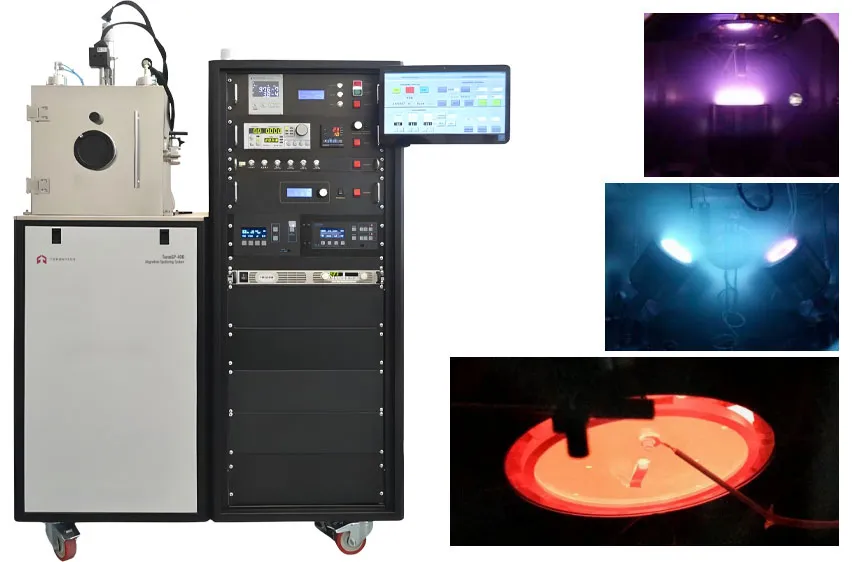

Magnetron Sputtering System

Magnetron Sputtering System ToronSP-400 is a box-type Physical Vapor Deposition (PVD) system designed with prismatic or cylindrical vacuum chambers. It features 1 to 4 DC/RF sputtering sources, allowing the deposition of multi-layered thin films using up to four different materials.

The ToronVak Sputter System can be customized to meet user requirements, enabling the production of multilayered nanoscale metallic, oxide, carbide, or nitride films. Compatible materials include Ni, Fe, Au, Zr, Ti, Si, SiO₂, ZnO, TiO₂, Si₃N₄, SiC, and more.

- Fully Automated Touchscreen Control – Real-time LCD display for seamless operation

- High-Quality Vacuum Chamber – Prismatic or cylindrical SS304 chamber with electro-polished surfaces; available in 30, 40, 50, and 60 cm sizes

- Enhanced Visibility & Access – Front viewing window and rotatable shutter

- Versatile Connectivity – Standard 1", QF, CF, and ISO ports

- Optimized Internal Systems – Built-in lighting and baking system (up to 120°C)

- Power Supply Options – RF: 13.6 MHz, 300-1200 W | DC: 0-1000 V, 2000 W

- High Vacuum Performance – Base pressure: 10⁻⁸ Torr | Achieves 2x10⁻⁶ Torr in 20 minutes

- Advanced Pumping System – Turbomolecular + mechanical pump; cryo and dry pump available

- Wide-Range Vacuum Control – 1000 - 10⁻⁹ Torr precision monitoring

- Customizable Sample Processing – PID-controlled heating (50-700°C) and adjustable sample rotation (2-30 rpm)

- Plasma Cleaning Unit – RF plasma cleaning via RF biasing

- Efficient Cooling System – Automatic start-stop, closed-loop water cooling

- Precision Coating Control – Dual-channel thickness rate measurement (0,1Å/s) with 1-4 QCMs

- Flexible Sputtering Options – 1-4 DC/RF magnetron sputter sources (1”, 2”, 3”, 4”)

- Gas Flow Management – Mass flow meter-controlled inputs (Ar, N₂, O₂, He, CH₄, H₂) with 3-channel real-time control

- Pressure Regulation – Throttle, vent, and isolation valves for precise pressure adjustment (1 - 100 mTorr)

- Optimized Experiment Cycle – 1.5-hour cycle time

- Vacuum Retention – Stays under vacuum with isolation valve when not in use

- Smart PC Control – LabVIEW-based automation for multi-layer coatings

- Additional Precision Monitoring – Capacitance manometer for accurate plasma pressure measurement

- Compact & Mobile Design – 75x120 cm footprint with lockable wheels, fits through standard doors

- Reliable Build – One-year warranty covering design, materials, and craftsmanship

Please Contact us for pricing, check availability, or ask for additional information about our Magnetron Sputtering System