Xenon Accelerated Weathering Test Chamber - Xenon Accelerated Weathering Test Chamber - ToronXTC-6500H

Xenon Accelerated Weathering Test Chamber - ToronXTC-6500H

Xenon Accelerated Weathering Test Chamber - ToronXTC-6500H is designed to simulate the harmful effects of full-spectrum sunlight, high temperatures, and humidity, accelerating the aging process of materials. By using a xenon lamp, it effectively reproduces sunlight, while its water spray system mimics the effect of rain. The chamber allows for precise control of irradiation energy and temperature throughout the testing cycle, enabling accelerated weathering that would otherwise take months or years to occur outdoors.

Standards

- ASTM D3451: Testing of Coating Powders and Powder Coatings

- ASTM D3794: Testing of Coil Coatings

- ASTM D6577: An Overview of Testing for Industrial Protective Coatings

- ASTM D6695: Xenon Lamp Exposure of Paints and Related Coatings

- ASTM G151: Overview of Exposure to Non-Metallic Materials

- ASTM G155: Xenon Arc Test Equipment for Exposure of Non-Metallic Materials

- ISO 4892: Plastics - Laboratory Light Exposure Method

- ISO 11341: Paints and Varnishes - Artificial Aging and Exposure to Filter Radiation Exposure from Xenon Lamps

- JKS K 5600-7-7: Test Methods for Coatings - Part 7: Accelerated Weathering Test (Exposure to Filtered Xenon Arc Lamp Radiation)

- GB/T 1865: Artificial Weathering and Artificial Radiation Exposure - Filtered Xenon Arc Radiation for Paints and Varnishes

- GB/T 16422.1: Plastics Laboratory Light Source Exposure Test Methods - Part 1: General

- GB/T 16422.2: Plastics Laboratory Light Source Exposure Test Methods - Part 2: Xenon Arc Lamps

- GB/T 16259: Building Materials - Artificial Climate Accelerated Aging Test Method

- GB/T 8427: Textile Color Fastness Test - Color Fastness to Artificial Light: Xenon Arc

- GB/T 12831: Vulcanized Rubber - Artificial Climate (Xenon Lamp) Aging Test Method

- GB/T 16991: Textile Color Fastness Test - High-Temperature Artificial Light Color Fastness and Anti-aging Performance (Xenon Arc)

- GB/T 14576: Color Fastness Test of Textiles to Light and Perspiration Composite Color Fastness

- GB/T 15104: Decorative Veneer Wood-Based Panel

- GB/T 2423.24: Environmental Test Part 2 - Test Methods - Test Sa Simulates Solar Radiation on the Ground and Its Test Guide

Advantages

- 6.5 kW Water-Cooled Long Arc Xenon Lamp(Made in US) for Precision Testing

- Features a user-friendly design to simplify sample handling and loading.

- Advanced test chambers for aging resistance, colorfastness, and lightfastness that align with all major testing standards.

- Incorporates high-performance components sourced from Europe.

- Offers cost-effective solutions for both purchase and operation.

- Delivers premium aging test chambers and reliable testing services.

- Supported by a skilled after-sales team specializing in installation, maintenance, training, and consulting.

- Designed with an intuitive user interface for effortless programming.

- Enhanced safety with over ten protection configurations.

- Accurately replicates the full spectrum of sunlight, including ultraviolet, visible, and infrared light.

- Equipped with self-diagnostic alarms and maintenance alerts for efficient operation.

Service system

- Determine Product Specifications: Customized to meet specific testing needs and industry standards.

- Layout Design: Optimized chamber layout for efficient sample loading and testing.

- Producing/Commissioning: High-quality production with rigorous testing and commissioning to ensure performance.

- Installation and Commissioning: Professional installation and setup for seamless integration.

- Product Use Training, Precautions, Routine Maintenance: Full training on chamber operation, best practices, and ongoing maintenance to ensure longevity and reliability.

Applicable industries

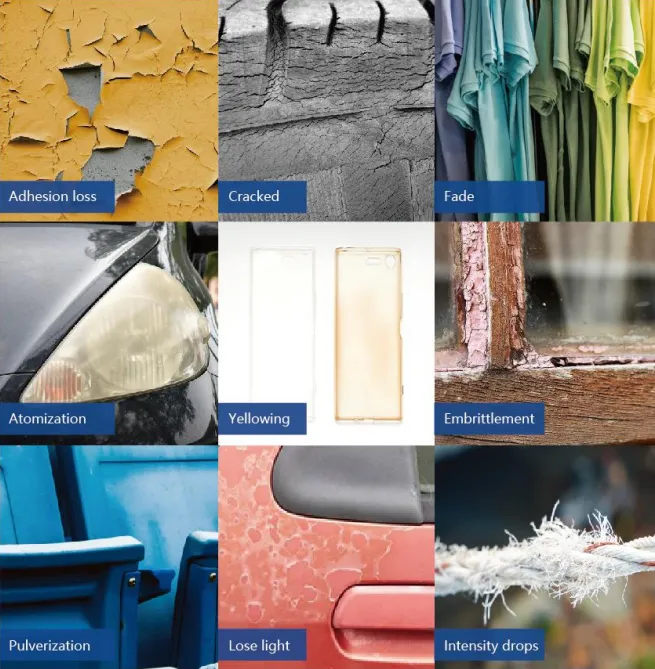

The Xenon Accelerated Weathering Test Chamber - ToronXTC-6500H is widely used in industries such as paint, automotive, and plastic manufacturing to evaluate the weather resistance of various coatings. It is designed to simulate the effects of full-spectrum sunlight, high temperatures, and humidity on materials like hull paint, marine waterline paint, polyurethane wood paint, UV-curing wood paint, and more. The chamber is essential for assessing the durability and performance of coatings, ensuring that they meet the national standards for outdoor weathering, including colorfastness and aging resistance testing. Typical applications include testing for paint coatings, automotive components, plastic, wood products, and adhesives.

