Industrial Furnace – TT-IF-100-1200A

TT-IF-100-1200A is a 1200°C manual-door industrial furnace designed for heat treatment processes such as quenching, tempering, normalizing, and annealing of metal materials. It is also well-suited for sintering non-metallic ceramic materials. Ideal for small-batch production and pilot testing in labs and industrial settings.

| Model No. | TT-IF-100-1200A |

| Chamber Size | 450x500x600MM |

| Continuous Temperature | 1100℃ |

| Max Temperature | 1200°C |

| Voltage | 380V |

| Heating Element | High Quality HRE |

| Temperature Precision | ±1°C |

| Thermocouple | N type |

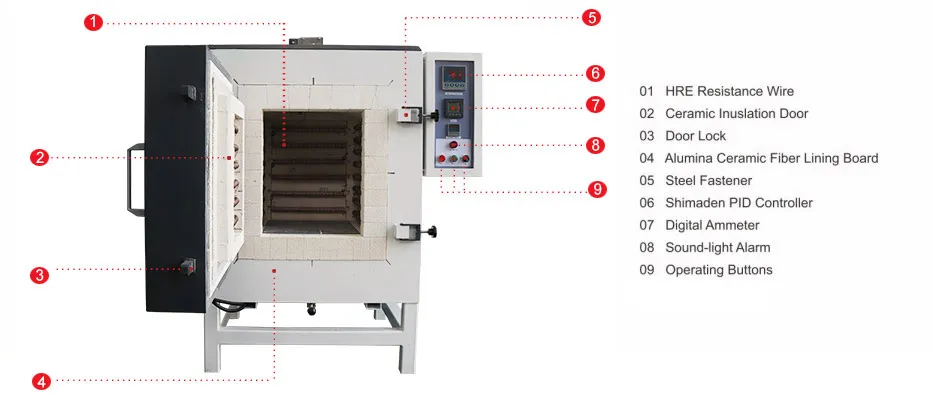

Industrial Furnace – TT-IF-100-1200A Features

Furnace Shell

- The shell is constructed from Q235 low-carbon steel with an electrostatically resistant, corrosion-protected surface.

- Its sturdy metal frame ensures structural integrity while maintaining a low exterior temperature.

- The furnace features a side-opening door with a fixed left hinge for convenient operation.

Refractory Lining

- The furnace uses a multi-layer insulation system with a double layer of lightweight refractory bricks. This design provides a robust structure, efficient thermal retention, and low energy consumption—free of asbestos.

Heating System

- High-grade HRE spiral resistance wire elements are mounted on ceramic support tubes, delivering efficient, radiant heat throughout the chamber for extended performance.

- Heating is distributed on three sides—left, right, and bottom—to ensure consistent temperature uniformity.

- A silicon carbide base plate shields the bottom heating element, offering strong mechanical durability, excellent thermal conductivity, and stable horizontal load support.

Temperature Control Panel

- PID control with SCR output delivers precise temperature management.

- Equipped with an international-standard N-type nickel-chromium-silicon thermocouple, supporting a temperature range of 0–1300°C and ensuring long-term reliability.

- Safety power cutoff activates automatically when the furnace door is opened.

Program Controller

- Advanced controller supports a wide range of process requirements.

- User-friendly interface allows flexible, intuitive programming.

- Stores up to 30 programmable segments for a single heating curve.

- Built-in over-temperature and fault alarms with automatic safety shutoff.

- Optional features include manual air intake and automated clamshell exhaust.

- An optional rapid cooling unit enables controlled air cooling of the chamber to below 400°C.

|

Model |

TT-IF-45-1200 |

TT-IF-64-1200 |

TT-IF-80-1200 |

TT-IF-96-1200 |

TT-IF-100-1200 |

TT-IF-150-1200 |

TT-IF-200-1200 |

|

Chamber Size (W xD xH)mm |

300 x500x300 |

400 x400x400 |

400x500x400 |

400x600x400 |

400 x530x460 |

450 x530x590 |

500 x530x720 |

|

Rated Temperature |

1200℃ |

||||||

|

Work Temperature |

1100℃ |

||||||

|

Voltage |

380V/12KW |

380V/15KW |

380V/16KW |

380V/18KW |

380V/18KW |

380V/24KW |

380V/27KW |

|

Heating Element |

HRE Alloy Resistance Wire |

||||||

|

Chamber Materials |

Polycrystalline inorganic alumina ceramic fiber material prepared made by wet vacuum filtration |

||||||

|

Temp control Accracy |

±1℃ |

||||||

|

Thermcouple |

N Type Thermcouple |

||||||

|

Temperature Controller |

Intelligent microcomputer PID temperature control instrument, SCR/SSR control, PID parameter self-tuning function .Programmable 30 segments for program heating, program heat preservation, program cooling |

||||||

|

Heating Rate |

1-15℃/min can be adjustable |

||||||

|

Furnace Structure |

Furnace temperature control integrated structure |

||||||

|

Equipment Protection |

Modular control with sound and light alarm signal sending out for over temperature and thermocouple broken in the working process, and the protection action will be completed automatically |

||||||

|

Safety Protection |

The equipment is equipped with a circuit breaker, which will automatically pop open in case of short circuit leakage, which can protect the safety of equipment and operators |

||||||

|

Furnace Shell |

High-quality cold-rolled steel plate with CNC machine tool processing, then it will have the process of welding, grinding, polishing, phosphating, pickling, surface electrostatic spraying plastic powder |

||||||

|

Quality Certificate |

ISO9001 CE SGS TUV |

||||||

|

Standard Device |

1、Furnace Main Body : 1 set 2、Temperature Controller : 1 pc 3、Power Line : 3 meters 4、Thermcouple : 1 pc 5、Operation manual ; 1 pc 6 Crucible Tong ; 1 pc 7、High Temperature Gloves : 1 pair |

||||||