Plastic waste has become a pressing environmental issue, with millions of tons ending up in landfills and oceans yearly. Among the various types of plastic, PET (Polyethylene Terephthalate) has become ubiquitous in our modern lives, finding their way into countless products and packaging. However, their improper disposal and slow degradation rate have led to a staggering accumulation of plastic waste in landfills, oceans, and natural habitats. The need for effective solutions, such as PET Recycling Line to tackle this crisis has never been more critical.

PET recycling lines, including PET bottle recycling lines and PET bottle washing lines, have emerged as game-changers in the battle against plastic waste. These advanced systems, including the best pet recycling lines, are designed to efficiently process PET plastics, transforming them into valuable resources while minimizing their impact on the environment. By recycling plastics such as PET, we can contribute to reducing the amount of plastic used and advocate for a more sustainable future.

Understanding PET Plastic and Its Environmental Impact

Polyethylene Terephthalate (PET) is a versatile and widely used plastic polymer known for its durability, clarity, and lightweight properties. It is commonly used in the production of beverage bottles, food containers, and packaging materials due to its excellent barrier properties and ability to withstand pressure.

While PET plastic offers numerous benefits in terms of convenience and functionality, its improper disposal poses significant environmental challenges. PET bottles often end up in landfills, where they can take hundreds of years to decompose, releasing harmful chemicals into the soil and water. Additionally, when littered or improperly disposed of, PET bottles can contribute to pollution in rivers, oceans, and other natural habitats.

The environmental impact of PET plastic extends beyond its physical presence in the environment. The production of PET plastic involves the extraction of fossil fuels and the consumption of energy, contributing to greenhouse gas emissions and exacerbating climate change. Furthermore, the manufacturing process generates waste and pollution, further compounding environmental degradation.

To mitigate the adverse environmental impact of PET plastic, PET recycling lines, including PET bottle recycling lines, PET bottle washing lines, and PET bottle crushing washing recycling lines, play a crucial role. These recycling systems provide an effective means of diverting PET bottles from landfills and transforming them into reusable materials.

PET bottle recycling lines utilize a combination of processes, including crushing, washing, and extrusion, to transform PET bottles into recycled material suitable for use in various applications. These lines are equipped with PET bottle crushing, washing, and recycling equipment, such as crushers, washers, and extruders, to efficiently process large volumes of PET waste.

By implementing PET recycling lines, businesses and communities can reduce their reliance on virgin plastic production, conserve natural resources, and minimize environmental pollution. Additionally, recycling PET plastic helps to create a circular economy where materials are reused and repurposed, contributing to long-term sustainability.

The Role of PET Recycling Line: Transform Waste to Valuable Resource

PET recycling lines are comprehensive systems designed to efficiently process PET plastic waste, particularly PET bottles, and transform them into valuable resources. These advanced recycling lines employ a series of interconnected processes, including sorting, crushing, washing, and pelletizing, to ensure the highest quality recycled PET output.

The primary function of PET recycling lines, such as PET bottle recycling lines, is to divert PET bottles from ending up in landfills or incineration facilities. Instead, these lines enable the collection, sorting, and processing of PET bottles, initiating their journey towards a new life as recycled materials. By doing so, PET recycling lines contribute significantly to waste reduction and alleviate the strain on already overwhelmed waste management systems.

PET bottle washing lines are an integral component of PET recycling lines, ensuring that the collected PET bottles are thoroughly cleaned before being transformed into recycled PET. This washing process involves the removal of contaminants such as labels, caps, and residual liquids, guaranteeing that the resulting recycled PET meets stringent quality standards.

The role of PET recycling lines, including PET bottle recycling lines and PET bottle washing lines, extends beyond waste reduction. These systems also promote resource conservation and environmental preservation. By recycling PET bottles, the demand for virgin plastic production decreases, alleviating the strain on natural resources, such as fossil fuels and petroleum. Additionally, PET recycling lines contribute to energy conservation, as the production of recycled PET requires less energy compared to producing new plastic from raw materials.

