Gelatine Capsule and Soft Gel Hardness Tester – Auto PharmaCheck

A software-driven high precession automatic Gelatine Capsule and Soft Gel Hardness Tester – Auto PharmaCheck designed to measure the hardness and compressive strength of capsules, gelatin materials, and soft or elastic substances.

This device applies a compressive force to the product automatically, following a customizable cycle to evaluate resistance to deformation and adherence to required standards.

Ideal for quality control in the pharmaceutical, cosmetic, food, and related industries, it provides a dependable solution for testing delicate products in compliance with regulatory guidelines.

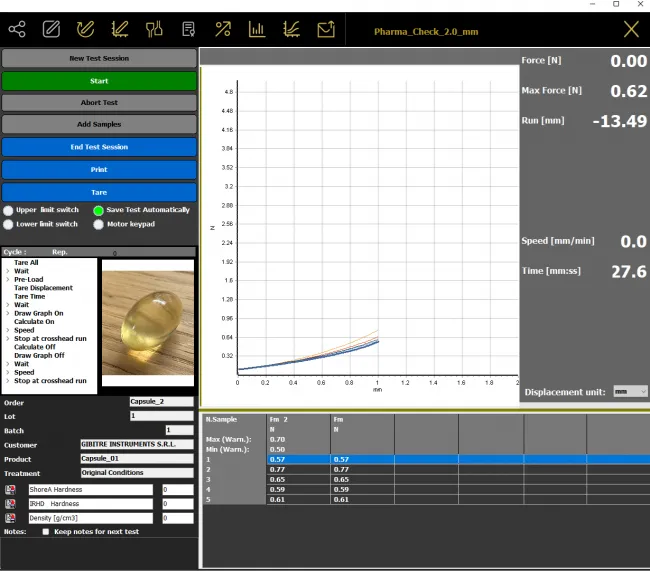

Software

- Software supports predefined test cycles and the creation of customized cycles.

- Provides graphical visualization of force vs. displacement curves.

- Enables product identification via barcode and verifies results against tolerance limits.

- Automatically stores results and curves in SQL databases for easy access and management.

Test Cycle

The instrument enables both standard and customized test cycles to be performed on each capsule.

The standard test cycle applies a 2 mm deformation to the capsule, generates a force application curve, and calculates the maximum force applied during the process.

The software also allows users to create fully customized test cycles, which can include varying deformation levels, maintaining deformation for a specified duration, repeating the cycle a defined number of times, and more.

This versatility makes the instrument ideal for quality control as well as a valuable tool for product development and optimization.

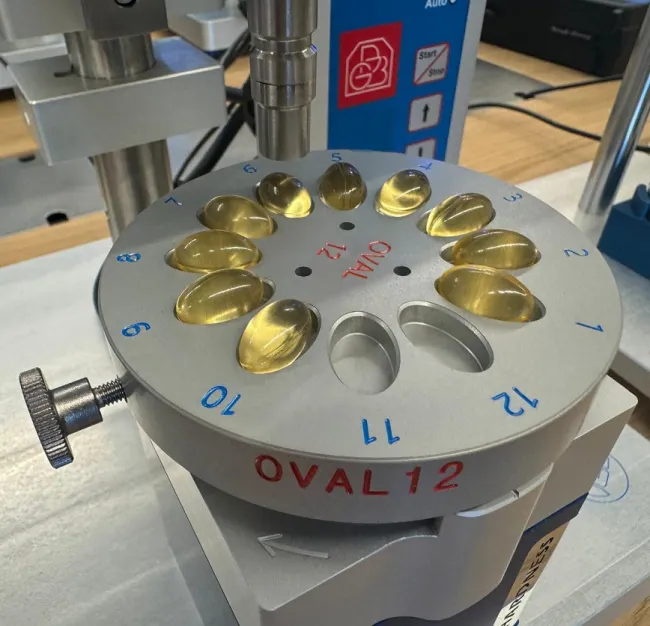

Interchangeable Capsule Holder Plates

The instrument can be equipped with an interchangeable Capsule Holder Plate, enhancing its versatility and automation capabilities.

