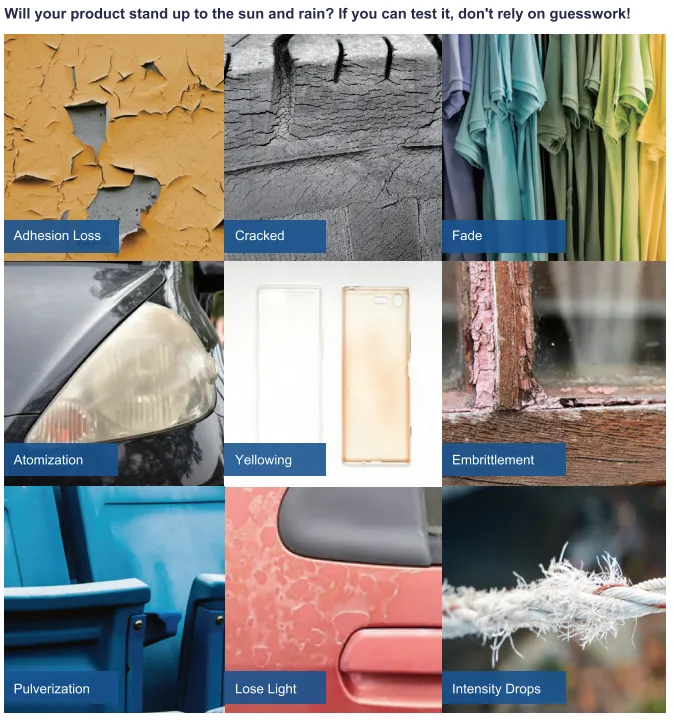

UV Weathering Test Chamber

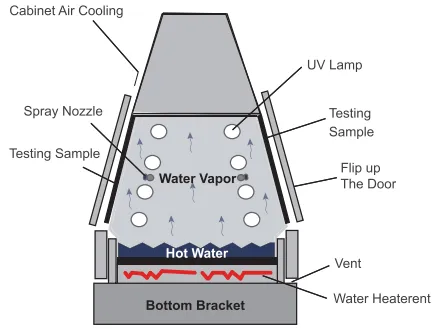

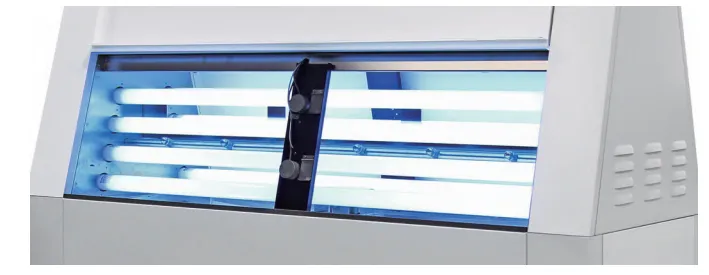

UV Weathering Test Chamber replicates the harmful effects of sunlight, rain, and dew on materials. It condenses months or years of natural weathering into a matter of days or weeks. The testing process alternates between UV light exposure and humidity cycles, with materials subjected to carefully regulated high-temperature conditions.

Fluorescent UV lamps simulate sunlight, while condensation and water spray mimic dew and rain. This process ensures accurate and efficient weathering simulations for assessing material durability.

Real Simulation

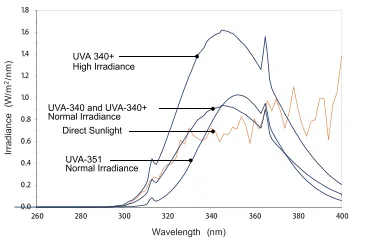

The UV Weathering Test Chamber is equipped with UVA: 340nm lamps, which accurately replicate the short-wavelength spectrum of sunlight. This segment of sunlight is particularly damaging to materials like plastics and paints. This precise simulation ensures reliable results, closely correlating with outdoor exposure conditions.

Cost-Effective Design

Both purchase and operation costs are remarkably economical. The tower-style UV test chamber features an efficient design, using budget-friendly fluorescent UV lamps to mimic sunlight and standard tap water for condensation.

Effortless Operation

With a compact and straightforward design, the chamber is easy to install, operate, and maintain.

- User-friendly interface with intuitive programming

- Continuous monitoring and display of exposure conditions

- Built-in diagnostic alarms and maintenance alerts

Extensive Expertise

Our advanced aging test chambers and services are crafted with extensive experience in standardized weathering testing. Our team actively contributes to ISO, ASTM, IEC, GB, and other global organizations, shaping best practices for material durability assessments.

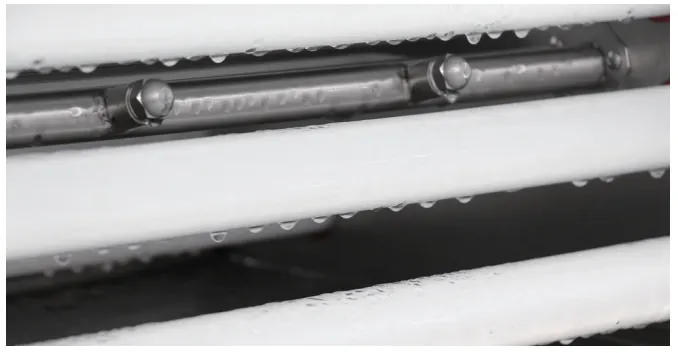

Wet Environment Simulation

The tower-style UV Test Chamber offers two moisture simulation methods: condensation and water spray. While condensation is the primary approach for replicating outdoor moisture damage, the chamber also supports a water spray cycle to meet specific application requirements. This dual functionality ensures a comprehensive simulation of real-world moisture conditions.

