High Vacuum Desk Sputter & Carbon Coater - DSCT

The High Vacuum Desk Sputter & Carbon Coater - DSCT is designed as a versatile instrument that combines both sputter coating and carbon fiber coating capabilities with interchangeable heads. It is well-suited for preparing samples for Scanning Electron Microscope (SEM) analysis.

This high-vacuum coater excels in producing uniform films with fine grain sizes, making it ideal for specimens that demand high-resolution and high-quality characterization, including FE-SEM, EDS/WDS, TEM, and EBSD applications. Equipped with a 2-inch magnetron cathode, an 80 W switching DC power supply, and a high current power supply for carbon evaporation, the DSCT finds utility in various research and thin film applications.

Moreover, the DSCT can be optionally configured with a water-cooled cathode, enhancing its suitability for prolonged sputtering deposition. Additionally, it can be equipped with a higher-power supply to facilitate sputtering of materials like chromium, tungsten, and other oxidizing metal targets.

Hardware:

Automation:

Carbon Evaporation of DSCT

The mini-sized coating system, model DSCT, possesses the capability to create uniform thin films with fine grains on various surfaces through carbon coating. It achieves this using carbon fiber (or alternatively, a carbon rod). The process involves passing an electric current through the carbon fiber, operating in either pulsed or flash mode. This results in the controlled evaporation of carbon, which is then deposited onto the sample. Notably, this method reduces the generation of debris typically associated with traditional carbon deposition processes.

Pulsed Carbon Fiber Evaporation

The small-chamber desk vacuum sputter and carbon coater are equipped to carry out pulsed carbon fiber evaporation. This method employs short pulses, enabling more precise control over the deposition process and resulting in a significant reduction in the generation of debris typically associated with traditional carbon deposition techniques.

Sample Holder Stages

The DSCT offers flexibility in its sample stage configurations, catering to the specific needs of users. The standard sample stage is designed to be rotatable with adjustable height and angle, providing ease of use and versatility. For those requiring uniform coating of porous specimens, an optional rotary planetary sample stage is available and recommended.

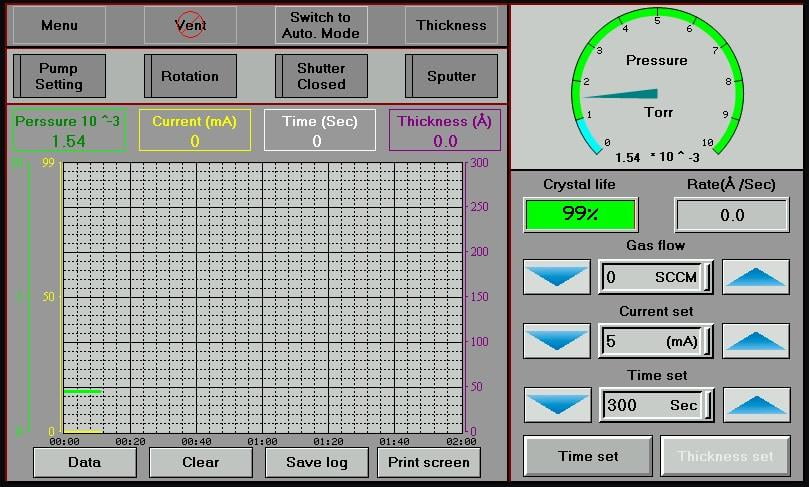

Touch Screen Control with Colorful Display

The DSCT, known as the Desk SEM Coater, features a user-friendly interface with a 7-inch colored touch screen. This interface offers complete automatic control and simplified data input, making it exceptionally easy to operate. Users can monitor crucial parameters like vacuum, current, and deposition, presented as either digital data or graphical curves directly on the touch screen. Moreover, the device stores information from the last 300 coatings in its history log, and this data can be conveniently transferred to a PC using the built-in USB port.