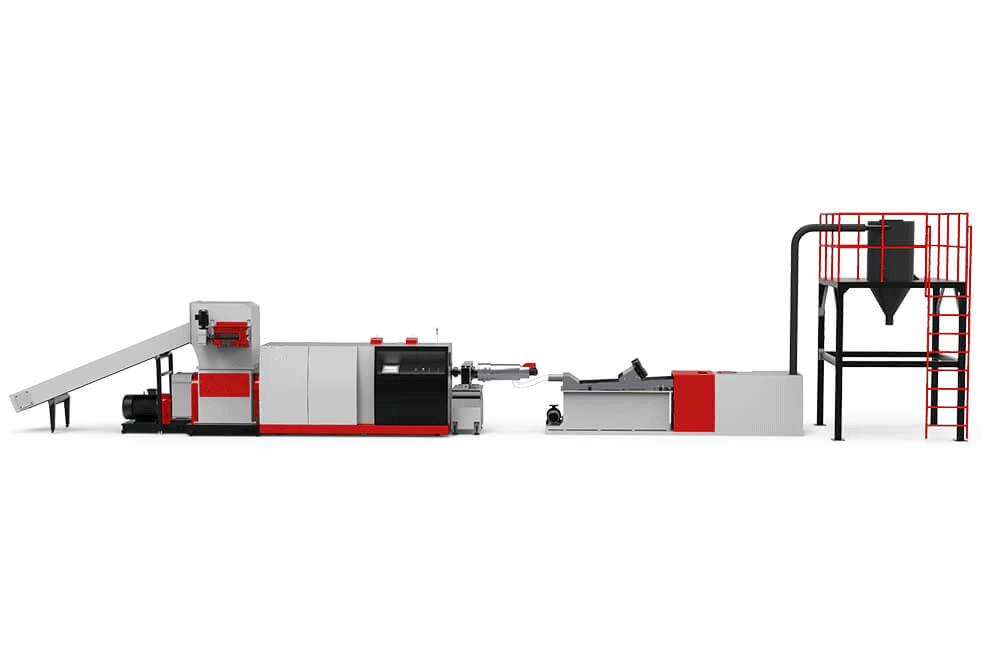

Shredder Extruder Recycling Pelletizing System - Single Screw Extrusion Line for Shredding and Pelletizing

Single Screw Extrusion Line for Shredding and Pelletizing

The Single Screw Extrusion Line for Shredding and Pelletizing system integrates shredding, crushing, enforced feeding, plasticization, and pelletizing into a single process. This Single Screw Extrusion Line for Shredding and Pelletizing system is utilized in plastic recycling and pelletizing, offering an integrated and cost-effective solution for various types of plastic scrap, including film, raffia, trim, purge, hollow parts, bottles, and foaming materials in plant recycling.

SHREDDING/ENFORCING FEEDING

In partnership with a European shredder supplier, we've developed specialized shredding rotor sets that combine with single-screw extruders. This setup is designed to pre-reduce, crush, and enforce feed various types of plastic scraps. These scraps can be in the form of film, bottles, raffia, woven bags, non-woven fabrics, purges, or lumps. It's a versatile system capable of handling all kinds of plastic scrap, regardless of their condition.

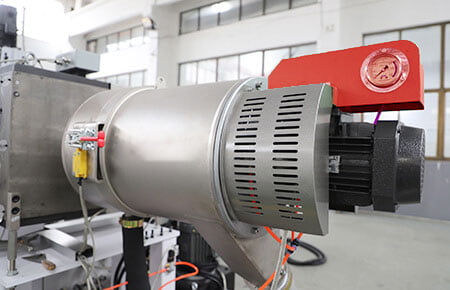

PLASTICIZATION AND DEGASSING

A specialized single-screw extruder is used to gently melt the crushed plastic scraps. These scraps are melted and plasticized within a 32D processing section. With a double-zone vacuum degassing system, volatiles like moisture and low-molecular substances are efficiently removed. This system is particularly well-suited for re-pelletizing heavy printed and moisture-sensitive plastic scraps.

INTELLIGENT CONTROL

Intelligent Start: Initiate the entire process with a single button. The interconnected system modules will follow the set logistical sequence and materials processing requirements seamlessly.

Intelligent Stop: Cease operations across all related modular parts in the ACS system using a single button.

Emergency Stop: The ACS system features an emergency stop function to halt operations immediately in case of any unforeseen risks during machine operation.

REMOTE MONITORING AND INFORMATION TRANSMISSION

The ACS system incorporates a remote monitoring and transmission system. It offers Bluetooth connectivity, enabling remote monitoring and seamless information transmission functionalities.

NONE-STOP PISTON TYPE FILTER

* You can opt for either a regular single-plate/piston double-station screen changer or a non-stop double plate/piston four-station at the extruder head to achieve significant filtration performance.

* Longer screen lifespan and reduced screen change frequency: The extensive filter areas result in a longer filter lifetime.

* User-friendly and continuous operation: Facilitates easy and rapid screen changes without halting the machine.

* Extremely low operational costs.

PLATE TYPE FILTER

The Plate type filter is designed as a continuous system with two filter plates. At least one filter remains operational during screen changes. Additionally, it features a ring-shaped heater for consistent and stable heating.

SELF CLEAN FILTER

This model integrates our in-house developed self-cleaning filter, the new SCF self-cleaning filtration system. This system enables continuous recycling extrusion, particularly ideal for re-pelletizing highly contaminated materials. The SCF filtration system effectively manages and eliminates up to 5% of contaminants in the molten flow, separating materials such as paper, wood, aluminum, unmelted plastic, and rubbers, among others.

WATER RING PELLETIZING SYSTEM

* Self-adjusting pelletizing head ensures optimal granulate quality and extended uptime by maintaining consistently correct blade pressure.

* Rotatory blade RPM adjusts automatically based on melt extruding pressure.

* Effortless and rapid pelletizer blade changeovers, saving time without the need for adjustment work.

UNDER-WATER PELLETIZING SYSTEM

A highly automated pelletizing system ideal for materials with high MFI and demanding production capacities. This comprehensive system comprises a pelletizer, valve, conveying pipeline, dewatering vibrating screen, and silo.

VIBRATION DRY

* The advanced dewatering vibration sieve, combined with horizontal-type centrifugal dewatering, delivers highly effective drying for pellets while minimizing energy consumption.

* Assembled sieves: Installed and secured by screws rather than welding, allowing for easy future sieve changes.

PLASTIC PARTICLES

Final output: plastic particles. The plastic pellets can be reused to produce high-quality plastic products once again.

PACKING SYSTEM

* Final qualified granules are stored here. The drying shaker, combined with the horizontal centrifuge, achieves efficient drying with lower energy consumption.

* Capacity online monitoring & Quantitative weighing system.