Aviation Fuel Testing Equipment - Pensky Martens Closed Cup Flash Point Tester – Automatic Model ToronCCFPT-Auto

Pensky Martens Closed Cup Flash Point Tester – Automatic Model ToronCCFPT-Auto

Pensky Martens Closed Cup Flash Point Tester – Automatic Model ToronCCFPT-Auto is a precision instrument designed to determine the lowest temperature at which a liquid’s vapor ignites in air under controlled conditions. This test is essential for evaluating the fire risk of liquid products in industries such as petrochemicals, coatings, inks, and organic solvents. It plays a critical role in quality control and safety testing.

Engineered to meet ASTM D93 standards, the Pensky-Martens Closed Cup Flash Point Tester offers advanced automation. Key features include automatic lid operation, sample lifting, temperature regulation, ignition, measurement, data printing, open-flame detection with extinguishing, intelligent flame stabilization, and rapid cooling.

Working principle

Heating Process:

A precise amount of liquid sample is injected into the standard sealed cup of the flash point tester. The heating system then applies a uniform heating rate to ensure consistent testing conditions and accurate results.

Vapor Formation and Accumulation:

As the sample heats up, it begins to evaporate, creating a combustible vapor-air mixture within the sealed cup. Since the cup is enclosed, the vapor remains contained and gradually builds up.

Flash Point Detection:

When the vapor concentration reaches a critical level, the ignition device generates an electric spark at a specific frequency and location inside the sealed cup. If ignition occurs, the temperature recorded by the sensor is the closed flash point. The tester uses optical and pressure sensors to detect the flash event—optical sensors capture the light produced during ignition, while pressure sensors monitor changes inside the sealed cup.

Applicable Standards

ASTM D93, established by the American Society for Testing and Materials (ASTM), is a widely recognized testing method for determining the flash point of petroleum products and other flammable liquids using a sealed cup tester. The flash point is the lowest temperature at which a liquid generates enough vapor to form a combustible mixture with air and ignite when exposed to a flame. This standard is essential in industries such as petrochemicals, transportation, and safety regulation worldwide.

Application Areas

-

Petroleum Refining and Chemical Industry: Used to test the flash point of crude oil, fuels (gasoline, diesel, lubricants), and petrochemical intermediates. Ensures compliance with quality standards and provides critical data for safe storage, handling, and transportation.

-

Quality Testing and Certification Agencies: A key tool for verifying the safety and quality of liquid products. Agencies conduct flash point tests according to industry standards, issue certified test reports, and help ensure regulatory compliance in the market.

- 8-Inch HD Touchscreen: Equipped with a high-resolution LCD touchscreen and an intuitive English-language interface.

- Customizable Testing Parameters: Allows presetting of temperature, sample name, and delayed temperature. Users can adjust heating rate, stirring speed, ignition frequency, and pre-ignition temperature.

- Real-Time Monitoring: Accurately simulates and tracks temperature and test duration, with built-in prompts to guide users and prevent errors.

- Automatic Pressure Calibration: Integrated atmospheric pressure sensor automatically adjusts for pressure variations to ensure precise results.

- Fast Mode Option: Enables quick estimation for unknown samples.

- Dual Ignition Methods: Switch between electric and gas ignition for flexible operation.

- Automated Lifting Arm: Fully automatic system for lifting, opening, detecting, and printing data.

- Rapid Cooling System: Cools the heating system within 10 minutes, allowing for faster test cycles.

- Intelligent Sample Cup Cooling: Automatically starts and stops cooling based on sample cup temperature.

- Automatic Silicon Nitride Ignition: Eliminates the need for manual ignition tools.

- Flame Detection & Automatic Ignition: Ensures stable operation while extending the lifespan of the ignition system.

- Advanced Fire Safety System: Hidden dual fire extinguishing heads detect open flames and release inert gas to extinguish within two seconds.

- LIMS Connectivity: Connects to Laboratory Information Management Systems via USB for seamless data integration.

| Voltage | AC220V ± 10% 50Hz ± 10% (110V is also available) |

| Environmental temperature | 10-40 ℃ |

| Relative humidity | < 80%RH |

| Other | There is no strong vibration, airflow, strong electromagnetic interference, or corrosive gas around the laboratory. |

