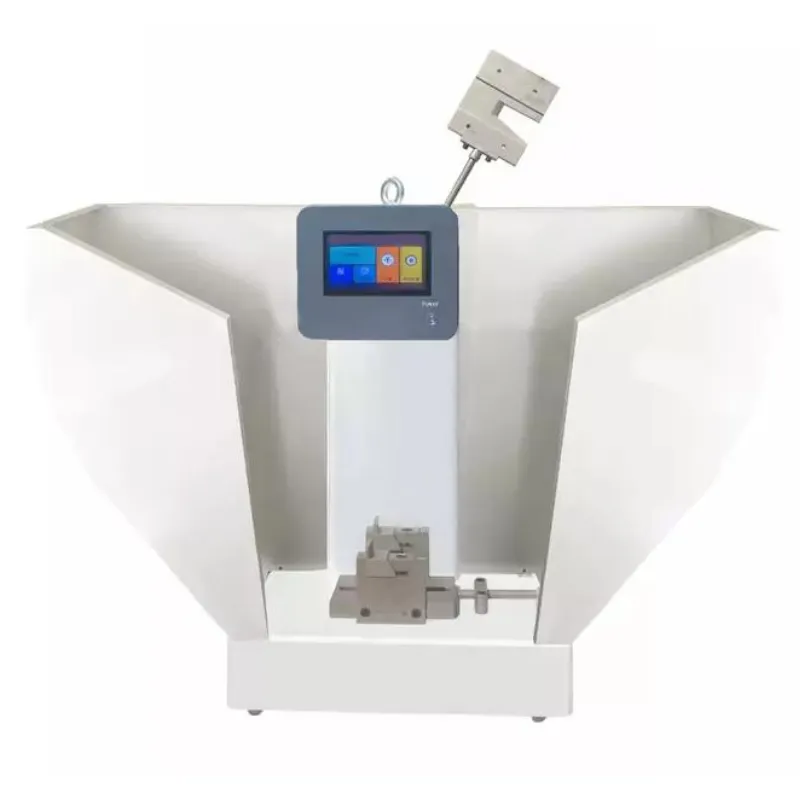

Charpy Impact Tester for Thermoplastic Pipes

Discover precision and reliability with our Charpy Impact Tester for Thermoplastic Pipes. Complying with ISO 9854 standards, this tester accurately measures the impact strength of thermoplastic pipe test pieces used in fluid transport. Equipped with high-precision features such as bearings and a shaftless photoelectric sensor, it eliminates friction-induced losses.

The user-friendly interface and intelligent prompts enhance the testing experience, allowing for the recording of up to 10 test results. This versatile tester generates multiple impact energies with automatic adjustments for air and mechanical friction. Trust in the latest testing standards and ensure accuracy in every measurement with our Charpy Impact Tester for Thermoplastics Pipes.

Charpy Impact Tester for Thermoplastic Pipes

Application

Charpy Impact Tester for Thermoplastic Pipes is utilized to determine the impact strength of test pieces cut from thermoplastic pipes designed for fluid transport.

It is used in scientific research, material testing, or pipe examination.

A brief pipe section or a strip test piece machined from it is conditioned at a specified temperature. Subsequently, it is supported as a horizontal beam, unnotched, and struck once, midway between the supports, by a pendulum possessing a specified impact energy.

Standards

ISO 9854

Charpy Impact Tester for Thermoplastic Pipes Features:

- The Charpy Impact Tester for Thermoplastic Pipes incorporates high-precision bearings and a shaftless photoelectric sensor, fundamentally eliminating friction-induced losses. This design ensures that friction energy loss is significantly lower than the standard requirement.

- The system intelligently prompts the operational conditions based on the impact situation.

- A user-friendly man-machine interaction interface is provided, with clear prompts for each operation. The system can record up to 10 test results.

- It fully complies with the latest testing standards. Energy loss is calculated after 10 swing cycles, with each calibration averaged three times to ensure the accuracy of energy loss.

- One pendulum can generate multiple impact energies.

- Results are automatically adjusted for energy loss attributed to air and mechanical friction.

| Parameter | Value |

|---|---|

| Energy levels | 15J and 50J |

| Span of Charpy | 40 and 70mm |

| Charpy testing impact speed | 3.8m/s |

| Display | Touch screen |