The Holder Plate attaches above the motorized rotating plate, enabling fully automated testing of all capsules placed in its housing compartments.

Holder Plates are available in various configurations to accommodate different capsule sizes:

- Oval Capsules: Sizes 1, 2, 3, 4, 5, 6, 7.5, 8.5, 10, 12, 16, 20, 30.

- Spherical Capsules: Sizes 1, 2, 4, 5, 6, 7, 9, 15, 20, 28, 40.

- Oblong Capsules: Sizes 3, 4, 6, 8, 9.5, 11, 14, 16, 20, 22, 24.

Custom Capsule Holder Plates with alternative dimensions are available upon request.

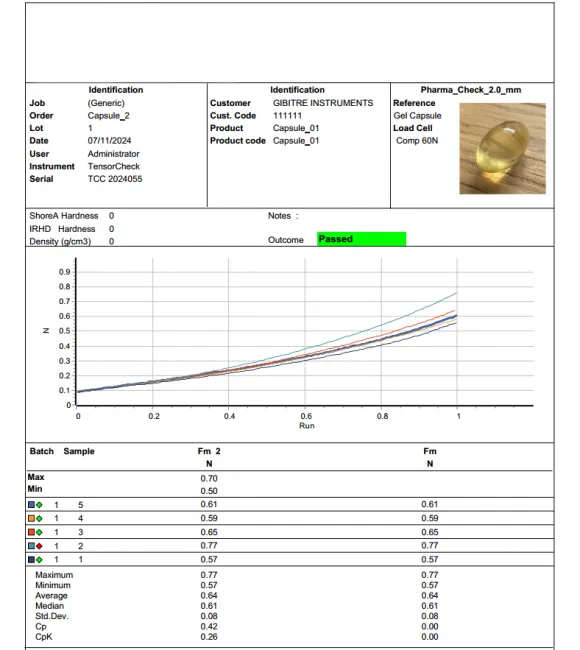

Test report

- The report format is customizable.

- Reports can be edited using the software's built-in editing program.

- The print language is selectable to suit user preferences.

- Reports can be generated automatically at the end of each test.

- Available formats include PDF, Word, and Excel for flexible documentation and sharing.

- Motorized probe displacement mechanism with a precision of 0.0001 mm.

- Load cell capable of measuring applied force, featuring a 60 N full scale and 0.001 N resolution.

- Automated probe plate rotation enabling seamless testing of multiple capsules.

- Digital interface for device operation and real-time force and displacement readings.

| Test Cycle | Customer-defined test cycle with adjustable force-time application |

| Displacement of the Measuring Unit | Motor controlled screw with ball-screw system. Max speed: 85 mm/min. Stroke: 50 mm. Resolution: 0.0001 mm |

| Rotation of the Specimen Holder Plate | Motorised rotation with angle control for automatic execution of multiple tests |

| Load Cell | Max load: 60 N, Resolution: 0.001 N |

| Tool for the Application of the Force | Tool with 10 mm diameter and magnetic attachment |

| Interchangeable Capsule Holder Plates | Plates for Oval, Spherical and Oblong Capsules are available in standard or custom sizes |

Software

| Software | Software for complete instrument control compatible with Windows 11 and saving of results in SQL database |

| Results Storage | Test Results and curves are saved in the SQL database which is installed together with the software |

| Data Analysis | Mean, std. Dev., min, max, Cp, Cpk of test results. X-Chart and Gaussian distribution |

| Software Usage Languages | English and others. |

| Tolerance Verification | Comparison of test results with the tolerance limits set for the product |

| Graphs | The Force-Displacement Curves of the tests performed are displayed in different colours |

| Test Results Calculated for Each Test | Force at Set Displacement, Maximum Force, Displacement at Set Force |