Large Desk Turbo-Pumped Carbon Coater – DCT-300

The Large Desk Turbo-Pumped Carbon Coater – DCT-300 system with a spacious chamber, perfect for prepping samples for FE-SEM, EDS/WDS, TEM, EBSD analysis, and thin film use. This top-notch coater delivers uniform carbon films of exceptional quality, featuring fine grain sizes ideal for specimens needing top-notch resolution and characterization.

The Large Desk Turbo-Pumped Carbon Coater – DCT-300 features a cylindrical chamber with a diameter of 300 mm, enabling extended deposition periods for samples up to 15 cm in diameter or multiple small specimens. Its fully automated programmable carbon coating procedure ensures effortless, accurate, and consistent performance.

Customers have the option to install carbon fiber threads or rods on distinct chamber heads to coat samples using various flash, pulsed, or ramped modes. The ramped mode is exclusively available for carbon rods and can be operated manually or automatically during the deposition process.

The Large Desk Turbo-Pumped Carbon Coater – DCT-300 facilitates fine-grain structural deposition of carbon films, ideal for sample preparation in SEM, FE-SEM, EDX, and TEM applications. Additionally, it enables the creation of conductive layers.

For enhanced hydrophilicity, users have the option to perform TEM grid plasma treatment, though this feature is optional.

Hardware

Automation

Carbon Rod Evaporation (Optional)

The Large Desk Turbo-Pumped Carbon Coater – DCT-300 can be optionally outfitted with a carbon rod head. In this scenario, an external high current power supply ranging from 0 to 100 amperes should be used instead of the internal high current power supply, which is specifically designed for carbon fiber evaporation.

Clean Vacuum

The vacuum chamber of the Large Desk Turbo-Pumped Carbon Coater – DCT-300 is constructed from cylindrical Pyrex. It is equipped with an internally mounted 90 liters per second turbo molecular pump, which can be optionally backed by a 6 cubic meters per hour two-stage rotary vane pump. This setup ensures the introduction of a clean vacuum environment without the oil contamination typically associated with ordinary diffusion pumps.

Touch Screen Control

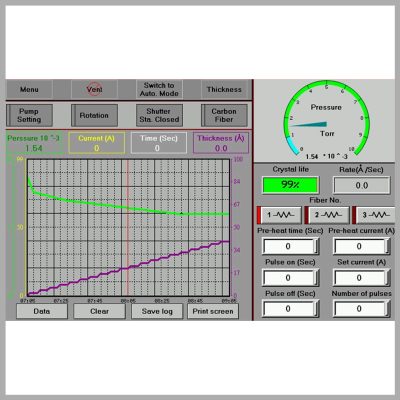

The Large Desk Turbo-Pumped Carbon Coater – DCT-300 comes equipped with a 7-inch colored touch screen, offering full automatic control through user-friendly software to manage and fine-tune the deposition process data. Vacuum and coating sequence details can be viewed either as digital data or plotted curves on the touch screen. The device also stores information on the last 300 coatings, accessible on the history page, and facilitates easy transfer to a PC via a USB port.

Sample Holder Stages of DCT-300

The Large Desk Turbo-Pumped Carbon Coater – DCT-300 offers various sample stage configurations to cater to different user needs. These sample stages are rotatable, adjustable in height and angle, and are easy to swap out.

For uniform coating of porous specimens, users may opt for the optional rotary planetary sample stage.

For deposition on large samples, it is recommended to use the optional 6-inch rotatable sample holder stage. However, please note that this stage does not include angle adjustment.

Standard Sample Holder

Planetary Sample Holder