Color is a fundamental element that shapes our perceptions and drives the success of countless products and services across diverse industries. The Spectrophotometer for Color Analysis has emerged as the gold standard for achieving unparalleled color precision, empowering organizations to overcome the hurdles of color management and unlock new levels of quality, efficiency, and customer satisfaction.

Whether it’s the vibrant hues of a fashion collection, the precise shades of a premium paint, or the enticing appearance of packaged foods, accurate color measurement and analysis are critical to meeting customer expectations and maintaining a competitive edge.

However, the path to color perfection is often fraught with challenges. Businesses in color-sensitive industries face mounting pressure to ensure consistent, high-quality color throughout their products and processes. Factors such as variable lighting conditions, material differences, and shifting market preferences can all contribute to color inconsistencies that can lead to customer dissatisfaction, product rejections, and costly rework.

Understanding the Fundamentals of Spectrophotometry

At the core of accurate color analysis lies the science of spectrophotometry. To fully harness the power of benchtop spectrophotometers, it’s essential to first understand the fundamental principles that underpin this sophisticated technology.

A. Defining Spectrophotometry and Colorimetry

Spectrophotometry is the measurement of the reflection or transmission properties of materials as a function of wavelength. It is the scientific method used to quantify and analyze the color of an object by measuring its interaction with light. Colorimeters use broadband filters—often two or three—to obtain the tristimulus XYZ values directly (no spectrum for the object is obtained).

Colorimetry, on the other hand, is the branch of science that deals with the measurement and specification of color. Spectrophotometers measure the full visible spectral range to obtain a reflectance spectrum of a sample for a known illuminant, and the tristimulus XYZ values can be calculated by the product of the object’s reflectance values, the spectrum for the illuminant, and the standard observer values.

These two disciplines work hand-in-hand to provide a comprehensive understanding of color characteristics.

B. The Principles of How a Spectrophotometer Measures Color

A spectrophotometer operates by shining a beam of light onto a sample and measuring the amount of light that is reflected or transmitted. The instrument then analyzes the spectral distribution of the reflected or transmitted light, which is unique to the material’s color and composition.

By breaking down the light into its individual wavelengths, the spectrophotometer can precisely determine the color coordinates, such as Lab* or CIE XYZ, that accurately describe the sample’s appearance.

This precise color measurement approach allows spectrophotometers to go beyond the limitations of the human eye, which can only perceive a limited range of colors. By leveraging the power of spectrophotometry, businesses can ensure consistent, quantifiable color across their products, enabling them to meet the stringent demands of today’s color-conscious consumers.

Interpreting Benchtop Spectrophotometer for Color Analysis Data

Once you have the color data from a spectrophotometer, the true power of this technology lies in your ability to properly interpret and utilize the information it provides. Understanding how to read and analyze spectrophotometer results is the key to unlocking the full potential of this advanced color measurement tool.

A. Understanding Spectrophotometer Readings and Data

Spectrophotometers generate a wealth of data, including color coordinates, reflectance curves, and various color difference metrics. Learning how to interpret these readings is essential for making informed decisions about your product’s color performance.

The most common color coordinate systems used in spectrophotometry are Lab* and CIE XYZ. Lab* values provide a comprehensive description of color, with L* representing the lightness or darkness of a sample, a* representing the red-green axis, and b* representing the yellow-blue axis. CIE XYZ values, on the other hand, are the tristimulus values that define a color in the CIE color space.

B. Analyzing Color Strength and Color Differences

In addition to color coordinates, spectrophotometers can also measure and report on color strength and color differences. Color strength is a critical factor in industries such as paints, inks, and textiles, where maintaining the desired intensity of a color is essential. Spectrophotometers can precisely quantify color strength, enabling you to make adjustments to achieve the perfect hue.

Furthermore, spectrophotometers can calculate color differences between a sample and a reference, using metrics such as ΔE (total color difference) and ΔL*, Δa*, and Δb* (individual color component differences).

To obtain L*, a*, and b*, the spectrophotometer measures the diffuse reflectance of the sample, at specific wavelength intervals over the wavelength range of the spectrophotometer (normally, a 10 nm wavelength interval).

The tristimulus color coordinates XYZ, are calculated from the product of the object’s reflectance values, the spectrum for the illuminant, and the standard observer values. L*, a*, and b* can then be calculated from XYZ by the equations:

- L* = 116(Y/Yn)^1/3 – 16

- a* = 500[(X/Xn)^1/3 – (Y/Yn)^1/3]

- b* = 200[(Y/Yn)^1/3 – (Z/Zn)^1/3]

where Xn, Yn, and Zn are the values of X, Y, and Z for the illuminant that was used for the calculation of X, Y, and Z of the sample.