Key Features

- The xenon light source and original filters, made in the United States, simulate the full spectrum of sunlight with greater realism and efficiency. The stable light source ensures consistency and reproducibility of test data.

- The drum-shaped sample holder rotates automatically, ensuring uniform irradiation energy distribution across all test panels within the chamber.

- Fully automatic irradiation energy control system (using the sun-eye control system) offers precise stability, compensating for energy fluctuations caused by lamp aging or other factors. The energy control range is wide:

- 0.30W/m²-1.5 W/m² @ 340nm

- 0.75 W/m²-2.8 W/m² @ 420nm

- 30W/m²-150 W/m² @ 300-400nm

- The xenon lamp has a service life of up to 2000 hours, meeting the highest international standards.

- A variety of internal and external optical filters are available, and they can be replaced during testing to ensure consistent light transmittance and optical parameters, meeting both domestic and international standards.

- Precise control of irradiance, temperature, and humidity, with the ability to set control targets for black panel temperature, black scale temperature, or inner chamber temperature. The humidity control range is 30% - 95%.

- Up to 9 customizable test programs and 6 preset international standard programs can be stored. Each of the 9 programmable programs allows for 10 data segments.

- Real-time data collection and storage, with automatic recording and saving in EXCEL format, enabling easy data export via USB. This allows for truly unattended operation.

- The intuitive touch screen interface allows operators to adjust test parameters and monitor the testing process with ease.

- The high-precision Pt 100 black panel temperature sensor and black scale temperature sensor provide automatic temperature control within the sample room, with a range from room temperature to 100°C.

- Built-in alarm protection functions include warnings for large irradiance errors, high electrical conductivity of pure water, excessive cooling water temperature, water shortage in the cooling tank, low cooling water flow, overheating, and heating overload.

- The Xenon Accelerated Weathering Test Chamber - ToronXTC-6500H is user-friendly and virtually maintenance-free, with easy setup in any room.

- The adjustable test plate frame ensures optimal irradiation uniformity, improving data comparability across test panels.

- Fast results: Unlike outdoor exposure, which requires several hours of direct sunlight, the B-SUN test chamber provides 24/7 exposure equivalent to noon sunlight in summer, allowing for rapid aging of samples.

- Cost-effective: The ToronXTC-6500H delivers high value with a low purchase price, affordable lamp costs, and low operational expenses, making xenon arc testing accessible for even small labs.

| Specification | Details | ||

|---|---|---|---|

| Xenon Lamp | 6.5KW water-cooled long arc xenon lamp (Made in US) | ||

| Filter | Original Fully simulates the indoor or outdoor solar spectrum | ||

| Exposure Area | 6500 cm² (63 to 65 standard samples of 150mm × 70mm can be exposed to the sun at one time) | ||

| Irradiance Monitoring Point | 340nm 420nm 300nm~400nm 300nm~800nm |

||

| Lamp Life | 2000 hours | ||

| Temperature Range | Category | Black Panel | Black Mark |

| Light Cycle | 50°C~100°C | 55°C~105°C | |

| Light Cycle (use IR filter) | 35°C~85°C | 40°C~90°C | |

| Dark Cycle | 25°C~45°C | 25°C~45°C | |

| Light + Immersion Cycle | 35°C~55°C | 35°C~55°C | |

| Dark + Immersion Cycle | 30°C~50°C | 30°C~50°C | |

| Cabinet Air Temperature | Light cycle(Arbitrary filter) | 35°C~65°C | |

| Dark Cycle | 25°C~45°C | ||

| Temperature Fluctuation | ±1°C | ||

| Temperature Uniformity | ≤2°C | ||

| Temperature Deviation | ≤±1°C | ||

| Humidity Range | Light:10%-75% No Light:10%-95% |

||

| Sample Rotating Speed | 1r/min (around the center of the tube) | ||

| Sample Tray Load Capacity | Up to 4.5kg | ||

| Inlet Pressure | 2.8~5.5 bar | ||

| Influent Water Purity | Deionized water with conductivity < 0.1 µS and silica content < 0.2 ppm | ||

| Water Consumption | 0.5 L/min (Front spray) | ||

| 1.0 L/min (Rear spray) | |||

| 8 L/day (Humidification) | |||

| Dimensions (W x D x H) | 1220mm × 1200mm × 2050mm | ||

| Weight | 500kg | ||

| Power Requirements | 380V, 50Hz, Maximum current 32A | ||

Please Contact us for pricing, check availability, or ask for additional information about our Xenon Accelerated Weathering Test Chamber – ToronXTC-6500H