Moreover, the environmental benefits of PET recycling lines are substantial. By diverting PET bottles from landfills, these recycling lines help reduce greenhouse gas emissions associated with the decomposition of plastic waste. Additionally, they mitigate the pollution of ecosystems, including oceans and water bodies, as recycled PET materials reduce the likelihood of PET bottles ending up in these sensitive environments.

PET recycling lines also foster the circular economy. The recycled PET produced by these lines serves as a valuable resource for various industries, including packaging, and textiles. Recycled PET can be transformed into a wide range of products, including fibers for clothing, and bottles for non-food applications. This circular approach not only reduces the reliance on virgin plastic but also contributes to a more sustainable and resource-efficient economy.

By embracing the power of recycling plastics, we can make a significant difference in the fight against plastic pollution. With the PET bottle recycling line, we have the opportunity to turn waste plastics into treasure, contributing to a cleaner and greener future for all. So let’s join hands in this important endeavor and give those discarded plastic bottles a second chance at making a positive impact on our planet.

By harnessing the potential of plastic recycling, we hold the key to combating plastic pollution effectively. Through the implementation of PET bottle recycling lines, we empower ourselves to convert discarded plastics into valuable resources, thereby paving the way for a more sustainable future.

Components and Processes of a PET Recycling Line

A PET recycling line is a complex system comprised of various components and processes that work together to transform PET plastic waste into valuable recycled materials. In this chapter, we will explore the key components and processes involved in a PET recycling line, shedding light on their functions and the overall recycling process.

1. Conveyor Belt System

The conveyor belt system is a fundamental component of a PET recycling line. It facilitates the movement of PET waste from one stage to another, ensuring a continuous flow throughout the recycling process. This system efficiently transports PET bottles or flakes, enabling seamless integration of subsequent processes.

2. Sorting and Separation

The first step in the PET recycling line is sorting and separation. Advanced sorting technologies, such as optical scanners and infrared sensors, are employed to identify and separate different types of plastic. This ensures that only PET plastic enters the recycling line, enhancing the quality of the final recycled product.

3. Crushing and Shredding

After sorting, PET bottles or flakes undergo the crushing and shredding process. In this stage, the PET material is broken down into smaller pieces, increasing the efficiency of subsequent processes. Crushers and shredders break down the PET bottles into flakes or granules, helping reduce the size of PET waste, and facilitating the washing and cleaning processes while ensuring uniformity in particle size.

4. Washing and Cleaning

PET bottle washing lines or cleaning systems play a critical role in the PET recycling line. The washing process involves removing contaminants such as labels, caps, residue, and other impurities from the PET material. Various techniques, including friction, hot water, and chemical treatments, are employed to ensure thorough cleaning, resulting in high-quality recycled PET.

5. Drying

Following the washing and cleaning process, the PET material goes through a drying stage. Moisture removal is essential to prevent degradation and maintain the integrity of the recycled PET. Efficient drying systems, such as centrifugal dryers or hot air dryers, are utilized to achieve optimal moisture content in the PET flakes.

6. Extrusion

The dried PET flakes are then processed through extrusion, where they are melted and formed into pellets. Extruders apply heat and pressure to the PET flakes, transforming them into uniform pellets that can be used as raw material for manufacturing new products.

7. Pelletization

The final step in the PET recycling process is pelletization, where the molten PET is cooled and solidified into pellets. These pellets are then ready for use in various applications, such as the production of polyester fibers, textiles, and packaging materials.

8. Quality Control

Throughout the PET recycling line, quality control measures are implemented to ensure the production of high-quality recycled PET. This includes monitoring the IV value, color, and other physical properties of the recycled PET. Advanced testing equipment and quality control protocols are employed to meet stringent industry standards.

By incorporating these components and processes, a PET recycling line enables the efficient and effective transformation of PET plastic waste into valuable recycled PET materials. This not only reduces the environmental impact of PET waste but also contributes to the conservation of resources and the promotion of a circular economy.

