Xenon Accelerated Weathering Test Chamber - Xenon Accelerated Weathering Test Chamber - ToronXTC-1000H

Xenon Accelerated Weathering Test Chamber - ToronXTC-1000H

Xenon Accelerated Weathering Test Chamber - ToronXTC-1000H is a high-performance xenon aging test chamber designed to simulate the damaging effects of full-spectrum sunlight, heat, and humidity. It reproduces the aging impact of months or years of outdoor exposure within days or weeks, providing rapid and reliable results.

Standards

- ASTM D3451: Testing of Coating Powders and Powder Coatings

- ASTM D3794: Testing of Coil Coatings

- ASTM D6577: Testing Overview for Industrial Protective Coatings

- ASTM D6695: Xenon Arc Exposure of Paints and Related Coatings

- ASTM G151: Nonmetallic Materials Exposure Overview

- ASTM G155: Xenon Arc Test Equipment for Exposure of Non-Metallic Materials

- ISO 4892: Plastics - Laboratory Light Exposure Methods

- ISO 16474-2: Paints and Varnishes - Artificial Aging and Exposure to Radiation from Filtered Xenon Lamps

- JKS K 5600-7-7: Test Methods for Coatings - Part 7: Accelerated Weathering Test (Exposure to Filtered Xenon Arc Lamp Radiation)

- GB/T 1865: Artificial Weathering and Artificial Radiation Exposure - Filtered Xenon Arc Radiation for Paints and Varnishes

- GB/T 16422.1: Plastic Laboratory Light Source Exposure Test Method - Part 1: General

- GB/T 16422.2: Plastic Laboratory Light Source Exposure Test Method - Part 2: Xenon Arc Lamp

- GB/T 16259: Building Materials - Artificial Climate Accelerated Aging Test Method

- GB/T 8427: Color Fastness Test of Textiles to Artificial Light: Xenon Arc

- GB/T 12831: Vulcanized Rubber - Artificial Climate (Xenon Lamp) Aging Test Method

- GB/T 16991: Textile Color Fastness Test - High Temperature Artificial Light Color Fastness and Anti-Aging Performance (Xenon Arc)

- GB/T 14576: Textile Color Fastness Test - Light Fastness and Perspiration Composite Color Fastness

- GB/T 15104: Decorative Veneer Wood-Based Panel

- GB/T 2423.24: Environmental Test - Part 2: Test Method Sa Simulates Solar Radiation on the Ground and Its Test Guide

Advantages

- Advanced Xenon Lamp Technology: Utilizes a 1.8 KW air-cooled long arc xenon lamp for precise and reliable testing.

- User-Friendly Design: Engineered for ease of use, ensuring the best sample loading experience.

- Versatile Testing Capabilities: Fully equipped for weathering, colorfastness, and lightfastness tests, adhering to all major industry standards.

- Cost-Effective Operation: Offers an economical solution with low purchase and operating costs.

- High-Quality Equipment and Services: Provides premium aging test machines alongside professional testing services.

- Comprehensive After-Sales Support: Backed by an experienced team for installation, maintenance, training, and consulting.

- Simplified User Interface: Intuitive and easy to program, saving time and effort during operation.

- Durable Xenon Lamps: Long-lasting lamps with a service life of up to 1,500 hours, offering excellent value.

- Customizable Filters: Offers a variety of optical filter options, meeting diverse domestic and international testing standards.

This chamber is designed to deliver top-tier performance while remaining cost-effective, making it an ideal choice for advanced testing applications.

Service system

- Defining Product Specifications: Collaborate to identify and finalize detailed requirements tailored to your needs.

- Layout Design: Develop optimized designs for functionality, efficiency, and usability.

- Production and Commissioning: Oversee manufacturing and commissioning processes with strict quality control.

- Installation and Commissioning: Deliver seamless setup and ensure proper functionality of the system.

- User Training and Maintenance: Provide training on product usage, safety precautions, and routine maintenance to maximize operational efficiency.