These measurements allow you to identify and address any deviations from your target color, ensuring consistent quality across your products.

C. Utilizing Spectrophotometer Data for Decision-Making

By leveraging the data provided by this instrument such as a spectrophotometer for paint color matching, you can make informed decisions that drive your business forward. From optimizing color formulations and improving quality control to enhancing product development and streamlining supply chain processes, the insights gleaned from spectrophotometer data can be transformative for your organization.

Benchtop Spectrophotometers: The Optimal Choice for Color Analysis

As businesses strive to achieve color perfection in their products and processes, the advantages of Spectrophotometer for Color Analysis become increasingly clear. These sophisticated instruments have emerged as the gold standard for comprehensive color analysis, offering unparalleled precision, versatility, and performance.

A. Advantages of Using a Benchtop Spectrophotometer

Benchtop spectrophotometers boast a range of features that make them the optimal choice for color analysis:

1. Exceptional Accuracy

These instruments are renowned for their highly repeatable and reproducible color measurements, meeting the stringent demands of industries such as paint, textiles, plastics, and beyond.

2. Wider Measurement Range and Greater Color Sensitivity

Benchtop spectrophotometers offer a broader measurement range and enhanced color sensitivity compared to handheld or portable models, enabling the capture of even the most nuanced color variations.

3. Ease of Use and Robust Data Management

Benchtop spectrophotometers are designed with intuitive software interfaces and powerful data management capabilities, streamlining the color analysis process and facilitating informed decision-making.

B. Applications of Benchtop Spectrophotometers in Different Industries

The versatility of benchtop spectrophotometers is truly remarkable, as they find applications in a diverse range of color-sensitive industries:

1. Paint and Coatings

Benchtop spectrophotometers are essential for accurate paint color matching, formulation, and quality control, ensuring consistent hues across batches and products.

2. Textiles and Apparel

Spectrophotometer for textile color matching plays a crucial role in color analysis, enabling brands to achieve precise color matching and maintain color integrity throughout the production process.

3. Plastics and Polymers

Benchtop spectrophotometers are used to measure and analyze the color of plastic materials, which is critical for product development, quality assurance, and color consistency.

4. Printing and Packaging

In the printing and packaging industry, benchtop spectrophotometers are invaluable for color management, ensuring that printed materials and packaging maintain their desired appearance.

5. Food and Beverages

Benchtop spectrophotometers are employed to measure the color of food and beverage products, supporting quality control, product development, and regulatory compliance.

By leveraging the advanced capabilities of benchtop spectrophotometers, businesses in these and other color-dependent industries can achieve unprecedented levels of color perfection, driving customer satisfaction, operational efficiency, and competitive advantage.

Introducing the Benchtop Color Spectrophotometer – Colorimeter from Torontech

Achieving color perfection has become a critical imperative for businesses across diverse industries, from paints and coatings to textiles and packaging. To address this growing need, Torontech, a leading provider of cutting-edge scientific instruments, introduces its exceptional Benchtop Color Spectrophotometer – Colorimeter, designed to revolutionize the way organizations approach color analysis.

The Torontech Benchtop Color Spectrophotometer – Colorimeter, available in models TT-36D, TT-37D, and TT-39D, is a testament to the company’s commitment to innovation and technological excellence. This sophisticated instrument seamlessly combines the precision of spectrophotometry with the versatility of colorimetry, empowering users to unlock new levels of color accuracy and consistency.