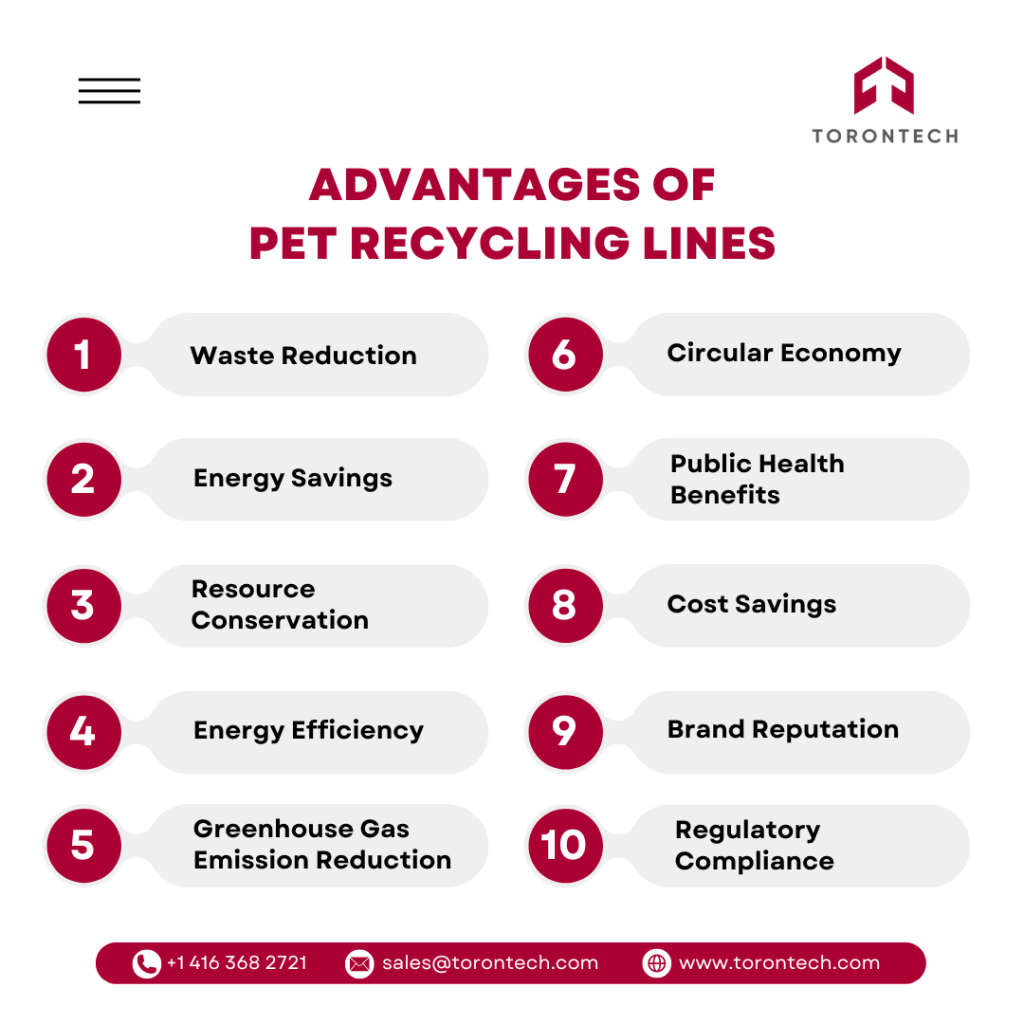

Importance and Benefits of PET Bottle Recycling

PET bottle recycling is a crucial process that addresses the environmental challenges posed by plastic waste while offering a multitude of benefits. Let’s delve into the importance and numerous advantages of PET bottle recycling, highlighting the role of PET recycling lines, including PET bottle recycling lines and PET bottle washing lines.

