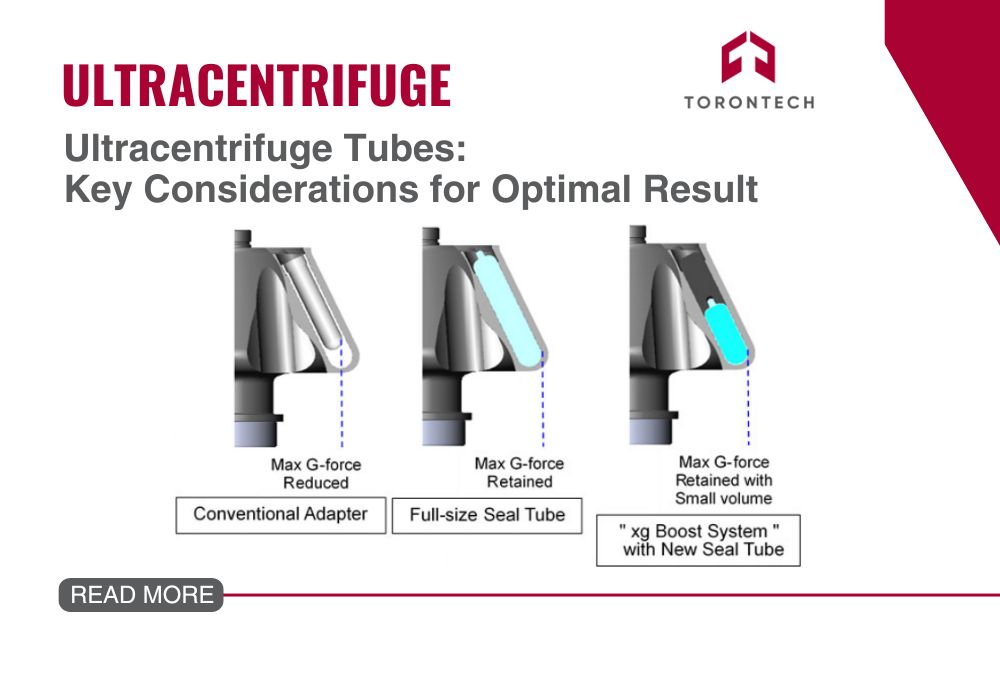

Choosing the right ultracentrifuge tubes is key to achieving accurate and consistent results in your lab. These tubes do more than just hold samples; they need to withstand extreme g-forces, resist chemicals, and fit seamlessly into your ultracentrifuge. When selecting tubes, consider factors like material, size, and compatibility with your specific rotor.

Making informed decisions about ultracentrifuge tubes ensures that your samples are processed safely and efficiently. Whether you’re working with small volumes or accommodating large volumes in especially swing bucket rotors, understanding these considerations can greatly improve your centrifugation outcomes. Ready to optimize your lab work? Let’s dive into the key factors that make the difference.

Consider Material Selection When Choose Ultracentrifuge Tubes

Selecting the right material for your ultracentrifuge tubes is crucial to achieving reliable results. These tubes are available in various materials, each offering unique benefits depending on your specific application.

1. Polyethylene Terephthalate (PET)

PET tubes are known for their optical clarity, allowing you to easily monitor samples during centrifugation. They provide decent chemical resistance and are suitable for many standard lab applications. However, PET may not handle the highest g-forces as well as other materials.

2. Polycarbonate (PC)

PC is another popular choice, valued for its durability and heat resistance. PC ultracentrifuge tubes can withstand higher g-forces compared to PET, making them ideal for high-speed centrifugation. These tubes offer moderate chemical resistance, suitable for most solvents used in biological and chemical labs.

3. Chemical Resistant Stainless-Steel

For the most demanding applications, chemical resistant stainless-steel tubes are the go-to option. These tubes can endure harsh chemicals and extremely high g-forces without compromising integrity. Although they are not transparent, their robustness makes them indispensable when working with aggressive solvents or under extreme conditions.

4. Special Caps for Fixed-Angle Rotors

When using ultracentrifuge tubes in fixed-angle rotors, it’s essential to consider the caps. Special caps are designed to provide added resistance to g-force, ensuring that your samples remain secure even under intense centrifugation. This feature is especially important when working with high-speed protocols where stability is crucial.

5. Material Considerations Based on Volume

The material choice also depends on the volume of samples you’re working with. For smaller volumes, such as 1 ml ultracentrifuge tubes, PC or PET materials are often sufficient. Larger volumes, however, might require more durable materials like stainless steel to ensure safety and efficiency during centrifugation.

6. Balancing Performance and Cost

While chemical resistant stainless-steel offers superior durability, it comes with a higher price tag. PET and PC tubes strike a balance between cost and performance, making them suitable for routine laboratory use. Assessing your budget alongside the specific demands of your experiments will help you choose the most cost-effective option.

Choosing the right material for your ultracentrifuge tubes is critical for the success of your experiments. Whether you need the optical clarity of PET, the durability of PC, or the robustness of stainless steel, aligning the material with your specific needs ensures optimal performance and reliable results. Consider the chemical compatibility, volume requirements, and g-force resistance when making your selection to achieve the best outcomes in your lab work.

