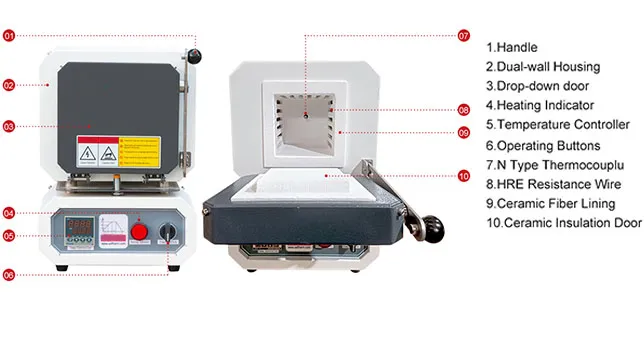

Mini Muffle Furnace TT-MF1000

Mini Muffle Furnace TT-MF1000 is designed for routine laboratory research and testing. It features high-purity alumina for the chamber and a durable alloy resistance wire for the heating element. The advanced temperature control system and premium furnace materials ensure consistent performance and reliable experimental results.

Mini Muffle Furnace TT-MF1000 Features

Furnace Shell

Constructed from Q235 low-carbon steel, the shell features an electrostatic, corrosion-resistant coating.

Its solid metal frame design maintains a low external surface temperature.

The side-opening door with a fixed left hinge allows for smooth, user-friendly operation.

Refractory Structure

Engineered with a multi-layer thermal insulation system, including a double-layer lining of lightweight refractory bricks. The bricks are precisely stacked and fitted for durability—free from asbestos, offering minimal heat loss and improved energy efficiency.

Heating System

Equipped with high-quality HRE spiral resistance wire, wound around ceramic support tubes for free heat radiation inside the chamber. This design delivers energy-efficient, uniform heating and extended service life.

Heating elements are located on three sides—left, right, and bottom—for even temperature distribution.

The silicon carbide base plate shields the bottom heating elements while offering strong thermal conductivity and structural support.

Temperature Control Panel

Features PID control integrated with SCR for precise temperature regulation.

Uses an internationally standardized N-type nickel-chromium-silicon thermocouple with a temperature range of 0–900 °C and long operational life.

Includes a door safety switch that cuts power when the door is opened.

Program Controller

Advanced controller supports complex thermal processes.

User-friendly interface with flexible programming options.

Allows up to 30 programmable segments per temperature curve.

Includes over-temperature and fault alarms, along with automatic safety shutdown.

Optional features include manual air intake, automatic exhaust lid, and a rapid cooling unit capable of cooling the furnace from high temperatures to 400 °C quickly and safely.

|

Model |

TT-MF-1-10 |

TT-MF-3-12 |

TT-MF-6-12 |

TT-MF-8-12 |

TT-MF-12-12 |

TT-MF-18-12 |

TT-MF-30-12 |

|

Chamber size(W xD xH)mm |

100 x100x100 |

150 x150x150 |

180x230x150 |

200x300x120 |

200 x300x200 |

250 x300x250 |

300 x500x200 |

|

Outer size(W xD xH)mm |

250 x240x350 |

430x465x620 |

460x570x660 |

480 x630x630 |

480 x630x710 |

550x635x780 |

600 x870x735 |

|

Max temperature |

1200℃ |

||||||

|

Working temperature |

1100℃ |

||||||

|

Voltage |

220V/1.2KW |

220V/2.5KW |

220V/3KW |

220V/3KW |

220V/4KW |

220V/6KW |

380V/7.5KW |

|

Heating element |

HRE Alloy resistance wire |

||||||

|

Chamber material |

Polycrystalline inorganic alumina ceramic fiber material prepared by wet vacuum filtration |

||||||

|

Temp.Precision |

±1℃ |

||||||

|

Termocouple |

N Type termocouple |

||||||

|

Temperature controller |

Intelligent microcomputer PID temperature control instrument, SSR control, PID parameter self-tuning function; programmable 30 program segments, program temperature rise, program heat preservation, program cooling |

||||||

|

Heating rate |

1-25℃/min free adjustment |

||||||

|

Furnace structure |

Furnace temperature control integrated structure |

||||||

|

Equipment protection |

Modular control, sound and light alarm signal will be sent out for over temperature and broken coupler in the working process, and the protection action will be completed automatically |

||||||

|

Safety protection |

The equipment is equipped with a circuit breaker, which will automatically pop open in case of short circuit leakage, which can protect the safety of equipment and operators |

||||||

|

Furnace shell |

High-quality cold-rolled steel plate CNC machine tool blanking processing, after welding, grinding, polishing, phosphating, pickling, surface electrostatic spraying plastic powder |

||||||

|

Quality certificate |

ISO9001 CE SGS TUV (By Request) |

||||||

|

Standard packing |

1. Furnace body 1 set 2. Temperature controller 1 set 3. Power cord 3 meters 4. Thermocouple 1 set 5. Manual 1 copy 6. Crucible pliers 1 set 7. High temperature gloves 1 pair |

||||||

|

Optional |

1. Optional exhaust chimney for evacuation of volatile substances 2. Optional corundum crucible, furnace floor, shed board and other kiln furniture 3. Optional material recorder for online recording of temperature curves |

||||||