temperature oil box with a mounted seat (custom oil box seat options available) (1 set)

Workbench: Model SP 1-L, includes a shadowless light source with a 6V / 10W cold anit-halogen tungsten lamp and adjustable brightness

-

Purpose:

Designed to test friction and wear performance of components like end faces and pin plates under sliding friction at room and high temperatures. -

Material Compatibility:

Suitable for testing a wide range of materials, including:-

Metals

-

Engineering plastics

-

Ceramics

-

Powder metallurgy

-

Other advanced materials

-

-

Capabilities:

-

Measures wear resistance and material compatibility

-

Supports testing under various conditions: load, speed, friction pair combinations, and temperature

-

-

Test Force Control:

-

Operated via a hydraulic closed-loop servo system

-

Configured through a computer interface

-

-

Automated Parameter Control:

-

Manages spindle speed, revolutions, test force, friction torque, temperature, and test time

-

Real-time data collection and curve generation

-

Test results can be stored, retrieved, and printed

-

-

Friction Pair Options:

-

Includes 10 different friction pair setups to suit diverse testing needs

-

-

Spindle Drive System:

-

Driven by an AC servo motor with advanced control

-

Offers stepless speed adjustment and consistent torque output

-

High-speed torque accuracy within 0.2%

-

Capable of precise low-speed performance

-

-

Computer & Data System:

-

Embedded computer with industrial control modules

-

Includes dedicated measurement and control software

-

Visual interface with real-time parameter tracking

-

Automatically records and displays key curves, including:

-

Friction coefficient vs. time

-

Temperature vs. time

-

Test force vs. time

-

Speed vs. time

-

-

-

Software Updates:

-

Complimentary updates provided as available

-

| Specification | Value |

|---|---|

| Test force range (stepless adjustable) | 50N~10000N, Error within ±1% |

| Max friction force | 1000N±2% |

| Friction force torque measuring range | 0~15Nm, automatic display the saved value |

| Main spindle speed | 1~3000rpm±1rpm, servo stepless adjustable |

| Temperature control range | Ambient~1000℃±2℃ |

| Test medium | Air, Oil, Water, Mud and Grinding Material etc. |

| Time range | 1s~9999min |

| Stop method | Manual/Automatic (Time, Revolutions, Torque, etc.) |

| Oil chamber stroke | >45mm |

| Main spindle power | 3Kw |

| Dimension | 1200x870x1700mm |

| Weight | 850kg |