1. Waste Reduction

PET bottle recycling plays a crucial role in waste reduction efforts. By diverting PET bottles from landfills or incineration facilities, recycling lines, such as PET bottle recycling lines, ensure that these bottles are given a new life as valuable resources. This reduces the volume of plastic waste and alleviates the strain on waste management systems, leading to a cleaner and more sustainable environment.

2. Energy Savings

Recycling PET bottles requires less energy compared to producing virgin plastic. Recycling facilities equipped with PET recycling lines consume less energy in processing recycled materials, contributing to energy savings and reduced carbon emissions.

3. Resource Conservation

PET bottle recycling significantly contributes to resource conservation. By recycling PET bottles, the demand for virgin plastic production is reduced, conserving valuable resources such as fossil fuels and petroleum. PET recycling lines, including PET bottle recycling lines and PET bottle washing lines, facilitate the transformation of PET bottles into high-quality recycled PET materials, promoting the efficient use of resources and reducing reliance on new plastic production.

4. Energy Efficiency

PET bottle recycling lines, equipped with advanced technologies, enhance energy efficiency in the recycling process. The production of recycled PET requires less energy compared to manufacturing new plastic from raw materials. PET recycling lines optimize energy consumption at various stages, such as crushing, washing, drying, and extrusion, thereby reducing the carbon footprint associated with plastic production.

5. Greenhouse Gas Emission Reduction

Recycling PET bottles helps mitigate greenhouse gas emissions associated with plastic production and disposal. By recycling PET bottles instead of incinerating or landfilling them, we can reduce carbon dioxide emissions and combat climate change.

6. Circular Economy

PET bottle recycling lines contribute to the development of a circular economy. By processing PET bottles through recycling lines, the materials are transformed into recycled PET that serves as a valuable resource for multiple industries. Recycled PET can be used to produce new bottles, fibers for clothing, packaging strips, pellets, films, and other products. This circular approach minimizes waste, promotes resource efficiency, and fosters a sustainable economic model.

7. Public Health Benefits

Recycling PET bottles can have indirect public health benefits by reducing exposure to harmful chemicals and pollutants associated with plastic production and disposal. By recycling PET bottles, we can create cleaner and safer environments for communities to live and thrive in.

8. Cost Savings

Implementing PET bottle recycling can lead to cost savings for businesses and municipalities. Recycling PET bottles through PET recycling lines is often more cost-effective than landfilling or incinerating them, resulting in lower waste management costs and potential revenue generation from recycled materials.

9. Brand Reputation

Businesses that invest in PET bottle recycling demonstrate their commitment to environmental stewardship and corporate responsibility. By incorporating PET recycling into their operations, companies can enhance their brand reputation and attract environmentally conscious consumers, leading to increased market competitiveness and long-term success.

10. Regulatory Compliance

With increasing regulatory pressure to reduce plastic waste and promote recycling, investing in PET bottle recycling lines ensures compliance with environmental regulations and sustainability standards. By proactively addressing environmental concerns and implementing recycling initiatives, businesses can mitigate regulatory risks and maintain a positive reputation within their industries.

PET recycling lines play a critical role in facilitating the efficient processing of PET bottles and transforming them into valuable recycled PET materials. By embracing PET bottle recycling, we can collectively work towards a more sustainable future, mitigating the environmental impact of plastic waste and fostering a circular and responsible approach to resource utilization.

