Xenon Accelerated Weathering Test Chamber - Xenon Accelerated Weathering Test Chamber - ToronXTC-2200H

Xenon Accelerated Weathering Test Chamber - ToronXTC-2200H

Xenon Accelerated Weathering Test Chamber - ToronXTC-2200H is a high-performance xenon aging test chamber designed to simulate the damaging effects of full-spectrum sunlight, high temperatures, and humidity. This chamber can replicate the aging effects of months or even years of outdoor exposure in just a few days or weeks, making it ideal for accelerated testing.

Standards

- ASTM G151: Standard Practice for Exposing Nonmetallic Materials in Accelerated Test Devices That Use Laboratory Light Sources

- ASTM G155: Standard Practice for Operating Xenon Arc Light Apparatus for Exposure of Non-Metallic Materials

- ISO 11341: Paints and Varnishes - Artificial Weathering and Exposure to Artificial Radiation - Exposure to Filtered Xenon-Arc Radiation

- ISO 4892: Plastics - Methods of Exposure to Laboratory Light Sources - Part 2: Xenon-Arc Lamps

- SAE J2527: Performance Standard for Accelerated Irradiation of Automotive Exterior Materials by Xenon Arc Lamp Radiators

- SAE J2412: Accelerated Aging of Automotive Interior Components Using a Controlled Irradiance Xenon Arc Device

- GB/T 1865: Paints and Varnishes - Artificial Weathering and Artificial Radiation Exposure - Filtered Xenon Arc Radiation

- GB/T 16422.1: Plastics - Laboratory Light Source Exposure Test Method - Part 1: General

- GB/T 16422.2: Plastics - Laboratory Light Source Exposure Test Method - Part 2: Xenon Arc Lamp

- GB/T 16259: Building Materials - Artificial Climate Accelerated Aging Test Method

- GB/T 8427: Textiles - Test for Colour Fastness - Colour Fastness to Artificial Light: Xenon Arc

- GB/T 12831: Vulcanized Rubber - Artificial Climate (Xenon Lamp) Aging Test Method

- GB/T 16991: Textiles - Color Fastness Test - High Temperature Resistance to Artificial Light - Color Fastness and Anti-Aging Properties (Xenon Arc)

- GB/T 14576: Textiles - Test for Color Fastness - Composite Color Fastness to Light and Perspiration

- GB/T 15104: Decorative Veneer - Veneer Wood-Based Panel

- GB/T 2423.24: Environmental Test - Part 2: Test Methods - Test Sa Simulates Solar Radiation on the Ground and Its Test Guidelines

Advantages

- Powerful Xenon Lamp: Equipped with a 1.8 KW air-cooled long arc Xenon lamp(Made in US) for reliable and efficient testing.

- User-Centric Design: Optimized for ease of use, offering the best solutions for sample handling and loading.

- Comprehensive Testing Capabilities: Fully functional chambers designed for aging resistance, colorfastness, and lightfastness, adhering to all major industry standards.

- Premium Components: Premium functional parts to ensure top-notch performance and durability.

- Cost-Effective: Delivers high-quality performance with affordable purchase and operating costs.

- High-Quality Services: Offers robust aging test chambers along with professional testing services.

- Expert Support: Backed by an experienced team for installation, maintenance, training, and consulting.

- User-Friendly Interface: Simple, intuitive programming for seamless operation.

- Enhanced Safety: Equipped with over ten protection configurations for greater operational security.

- Full-Spectrum Sunlight Simulation: Accurately reproduces ultraviolet, visible, and infrared light for realistic environmental testing.

- Smart Diagnostics: Includes self-diagnostic alarms and maintenance reminders to ensure smooth and efficient operation.

This test chamber offers a perfect blend of advanced technology, reliability, and cost-efficiency, making it an ideal choice for demanding aging and durability assessments.

Service system

- Product Specifications: Collaborate with you to define and finalize detailed product specifications tailored to your specific needs.

- Layout Design: Develop optimized layouts for functionality, ease of use, and space efficiency, ensuring the best user experience.

- Production and Commissioning: Oversee the production process with strict quality control and supervise the commissioning phase to ensure everything meets high standards.

- Installation and Commissioning: Provide on-site installation services, ensuring the system is properly set up and functioning as intended.

- Training and Maintenance: Offer comprehensive training on product usage, safety precautions, and routine maintenance, ensuring your team operates the system efficiently and safely.

We are dedicated to delivering seamless service throughout the product lifecycle, ensuring quality, reliability, and long-term success.

Applicable industries

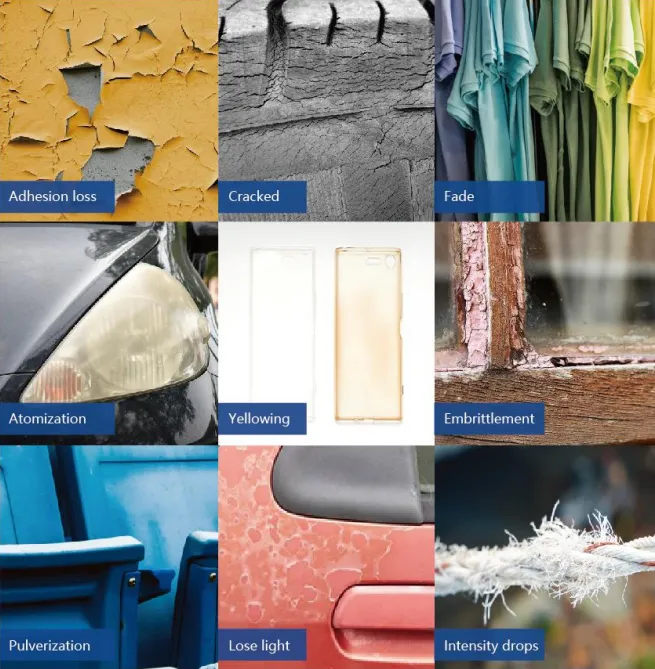

Fluorescent ultraviolet (UV) aging tests are a critical standard in the paint and coatings industry, used to evaluate the weather resistance of a wide range of products. The following materials are required to undergo UV aging tests according to national and chemical industry standards:

- Marine Coatings: Hull paint, waterline paint, and deck paint designed to withstand harsh marine environments.

- Wood Finishes: Solvent-based and water-based polyurethane paints for interior decoration, along with UV-curing wood paints.

- Specialized Coatings: Pre-coated coil coatings for home appliances, indoor water-based wood coatings, coil coatings, and architectural water-based fluorine coatings.

Typical Applications:

Fluorescent UV aging tests are used across various industries, including:

- Paint and Coatings: Ensuring the durability and longevity of exterior and interior coatings.

- Automotive: Testing the performance and weathering of automotive finishes.

- Plastic Products: Assessing the impact of UV exposure on plastics.

- Wood Products: Evaluating the resilience of wood finishes in different environmental conditions.

- Adhesives: Testing the weather resistance of glues and bonding agents.

These tests replicate real-world environmental conditions, offering a fast and accurate way to predict the long-term performance and durability of materials exposed to sunlight, heat, and humidity.

Key Features

- Xenon Light Source & Filter: Made in United States, accurately simulates the full spectrum of sunlight for optimal and realistic testing.

- Uniform Irradiation: Drum-shaped sample holder rotates automatically, ensuring even energy distribution across all test panels.

- Automated Energy Control: Sun Eye Control System provides precise and stable irradiation energy, compensating for variations due to lamp aging. Adjustable range:

- 0.30 W/m²-0.75 W/m² @ 340 nm

- 0.5 W/m²-1.35 W/m² @ 420 nm

- 0 W/m²-90 W/m² @ 300-400 nm

- Long Lamp Life: Xenon lamp lasts up to 1,500 hours, meeting the highest international standards.

- Flexible Filters: Multiple internal and external optical filters available, which can be replaced during testing to maintain light transmittance and meet international test standards.

- Precise Environmental Control:

- Temperature control (black panel, black scale, or inner chamber temperature) with a range from room temperature to 100°C.

- Irradiance control at 340 nm or 420 nm.

- Humidity control from 20% to 95%.

- Customizable Test Programs:

- 9 programmable test programs (each with 10 data segments).

- 6 preset international standard programs.

- Data Collection & Storage: Test data automatically recorded in Excel format, exportable via USB for hands-free operation.

- User-Friendly Touch Screen: Allows easy parameter setup and real-time monitoring of the test process.

- Precision Sensors: High-precision Pt 100 black panel and black scale temperature sensors for accurate temperature control.

- Alarm Protection: Alerts for issues such as large irradiance errors, high cooling water temperature, and low water flow.

- Ease of Use & Low Maintenance: Simple to use, virtually maintenance-free, and designed for any testing environment.

- Adjustable Test Plate Frame: Ensures uniform irradiation and better data consistency across tests.

- Accelerated Aging: Exposes samples to sunlight equivalent to peak summer noon hours, 24/7, speeding up the aging process.

- Cost-Effective: Low purchase price, affordable lamp costs, and low operating expenses, making the ToronXTC-2200H accessible for even small labs.

| Specification | Details | |

|---|---|---|

| Xenon lamp | 1.8KW air-cooled long arc Xenon lamp(Made in US) | |

| Filter | Daylight filter (Window glass filter or UV extension filter also available) | |

| Exposure area | 2200 cm²(22pcs standard samples of 150mm×70mm can be exposed to the sun at one time) | |

| Irradiance monitoring point | 340nm, 420nm, 300nm~400nm (300nm~800nm) | |

| Automatic irradiation control |

(0.30W/m²-0.75W/m²) @340nm (0.5W/m²-1.35W/m²) @420nm (0W/m²-90W/m² )300nm-400nm |

|

| Lamp life approx. | 1500 hours | |

| Temperature range | Black panel | Black label |

| RT+30℃~100℃ | RT+30℃~100℃ | |

| Cabinet air | RT+10℃~65℃ | |

| Humidity range | Light:10%-75% spray or dark cycle:10%-95% |

|

| Note: The temperature range is slightly different depending on the external environment andtheset irradiance | ||

| Sample Rotating Speed | 1r/min(around the center of the tube) | |

| Sample Tray Load Capacity | Up to 4.5kg | |

| Inlet Pressure | 2.8-5.5 bar | |

| Influent Water Purity | Deionized water with conductivity < 0.1 μS and silica content < 0.2ppm | |

| Water Consumption | 1.0 L/min (Spray) 8 L/day (humidified) |

|

| Humidification gas source | 0.3~0.8Mpa | |

| External Dimensions(W×D× H) | 865mm×800mm×1780mm | |

| Weight approx. | 240kg | |

| Voltage | 380V,50Hz | |