Condensation Cycle

In many outdoor settings, materials remain wet for up to 12 hours daily. Studies reveal that dew, rather than rain, is the leading cause of outdoor wetness. To replicate this, the tower UV Test Chamber uses a unique condensation feature. During this cycle:

The cooling effect of the surrounding air reduces the sample surface temperature slightly below that of the water vapor. This temperature difference ensures continuous condensation of water vapor on the sample surface.

The condensed water is stable, pure distilled water. Even when ordinary tap water is used, the water collected on the sample surface remains free of impurities, delivering reliable testing conditions for material durability assessments.

Real Simulation

Dew, not rain, is responsible for most of the humidity in outdoor exposures.

Condensation: Reliable and Efficient Moisture Simulation

Water Spray: Simulating Thermal Shock and Mechanical Erosion

The water spray feature replicates real-world conditions where sudden rain showers cool sun-heated materials, causing rapid temperature changes. This process tests materials for their ability to withstand thermal shock. Additionally, the water spray simulates the mechanical erosion caused by rainfall, assessing the durability of materials against such wear and tear.

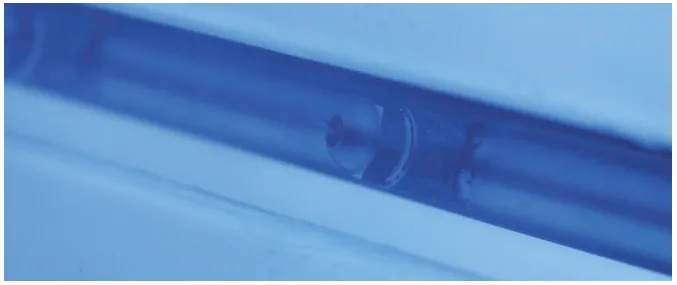

UV and Sunlight Simulation

Ultraviolet light is a leading cause of photodegradation in outdoor products. The UV Weathering Test Chamber uses advanced fluorescent UV lamps to replicate the critical short-wave UV light found in sunlight, effectively simulating the aging effects on materials caused by prolonged exposure to light.

UV Lamp Options

The chamber offers a range of high-quality UV fluorescent lamps to accommodate various testing conditions. These lamps feature:

This combination of precise simulation and reliable components ensures accurate and repeatable testing results.

UVA Lamps: Precision Sunlight Simulation

UVA lamps provide accurate replication of sunlight in critical UV regions, making them essential for material durability testing:

- UVA340 Lamps: Simulate the short-wavelength UV spectrum of sunlight, specifically between 365nm and 295nm, effectively replicating the most damaging rays.

- UVA351 Lamps: Designed to mimic UV light that passes through window glass, ideal for testing indoor exposure effects.

- Cool White Lamps: Suitable for simulating artificial lighting conditions, such as those in office environments.

Each lamp undergoes a rigorous series of tests to ensure performance consistency and quality, delivering reliable results for a variety of testing scenarios.

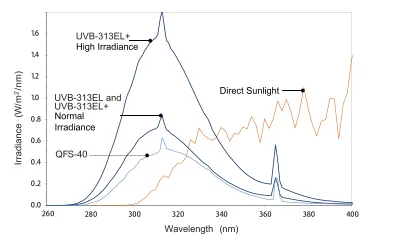

UVB Lamps: High-Intensity UV Testing Solutions

UVB lamps offer enhanced ultraviolet light for rigorous testing of material durability:

- UVB313EL Lamps: Emit short-wave UV light stronger than natural sunlight at the Earth's surface, ideal for:

- Quality control procedures.

- Product development processes.

- Testing materials with high weather resistance.

- UVB311EL+ Lamps: Deliver exceptionally high irradiance levels, making them suitable for demanding fluorescent UV tests requiring intensified conditions.

These lamps provide reliable tools for simulating extreme UV exposure, ensuring precise evaluation of material performance.

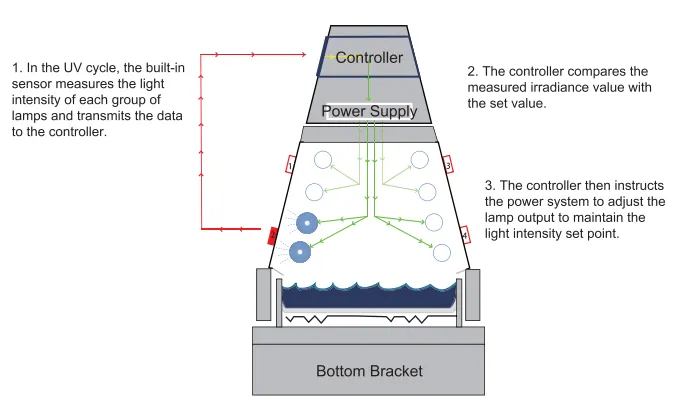

Irradiance Control: Ensuring Accurate and Consistent Testing

The intensity and spectrum of UV light directly influence the rate and type of material aging. Accurate control of irradiance is crucial for reliable and repeatable test results.

This advanced control ensures that weathering tests provide consistent, reliable data for evaluating material performance.

Product Categories

Benchtop UV Weathering Test Chamber ToronUV-100

Benchtop UV Weathering Test Chamber ToronUV-100 features three 20W fluorescent UV lamps with wavelengths of 313nm (or 340nm), providing an ideal light source for...

UV Weathering Test Chamber ToronUV-200

Sunlight and humidity cause billions of dollars in material damage each year. The UV Weathering Test Chamber ToronUV-200 performs alternating UV and humidity cycle aging tests on materials...

UV Weathering Test Chamber ToronUV-300

UV Weathering Test Chamber ToronUV-300 features a high-precision LCD controller for temperature and humidity management with PID auto-tuning, customizable programs...