Applicable industries

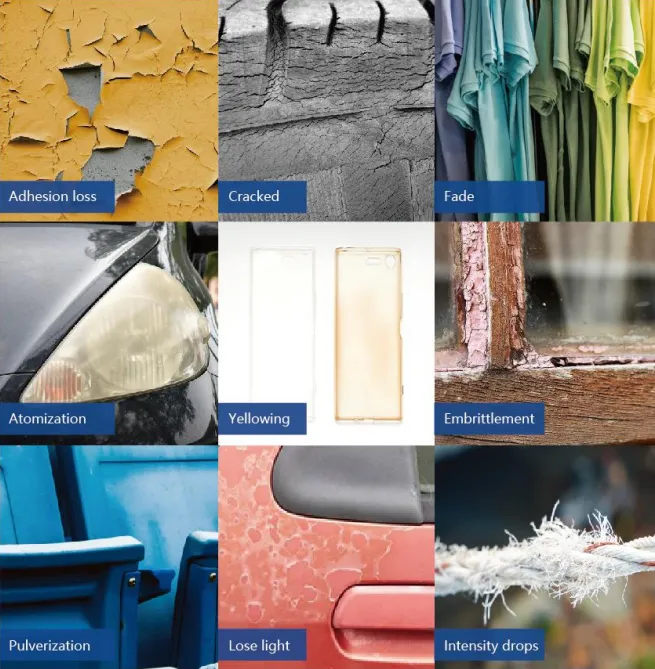

Fluorescent UV aging tests are a critical standard for evaluating the weather resistance of various paints and coatings. Both national and chemical industry standards mandate their use for the following:

- Marine Coatings: Hull paint, waterline paint, and deck paint designed for harsh maritime conditions.

- Wood Finishes: Solvent-based and water-based polyurethane paints for interior decoration, as well as UV-curing wood paints.

- Specialized Coatings: Pre-coated coil coatings for home appliances, indoor water-based wood coatings, and architectural water-based fluorine coatings.

Typical Applications:

These tests extend beyond paints and coatings, supporting industries such as:

- Automotive: Ensuring the durability of exterior and interior finishes.

- Plastics: Assessing the longevity and resistance of plastic components.

- Wood Products: Testing the resilience of finishes applied to wooden surfaces.

- Adhesives: Evaluating the long-term performance of glues and bonding materials.

Fluorescent UV testing provides reliable, accelerated simulations of weathering, enabling manufacturers to ensure the durability and quality of their products in demanding environments.

Key Features

- U.S.-made xenon light source and original filter simulate the full spectrum of sunlight for realistic and optimal testing conditions.

- Stable light source ensures reliable, reproducible test data.

- Xenon lamp has a service life of up to 1500 hours, with indicators meeting the highest international standards.

- Optional filters available: UV extension filter, daylight filter, or window glass filter, compatible with multiple domestic and international testing standards.

- Precise control over irradiance and temperature, with the Black Panel temperature adjustable to the desired level. Irradiance control is independently adjustable.

- Real-time data collection and storage: Test data is automatically recorded in EXCEL format and can be exported via USB drive for fully unattended operation.

- Touch screen interface with user-friendly controls allows operators to set test parameters and monitor the process status in real time.

- High-precision Pt 100 Black Panel temperature sensor and black mark temperature sensors automatically control the sample room temperature (room temperature to 90°C).

- Alarm protection functions for large irradiance errors, over-temperature, and heating overloads.

- Accelerated aging: The test chamber exposes samples to equivalent summer noon sunlight, 24 hours a day, rapidly aging the sample.

- Affordable solution with low purchase price, low lamp costs, and minimal operating expenses, making Xenon arc testing accessible to even small labs.

| Specification | Details |

|---|---|

| Xenon lamp | 1.8KW air-cooled long arc Xenon lamp(Made in US) |

| Filter | UV extension filter (can also choose daylight filter or window glass filter) |

| Exposure area | 1000 cm² (9 pieces of 150mm×70mm standard samples can be exposed to the sun at one time) |

| Irradiance monitoring point | 340nm, 420nm, 300nm~400nm (optional) |

| Irradiance range |

0.3W/m²~0.8W/m² (340nm) 0.5W/m²~1.35W/m² (420nm) 30W/m²~100W/m² (300nm~400nm) 200W/m²~1000W/m² (280nm~800nm) |

| Lamp life approx. | 1800 hours |

| Black Panel Temperature range | RT~90°C |

| External Dimensions | 1000mmx650mmx1020mm |

| Weight approx. | 135kg |

| Voltage | 220V, 50Hz or 60Hz (110V is also available) |