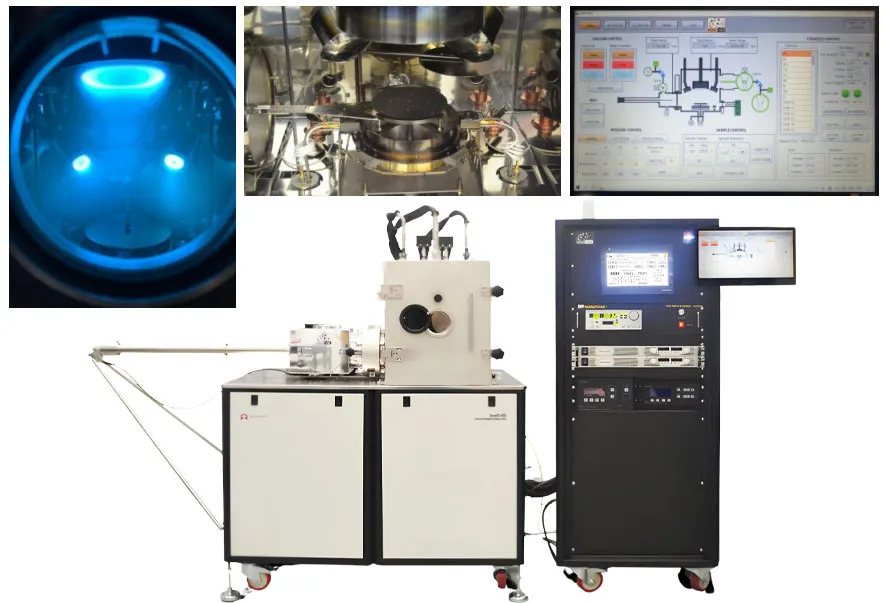

Load-Lock Equipped Coating System

Load-Lock Equipped Coating System ToronTS-450 with Load-Lock chambers offer faster processing and superior coating quality. Sample loading and unloading take place in the Load-Lock chamber, with a magnetic transfer arm moving the sample to the main chamber.

This enhancement is available for Thermal, Sputtering, E-Beam, and HiPIMS systems within our product range. The ToronVak Load-Lock setup enables coating in a high-vacuum environment of 10⁻⁷ Torr while allowing a new wafer to be loaded every 15 minutes.

- Chamber Design: Prismatic/cylindrical vacuum chamber made of SS304 with an electro-polished, feather-touch inner surface and optional water-cooled surfaces.

- Port Configuration: Standard 1", QF, CF, and ISO ports for easy upgrades to additional thermal or sputter sources.

- Observation & Control: UV-blocking observation window, rotatable door shutter, and LabVIEW-programmed sample shutter for precise thickness control.

- Vacuum System: Turbo-molecular, mechanical, and dry pumps with high-speed operation, achieving 10⁻⁸ Torr base pressure in the main chamber.

- Load-Lock Performance: Dedicated pumps reach 10⁻⁶ Torr in 10 minutes, adaptable for sputtering, e-beam, and thermal sources.

- Valves & Isolation: Throttle, vent, isolation, and gate valves ensure the chamber remains under vacuum when idle.

- Automated Control: Fully automatic deposition via software or panel control with real-time LCD displays.

- Cooling System: Automatic closed-loop water cooling with interlock protection to prevent power activation without proper vacuum conditions.

- Sputtering Capabilities: 1”- 6” sputtering guns (RF & DC-driven) with flex heads, self-axis rotation, and compression sealing.

- Material Coating: Coats conductors (Au, Al, Ti, Ni) and insulators (MgO, TiO₂, SiO₂, TiN) at high rates with recipe-based control.

- Vacuum Precision: Adjustable vacuum control from 1000 - 10⁻⁹ Torr using downstream/upstream regulation.

- Sample Heating & Rotation: PID-controlled heating from 50 - 600°C (±1°C sensitivity) and 2 - 30 rpm adjustable rotation, with plasma cleaning (DC/RF).

- Loading Mechanism: Magnetic transfer arm for easy handling of 2”, 3”, 4”, and 6” samples.

- Thickness Measurement: Dual-channel, 0.1 Å/s precision thickness-rate measurement with two QCMs.

- Thermal Sources: 8V - 500A, 4000W thermal sources for sequential and co-evaporation, with a design that minimizes cross-contamination and allows easy source replacement.

- Effusion Cells: 50-800±1°C cells for organic evaporation.

- Gas Mixing & Sputtering: Digital MFC-controlled gas inputs (Ar, N₂, O₂, He, CH₄, etc.) with 0.1 sccm sensitivity for reactive sputtering.

- Efficiency: 1.5-hour experiment cycle, enabling 10-15 experiments per day.

- Warranty: 2-year coverage for materials, design, and craftsmanship.

Please Contact us for pricing, check availability, or ask for additional information about our Load-Lock Equipped Coating System