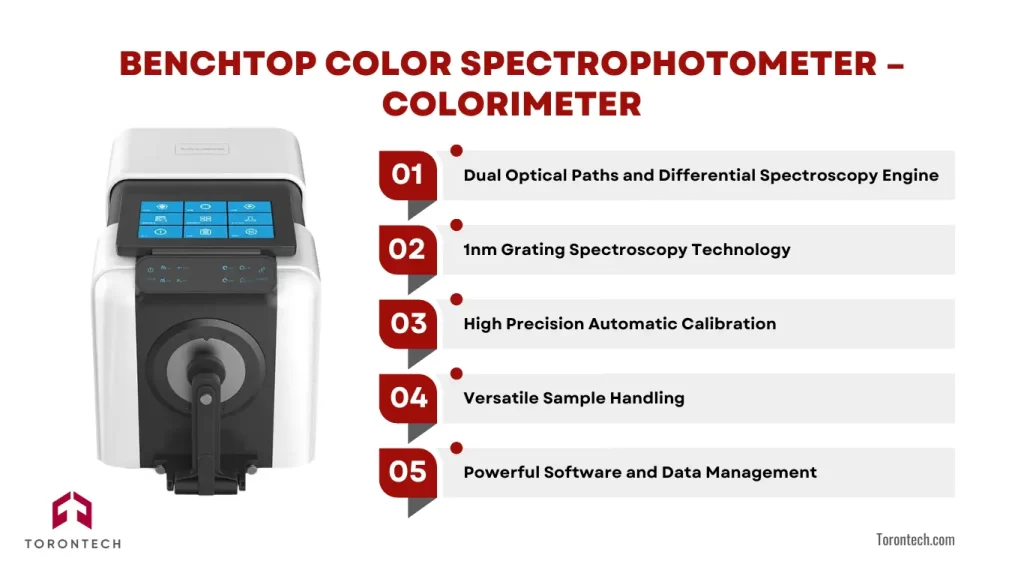

Key Features of the Torontech Spectrophotometer for Color Analysis:

1. Dual Optical Paths and Differential Spectroscopy Engine

Equipped with a dual-path design and a proprietary differential spectroscopy engine, the Torontech Benchtop Color Spectrophotometer – Colorimeter delivers unparalleled repeatability and inter-instrument agreement, with a dEab ≤ 0.005 and dEab ≤ 0.08, respectively.

2. 1nm Grating Spectroscopy Technology

Torontech’s innovative 1nm resolution grating spectroscopy technology enhances color measurement accuracy, setting a new industry standard for color analysis.

3. High Precision Automatic Calibration

Advanced automatic calibration technology and built-in temperature and humidity compensation ensure long-term consistency and reliability, even in varying environmental conditions.

4. Versatile Sample Handling

The instrument’s four interchangeable apertures and support for both reflection and transmission modes allow for the seamless measurement of a wide range of sample types, from solids and powders to liquids and films.

5. Powerful Software and Data Management

The Torontech Benchtop Color Spectrophotometer – Colorimeter comes equipped with the ColorExpert computer software, enabling users to effortlessly manage color data, generate reports, and integrate with color matching applications.

The Torontech Benchtop Color Spectrophotometer – Colorimeter is designed to be the centerpiece of any color-critical operation, providing unparalleled insights and control over color strength, color differences, and overall color performance. Whether you’re working in the paint and coatings industry, the textile and apparel sector, or any other color-sensitive field, this advanced instrument will become an indispensable tool in your arsenal.

By seamlessly integrating spectrophotometry and colorimetry, the Torontech Benchtop Color Spectrophotometer – Colorimeter empowers businesses to achieve new benchmarks in color perfection, ultimately driving customer satisfaction, operational efficiency, and a competitive edge in the market.

Conclusion: Achieving Color Perfection with the Benchtop Color Spectrophotometer

Color is a fundamental element that shapes perceptions and drives the success of countless products and services across diverse industries. The pursuit of color perfection has become a critical imperative, and the Spectrophotometer for Color Analysis has emerged as the gold standard for achieving unparalleled color precision.

The before chapter delved into the importance of color management, the fundamentals of spectrophotometry and colorimetry, and the art of interpreting spectrophotometer data. It highlighted how these advanced instruments empower organizations to overcome the hurdles of color consistency, meet customer expectations, and maintain a competitive edge.

Now, the Torontech Benchtop Color Spectrophotometer – Colorimeter stands as a transformative solution, seamlessly integrating the power of spectrophotometry and colorimetry. This sophisticated instrument is engineered to deliver unparalleled levels of color accuracy and consistency, thanks to its dual optical path design, proprietary differential spectroscopy engine, and innovative 1nm grating spectroscopy technology.

To learn more about the Torontech Benchtop Color Spectrophotometer – Colorimeter, visit our website here and explore our cutting-edge solutions. If you need personalized guidance on your color management needs, contact us now. Our team of experts is ready to assist you.

Reference:

J. Rodgers*, D. Thibobeaux, X. Cui, V. Martin, M. Watson, J. Knowlton. 2008. Instrumental and Operational Impacts on Spectrophotometer Color Measurements. The Journal of Cotton Science 12:287–297