Product failures caused by vibrations during transit or operation can lead to costly recalls and damage to your reputation. Manufacturers need reliable solutions to ensure their products withstand real-world conditions. A well-equipped vibration testing laboratory provides the tools to validate durability, optimize designs, and meet stringent industry standards.

This article highlights the advanced equipment used in our vibration testing laboratory, their unique advantages, and the industries they serve. Discover how these tools can transform your product validation process.

How Vibration Testing Equipment Ensures Product Durability and Compliance

Vibration testing equipment replicates real-world stresses, enabling manufacturers to identify weak points, validate designs, and ensure compliance with regulatory standards.

These tools go beyond simple testing; they provide actionable insights to optimize materials, improve product resilience, and prevent costly failures.

Whether it’s simulating transportation conditions or operational stresses, advanced vibration testing systems are important for delivering reliable and durable products.

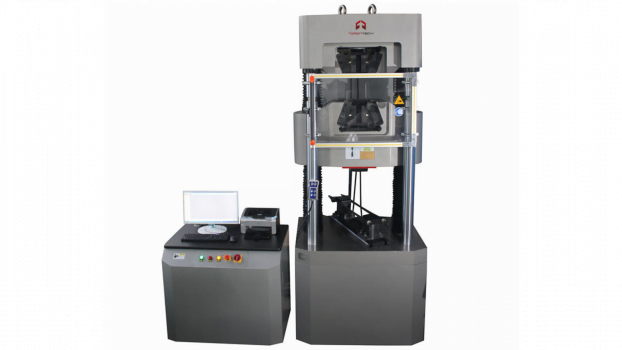

Key Equipment in Torontech’s Vibration Testing Laboratory Equipments

Torontech provides a comprehensive range of advanced vibration testing equipment, meticulously designed to meet specific applications and industry needs. Each system adheres to stringent international standards, ensuring precise and reliable testing for various products.

Below is an overview of our flagship equipment, their features, and the standards they comply with.

1. Electrodynamic Shaker Vibration Test System

The Electrodynamic Shaker Vibration Test System is a versatile system designed to simulate complex vibration environments in laboratory settings.

It evaluates impact strength and reliability under various conditions, including sinusoidal, random, resonant search and dwell, classical shock, and road simulations.

- Compliance: Conforms to MIL-STD, DIN, ISO, ASTM, IEC, ISTA, GB, GJB, JIS, and BS standards.

- Applications: Important for aerospace, automotive, consumer electronics, and research and development.

2. Shock Test System

The Shock Test System replicates real-world impacts such as free falls, tumbling, and bumps to assess structural strength and stability under transient excitation conditions.

By selecting different waveform generators, it can produce half-sinusoidal, sawtooth, or trapezoidal waves to test various mechanical characteristics.

- Applications: Frequently used in industries such as consumer electronics, automotive, and display devices.

3. Mechanical Vibration Tester

The Mechanical Vibration Tester is a reliable solution for simulating transport vibrations in electronic products, spare parts, and instrumentation. It reproduces real-world vibration conditions to ensure product reliability and durability during transit.

- Compliance: Complies with GB, UL, IEC, and other international standards.

- Applications: Commonly used in consumer electronics, industrial equipment, and packaging validation.

4. Bump Test Machine

The Bump Test Machine ensures product durability against repeated impacts experienced during transportation or regular use.

It validates design structures and serves as a critical quality assurance method. Specimens undergo regular peak accelerations and continuous impacts with standardized pulses to test structural integrity.

- Applications: Widely used for testing automotive components, heavy machinery, electronics, and renewable energy equipment.

5. Transportation Simulator

The Transportation Simulator is essential for evaluating packaging effectiveness and product safety during transit. It performs repeated impact, unloading, and jump tests, replicating real-world transportation conditions.

The system supports vibration modes, including rotation (marquee), vertical, and non-synchronized (30° unbalanced vibration), achieved through its eccentric cam mechanism.

- Compliance: Meets ISTA, ASTM, TAPPI, ISO, MIL-STD, FED-STD, UN, DOT, and other industrial and government standards.

- Applications: Ideal for the packaging, logistics, and manufacturing industries to prevent transit-related damages.

Torontech’s vibration testing equipment portfolio offers solutions that combine precision, adaptability, and compliance with international standards. These systems empower businesses across various sectors to ensure their products are durable, reliable, and ready for market demands.

Why Choose Torontech’s Vibration Testing Equipment?

Our advanced equipment offers unparalleled benefits for businesses seeking reliable product testing solutions:

- Comprehensive Testing Capabilities: Covers vibration, shock, bump, and transportation simulations.

- High Precision: Delivers accurate, repeatable results for thorough product analysis.

- Customizable Solutions: Adapts to specific product requirements, testing standards, and industry needs.

- Global Compliance: Meets ISO 9001, MIL-STD-810G, ASTM, and other international standards.

- Versatility Across Industries: Suitable for a wide range of applications, from aerospace to consumer electronics.

Industries That Rely on Vibration Testing Equipment

Vibration testing is essential across diverse industries, addressing unique challenges and ensuring product reliability under real-world conditions. These labs enable manufacturers to meet performance standards, maintain compliance, and protect their reputation.

1. Aerospace

Aircraft components endure intense vibrations during turbulence, takeoffs, and landings. Testing ensures parts like engines and electronics meet strict standards such as MIL-STD-810G and operate reliably in extreme conditions.

2. Automotive

Parts like engines, suspensions, and electronic systems must withstand road vibrations and operational stress. Testing prevents failures, enhances safety, and ensures vehicles meet industry benchmarks.

3. Electronics and Consumer Products

Devices such as smartphones, laptops, and industrial equipment face vibrations during transit and use. Testing ensures circuit boards, connectors, and other components remain functional, reducing product returns and improving customer trust.

4. Packaging and Logistics

Transport vibrations often damage fragile goods. Testing optimizes packaging designs to minimize breakage, improve sustainability, and protect items like medical devices, glassware, and electronics.

5. Defense and Military

Military systems operate in harsh environments where vibrations are constant. Testing ensures weapons, communication devices, and equipment remain operational under extreme conditions and comply with strict defense standards.

6. Renewable Energy

Wind turbines and solar panels endure environmental forces over long periods. Testing validates their durability and efficiency, ensuring they continue to perform reliably.

Each industry depends on vibration testing to deliver reliable, compliant products that perform effectively in demanding environments.

Final Thought

Vibration testing laboratories equipped with advanced tools are essential for validating product durability and performance across industries. From aerospace components to consumer electronics, our cutting-edge equipment ensures precision, reliability, and compliance at every stage of testing.

Whether you need to validate a new design, optimize packaging, or meet regulatory standards, our vibration testing solutions deliver the results you need. Explore our Vibration Testing Laboratory Equipment and see how we can help you achieve product excellence.