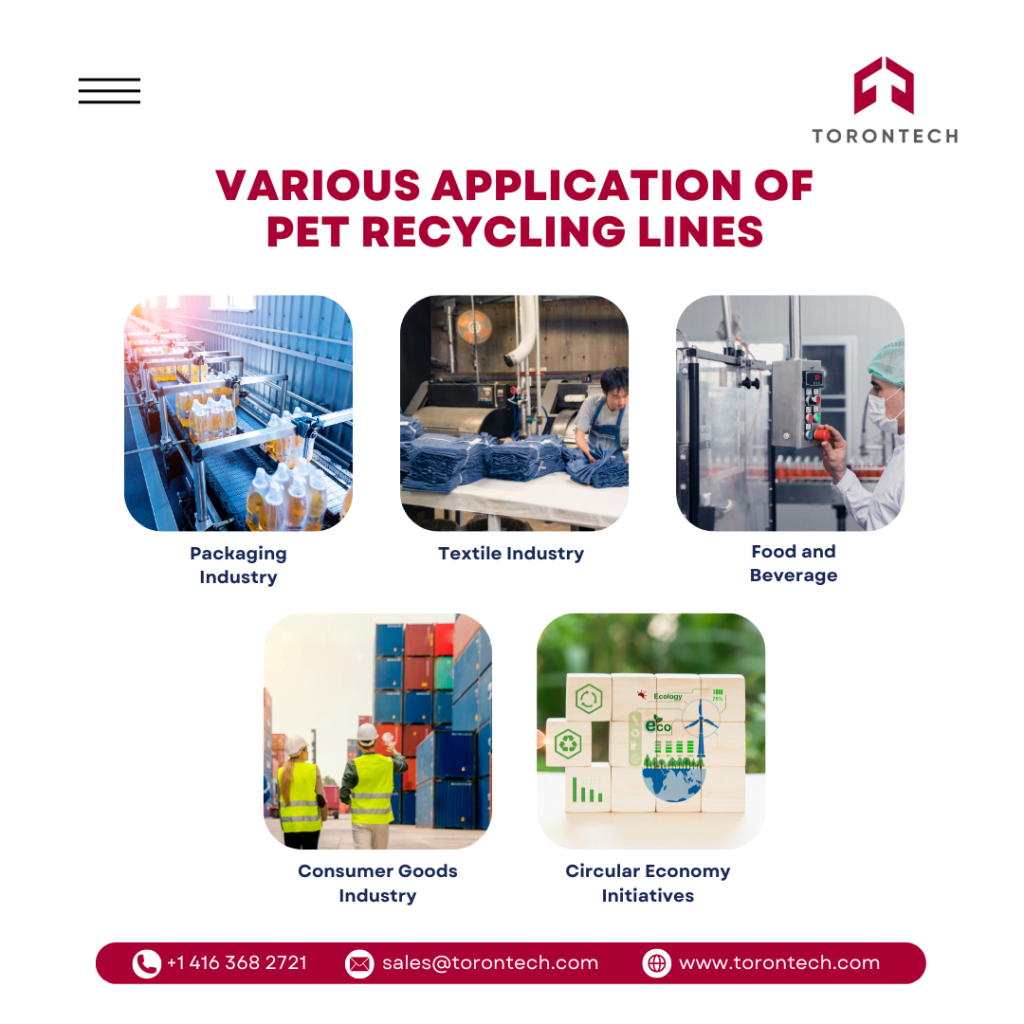

Applications of PET Recycling Lines for Various Industries

PET recycling lines play a crucial role in facilitating the recycling process in various industries. Let’s explore the diverse applications of PET recycling lines across different sectors.

1. Packaging Industry

PET recycling lines play a vital role in the packaging industry. The recycled PET produced by these lines can be used to manufacture new PET bottles, containers, and packaging materials. By incorporating recycled PET into their products, packaging companies reduce their reliance on virgin plastic, promote resource conservation, and contribute to a more sustainable packaging solution.

2. Textile Industry

PET recycling line is widely used in the textile industry to manufacture polyester fibers and fabrics. These recycled polyester textiles offer a sustainable alternative to conventional polyester, reducing the environmental footprint of clothing, upholstery, and other textile products.

3. Food and Beverage

In the food and beverage industry, recycled PET is used to manufacture food-grade packaging for beverages, snacks, and other food products. PET recycling lines ensure the cleanliness and safety of recycled PET material, meeting regulatory requirements for food contact applications.