Tube Capacity and Size

Selecting the correct capacity and size for your ultracentrifuge tubes is vital for achieving precise and reliable results. The volume of your sample, along with the type of rotor you’re using, will guide your decision on tube size. Here’s how to ensure you’re making the best choice for your experiments.

1. Choosing the Right Capacity

Ultracentrifuge tubes come in various capacities, such as 1 ml ultracentrifuge tubes, ultracentrifuge tubes 1.5 ml, and 2 ml ultracentrifuge tubes. The capacity you choose should match the volume of your sample and the requirements of your centrifugation process. Using a tube that’s too small can lead to incomplete separation, while a tube that’s too large may not provide the necessary centrifugal force to effectively sediment the particles.

2. Matching Tube Size to Rotor Capacity

The rotor you use plays a significant role in determining the appropriate tube size. For example, fixed-angle rotors may accommodate smaller tubes like 1.5 ml micro tubes with snap caps, which are designed to withstand more than 200,000 x g. On the other hand, swing bucket rotors are better suited for larger volumes and can accommodate large volumes effectively, ensuring even distribution and efficient separation.

3. Balancing Tube Volume and Sample Recovery

It’s important to balance the tube volume with the amount of sample you need to recover. Smaller tubes, such as 1 ml or 2 ml ultracentrifuge tubes, are ideal for high-precision work where the recovery of every drop is crucial. Larger tubes are better suited for bulk processing or when dealing with larger volumes of sample, which might be required in preparative ultracentrifugation.

4. Avoiding Overfilling and Underfilling

Proper filling of your ultracentrifuge tubes is essential to prevent imbalances during centrifugation. Overfilling can cause spills and compromise the rotor, while underfilling might not provide the necessary centrifugal force to achieve effective separation. Following the manufacturer’s guidelines for filling levels is key to avoiding these issues.

5. Consideration for High-Speed Applications

For high-speed applications, it’s important to ensure that the tubes you select are designed to handle the specific g-forces involved. 1.5 mL micro tubes with snap caps are engineered to endure extreme conditions, making them suitable for demanding protocols where high g-forces are applied.

Additional Factors in Selecting the Right Ultracentrifuge Tubes

Choosing the right ultracentrifuge tubes involves more than just considering material and size. Several other factors must be taken into account to ensure the tubes meet the specific needs of your application. Here are some key considerations that will help you make the best selection.

1. Separation Technique

The separation technique you’re using will significantly influence your choice of tubes. For example, density gradient centrifugation might require tubes that are compatible with specific gradient media. Conversely, for simple pelletization, standard tubes may suffice. Understanding the demands of your separation technique is essential for choosing the right tube.

2. Sample Type

Different sample types require different tube characteristics. Biological samples, such as cells or proteins, might need ultracentrifuge tubes that are compatible with specific solvents or that provide a gentle environment to prevent sample degradation. For more aggressive samples or those that require high-speed centrifugation, sturdier materials like chemical resistant stainless-steel might be necessary.

3. Solvent or Gradient Media Compatibility

The chemical composition of your solvent or gradient media can interact with the tube material, potentially leading to contamination or tube degradation. Choosing tubes that are resistant to a variety of chemical compounds ensures that your samples remain pure and that the tubes maintain their integrity throughout the centrifugation process.

4. Disposable or Reusable Format

Depending on your lab’s workflow and budget, you may need to choose between disposable and reusable tubes. Autoclavable tubes can be sterilized and reused, making them a cost-effective option for labs that frequently perform similar procedures. Disposable tubes, on the other hand, offer convenience and reduce the risk of cross-contamination between experiments.

5. Transparency: Transparent, Translucent, or Opaque

The transparency of the tube is another important consideration. Transparent tubes allow for easy visual monitoring of your sample during centrifugation. Translucent tubes offer some visibility while also protecting light-sensitive samples. Opaque tubes are ideal when complete protection from light is required, especially for photosensitive materials.

6. Specialized Tube Designs

In some cases, you might need tubes designed for specific post-centrifugation processes. Diaphanous tubes are thin-walled and can be easily sliced or punctured to access the sample without disturbing the pellet. These are especially useful in applications where the purity of the pellet is critical.

7. Chemical and Temperature Resistance

Tubes must often withstand a range of chemical exposures and temperatures. Tubes that are resistant to a variety of chemical compounds ensure compatibility with your experimental conditions. For experiments requiring sterilization, autoclavable tubes are essential, as they can withstand high temperatures without degrading.

Selecting the right ultracentrifuge tubes is crucial for achieving accurate and reliable results in your lab. Each factor, from material and capacity to compatibility with your equipment, directly impacts your experiments. When you carefully consider these aspects, you’re better prepared to handle the unique demands of your work, ensuring that your samples are processed efficiently and safely.

Whether you’re working with high-speed centrifugation, sensitive samples, or specific separation techniques, making informed choices about your tubes is key. With the right ultracentrifuge tubes, you can confidently tackle a wide range of challenges and achieve dependable results in every experiment.