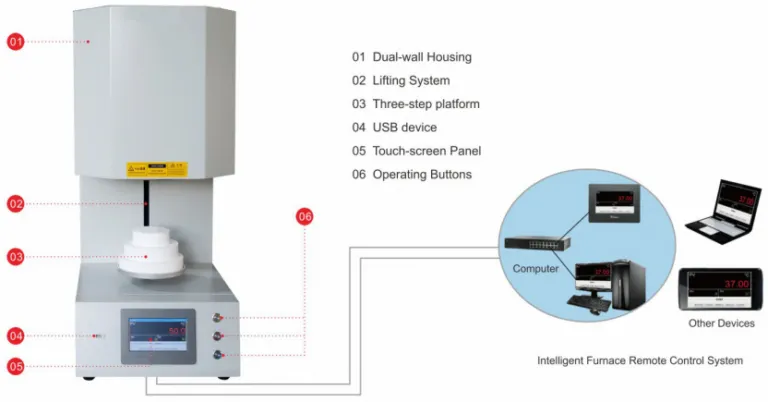

Dental Sintering Lifting Furnace TT-LF-120-1800

Dental Sintering Lifting Furnace TT-LF-120-1800 (also known as a denture crystallization furnace) features high-purity silicon molybdenum rods rated for 1800°C as heating elements, ensuring clean, contaminant-free crystallization and sintering of zirconia dental crowns. It delivers a highly uniform temperature distribution and is designed with a convenient bottom-loading automatic lift system for easy loading and unloading. Ideal for use in dental laboratories and clinics, this furnace is specialized for the sintering and crystallization of zirconia crowns.

Key Features

- Equipped with a 7-inch integrated touchscreen control panel that displays real-time process curves. Data can be exported, and up to 15 sintering programs from different zirconia block brands can be preloaded and accessed as needed. Each program supports up to 30 customizable segments.

- The furnace lining is made from high-purity alumina ceramic fiber, ensuring a clean, contaminant-free environment with iron content ≤440 ppm.

- Uses a pure U-shaped silicon-molybdenum heating rod that prevents contamination during crown processing and supports rapid single-crown firing cycles.

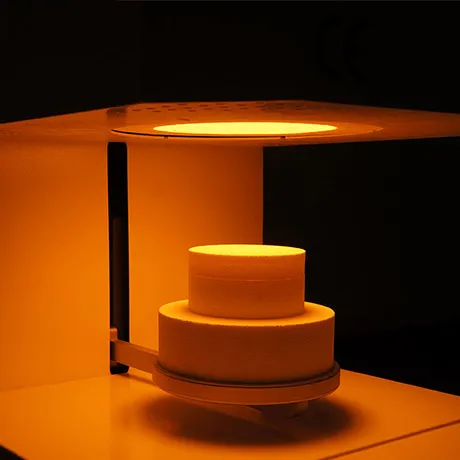

- Features a cylindrical structure with annular heating for a uniform temperature field, delivering excellent consistency and crown density.

- Designed with a bottom-loading mechanism, supported by a precision screw and high-accuracy linear guide for stable, smooth lifting and easy operation.

- Accommodates two φ100mm sintering trays per cycle, allowing for the processing of approximately 25–50 zirconia crowns—ideal for high-volume output.

- Built with a modular safety system that includes visual and audible alarms for over-temperature, overload, and thermocouple failure, along with automatic protective shutdowns.

|

Model |

TT-LF-120-1800 |

|

Chamber Size |

Φ120×120mm |

|

Appreance Size |

400×550×866mm |

|

Weight |

55KG |

|

Max Temp |

1700℃ |

|

Work Temp |

1600℃ |

|

Power/Voltage |

220V/2KW (110V is also available) |

|

Heating Element |

MoSi2 |

|

Chamber Material |

Polycrystalline inorganic alumina ceramic fiber material prepared by wet vacuum filtration |

|

Temp Control Precision |

±1℃ |

|

Thermocouple |

Type B platinum rhodium thermocouple |

|

Temperature Controller |

7-inch intelligent microcomputer PID touch instrument, SCR voltage regulation control, PID parameter self-tuning function; programmable 15 groups of 30 program segments, program heating, program heat preservation, program cooling |

|

Heating Rate |

1-15℃/min freely setting |

|

Body Structure |

Furnace temperature control integrated structure |

|

Protection |

Modular control, sound and light alarm signal will be sent out for over temperature and broken coupler in the working process, and the protection action will be completed automatically |

|

Safety Protection |

The equipment is equipped with a circuit breaker, which will automatically pop open in case of short circuit leakage, which can protect the safety of equipment and operators |

|

Outshell |

High-quality cold-rolled steel plate CNC machine tool blanking processing, after welding, grinding, polishing, phosphating, pickling, surface electrostatic spraying plastic powder |

|

Certificate |

ISO9001 CE SGS TUV |

|

Standard Accessories |

1. Furnace body 1 set 2. Power cord 3 meters 3. Thermocouple 1 piece 4. Manual 1 copy 5. Crucible tongs 1 set 6. One pair of high-temperature gloves 7. Two spare silicon-molybdenum rods |

|

Optional Accessories |

1. Sintering tray 2. Zirconia block 3. Furnace bottom plate |

|

OEM |

Customization of special product specifications can be realized according to user requirements |