Technical Specifications

| Measurement range | Room temperature to 400 ℃ |

| Repeatability | ≤ 2 ℃ |

| Reproducibility | ≤ 4 ℃ |

| Resolution | 0.1 ℃ |

| Heating rate | Step A: (5-6) ℃/min |

| Step B: (1-1.5) ℃/min | |

| Step C: (2.5-3.5) ℃/min | |

| Quick mode: (10-15) ℃/min | |

| Custom mode: Adjustable heating rate | |

| Sample cup cooling | Intelligent air cooling |

| Fire extinguishing method | Inert gas spraying for fire extinguishing |

| Furnace cooling | Forced air cooling |

| Ignition method | Electric ignition, gas ignition can be freely switched |

| Flame holding | Intelligent detection, automatic ignition. |

| Power consumption of the whole machine | ≤ 300W |

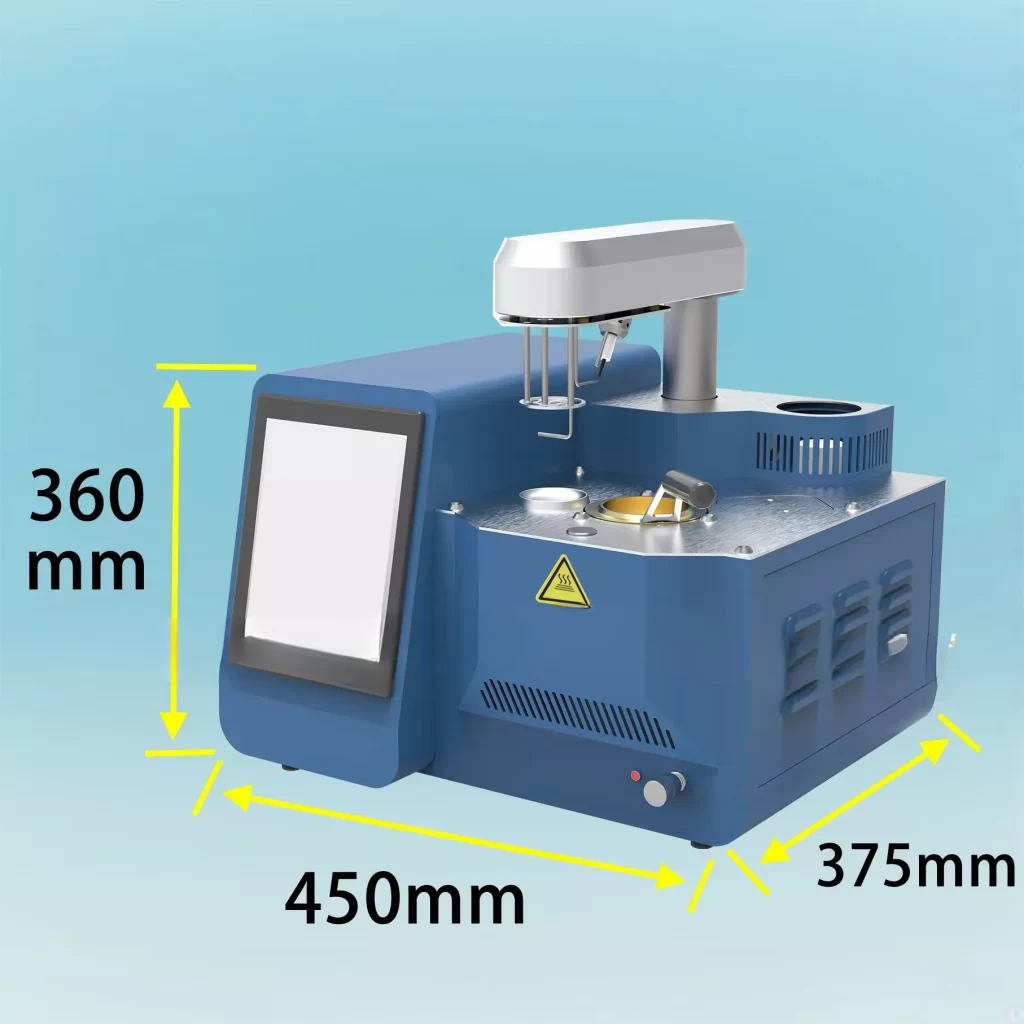

| Main unit diemensions | 450 × 375 × 360 (mm) |

Standard Configuration List

| Number | Product Name | Specification | Unit | Quantity |

| 1 | Automatic Closed Cup Flash Point Tester | ToronCCFPT-Auto | Unit | 1 |

| 2 | Oil cup | Piece | 2 | |

| 3 | Power cord | 10A | Piece | 1 |

| 4 | Ignition gun | Piece | 1 | |

| 5 | Clamp | Φ 12mm | Piece | 2 |

| 6 | PU tube | 6mm | Meter | 5 |

| 7 | PU tube | 8mm | Meter | 0.3 |

| 8 | Variable diameter joint | 8mm to 6mm | Piece | 1 |