Desk Sputter & Carbon Coater - DSCR

The Desk Sputter & Carbon Coater - DSCR is a compact coating system that combines both sputtering and carbon coating capabilities. This versatile system can sputter noble metals like gold (Au), palladium (Pd), platinum (Pt), and gold/palladium (Au/Pd) onto non-conductive or poorly conductive specimens, and it can also apply carbon films to the samples.

The Desk Sputter and Carbon Coater is equipped with a rotary pump and can be configured for DC sputtering and carbon fiber coating (thread) with interchangeable heads, all within one instrument. The DSCR is an adaptable machine designed for preparing samples for scanning electron microscopy (SEM). To enable the observation of non-conductive or poorly conductive specimens using a scanning electron microscope, their surface conductivity needs to be increased during the sample preparation phase before SEM microscopy.

Both sputtering deposition and carbon evaporation are standard methods for sample preparation in electron microscopy. The full automation option makes the system easy to use, even for operators with minimal experience. The user-friendly software with graphical interfaces simplifies the understanding of deposition information, enhancing the overall usability of the system.

The Desk Sputter Coater model DSCR is specifically designed as a sample preparation system for Scanning Electron Microscopy (SEM). It is equipped with a rotary pump that enables the achievement of a vacuum level below 50 mTorr. This vacuum range is well-suited for sputter coating with noble metals and carbon fiber evaporation coating.

For sputtering deposition involving oxidizing metals, Field Emission SEM (FE-SEM), SEM with Energy Dispersive X-ray Spectroscopy (SEM EDX), and applications related to Transmission Electron Microscopy (TEM), we recommend considering other models such as DST1, DSCT, and DCT, which are better suited for these specific purposes.

Pulsed Carbon Fiber Evaporation

The small chamber of the desk vacuum sputter and carbon coater has the capability to perform pulsed carbon fiber evaporation. This method involves using short pulses for more precise and controlled deposition, effectively reducing the amount of debris typically associated with traditional carbon deposition processes.

Carbon Coating Head

The DSCR is equipped with an interchangeable head designed for carbon coating purposes. Its unique capability to load two carbon fibers, each with a diameter of 0.8 mm, enables the deposition of thicker carbon films when necessary or as required for specific applications.

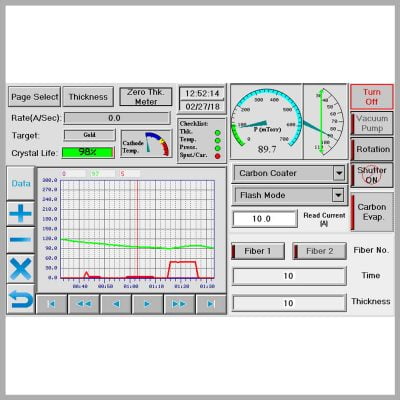

Touch Screen Control with Colorful Display

The DSCR, also known as the Desk SEM Coater, is outfitted with a 7-inch color touchscreen that offers complete automatic control and data input capabilities. This user-friendly interface is designed to be operable even by individuals with limited experience. Users can conveniently monitor vacuum levels, current readings, and deposition information, which can be displayed either as digital data or in graphical curve formats directly on the touchscreen. Additionally, the system has the capacity to store information related to the last 300 coatings, providing easy access through the history page for reference.

Sample Stages

The DSCR offers versatility in sample stage configurations to cater to varying user requirements. These sample stages are designed to be rotatable, with adjustable height settings, and they can be easily interchanged. Notably, the rotary planetary sample stage is an excellent choice for achieving uniform coating, particularly when dealing with porous specimens.