Universal Testing Machines (UTMs) for PC Strand Testing

ASTM E416, ISO 6934, EN 10138

Torontech offers a specialized range of Universal Testing Machines (UTMs) designed specifically for the tensile testing of Prestressed Concrete (PC) Strands, available in 600 kN, 1,000 kN, and 3,000 kN capacities. These high-performance testing systems are engineered to ensure accurate and repeatable results in accordance with international standards for prestressing steel, making them ideal for manufacturers, construction labs, and infrastructure testing centers.

Purpose-Built for PC Strand Testing

Our PC Strand UTMs are optimized for testing uncoated 7-wire strands, single prestressing wires, and high-strength steel cables used in bridges, buildings, and concrete structures. Whether you’re conducting routine quality checks or performing advanced R&D, Torontech’s machines deliver the power, control, and precision you need.

Standards Compliance

Torontech’s PC Strand Testing Machines meet and exceed the following standards:

- ASTM A416 – Standard Specification for Steel Strand, Uncoated Seven-Wire for Prestressed Concrete

- ISO 6934 – Steel for the Prestressing of Concrete

- EN 10138 – Prestressing Steel – Strand

- GB/T 5224 – Steel Strand for Prestressed Concrete

Available Models & Load Capacities

| Model | Load Capacity | Application |

|---|---|---|

| ToronUTM-PC600 | 600 kN | Ideal for standard 7-wire PC strands and wires |

| ToronUTM-PC1000 | 1,000 kN | Suitable for high-strength and oversized PC strands |

| ToronUTM-PC3000 | 3,000 kN | Designed for industrial-scale testing of heavy prestressing cables and assemblies |

Smart Control & Software Integration

- Torontech’s proprietary material testing software with real-time monitoring of force-elongation, stress-strain, and yield curves

- Automated reporting of key parameters: maximum load, yield strength, elongation at break, modulus of elasticity

- Data export in Excel, PDF, CSV, and integration with LIMS

- Customizable test protocols and multi-language support

Applications

- Tensile testing of PC strands for bridges, buildings, precast concrete, and marine structures

- Material certification for construction steel products

- R&D for prestressed concrete technologies

- Quality assurance in steel production and civil engineering labs

Why Choose Torontech’s PC Strand Testing UTMs?

- Wide range of capacities: 600 kN, 1,000 kN, and 3,000 kN

- Full compliance with global standards (ASTM, ISO, EN, GB/T)

- Trusted by civil engineering firms, testing labs, and steel manufacturers worldwide

- Backed by Torontech’s exceptional technical support, training, and after-sales service

Contact Torontech today to request a quote or technical consultation. Our team will help you choose the right model and configuration to meet your testing requirements.

Key Features

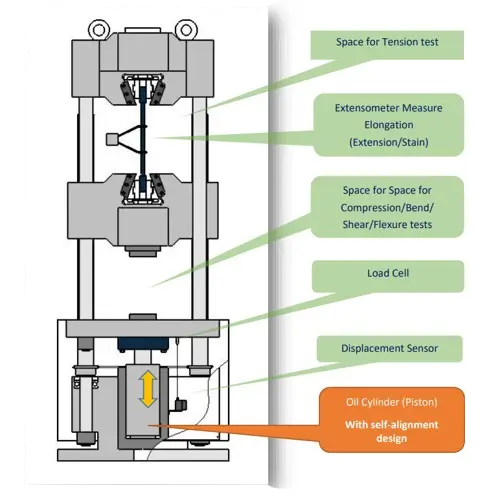

- Heavy-duty hydraulic wedge grips designed to handle high-strength strands without slippage

- Servo-hydraulic control system with closed-loop feedback for precise loading

- Long-travel extensometers or built-in strain measurement systems for accurate elongation monitoring

- Advanced structural frame with minimal deflection for superior test accuracy

- Integrated safety enclosures for operator protection during high-force tests