4. Consumer Goods Industry

PET recycling lines contribute to the production of a wide range of consumer goods. These include household items, such as containers, utensils, and cleaning products, as well as recreational products, such as sports equipment and toys.

5. Circular Economy Initiatives

PET recycling lines play a vital role in promoting and supporting circular economy initiatives. By transforming PET waste into valuable recycled materials, these lines enable the closing of the loop, where recycled PET becomes a valuable resource for numerous industries. This fosters a sustainable and resource-efficient approach to manufacturing and consumption.

By supplying high-quality recycled PET material to various industries, PET recycling lines contribute to the circular economy and promote sustainable production practices. These applications demonstrate the versatility and value of recycled PET material in addressing the needs of diverse industries while reducing environmental impact.

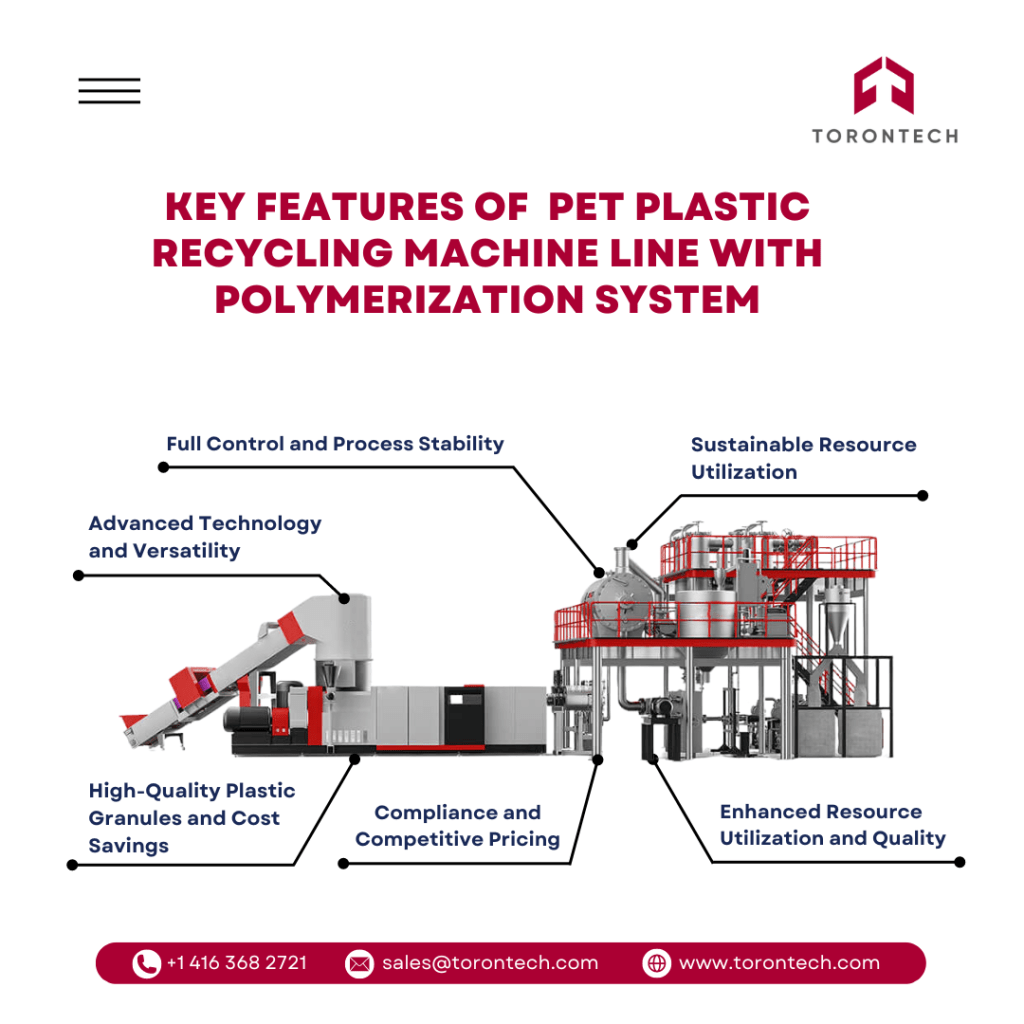

The Best PET Plastic Recycling Machine Line for Your Recycling Needs

When it comes to PET plastic recycling, efficiency, versatility, and product quality are paramount. Introducing PET Plastic Recycling Machine Line With Polymerization System from Torontech that sets the standard for excellence in PET recycling technology.

This machine incorporates cutting-edge Liquid State Polycondensation (LSP) technology, revolutionizing the PET recycling process by rapidly transforming PET scraps or flakes into valuable products. This innovative system offers unparalleled versatility, capable of recycling PET bottles into new bottles, producing fibers, PET fiber, packaging strips, pellets, or films. With full control over Intrinsic Viscosity (IV) value and guaranteed process stability, our machine ensures consistent, high-quality output every time.

This PET Plastic Recycling Machine Line With Polymerization System is designed to handle diverse materials with ease, yielding high-quality plastic granules while saving energy and reducing costs. Whether you are a PET recycling factory looking to enhance resource utilization or elevate resource quality, our Recycling Machine is the ideal choice for achieving your recycling goals.

Our PET Plastic Recycling Machine Line with polymerization system offers several benefits:

1. Advanced Technology and Versatility

Our PET Plastic Recycling Machine Line offers unparalleled versatility, capable of recycling PET bottles into new bottles, producing fibers, PET fiber, packaging strips, pellets, or films. This flexibility allows recycling factories to diversify their product offerings and meet the demands of various industries.

2. Full Control and Process Stability

One of the key advantages of the machine is its ability to provide full control over the Intrinsic Viscosity (IV) value of the recycled PET material. This control ensures consistent and reliable product quality, meeting the stringent requirements of different applications. The LSP system also guarantees process stability, minimizing downtime and optimizing production efficiency.

3. High-Quality Plastic Granules and Cost Savings

The PET Plastic Recycling Machine Line with the Polymerization System is designed to handle diverse materials and deliver high-quality plastic granules. By utilizing LSP technology, the system produces granules with excellent properties, suitable for a wide range of applications. Additionally, the LSP process offers energy savings and cost reduction, making it a financially viable solution for PET recycling facilities.

4. Enhanced Resource Utilization and Quality

This machine significantly enhances the quality of recycled PET materials, including fiber, bottle flakes, film, and Low IV polymer. This technology enables the production of high-grade PET fiber, packaging strips, pellets, and film, ensuring exceptional resource utilization and elevating the overall quality of recycled materials.

5. Sustainable Resource Utilization

PET recycling factories striving for sustainable practices and improved resource utilization will find our machine to be an ideal choice. This innovative machine line supports the circular economy by enabling the recycling of bottles into new bottles and fibers into new fibers. By promoting the reuse of PET materials, the LSP Series contributes to a more sustainable and environmentally friendly approach to plastic recycling.

6. Compliance and Competitive Pricing

When it comes to PET recycling solutions, quality and compliance are non-negotiable. The Recycling Machine Line from Torontech is designed to comply with international standards, ensuring reliability, safety, and performance. Moreover, our efficient supplier network enables us to offer fast delivery and the most competitive pricing, making our machine an unbeatable choice for PET recycling factories worldwide. So if you asked PET bottle recycling line price, our machine is the best solution.

PET Plastic Recycling Machine Line With Polymerization System from Torontech represents the pinnacle of PET plastic recycling technology, offering unparalleled efficiency, versatility, and quality. With its advanced features and innovative design, this machine line is poised to revolutionize the PET recycling industry, driving sustainability, and resource optimization for a greener future.

Conclusion

The journey through the world of PET Recycling Lines has shed light on the transformative power of this technology in addressing the global plastic waste crisis. From the innovative PET recycling lines to the cutting-edge LSP Series, it’s evident that these systems play a pivotal role in reshaping the future of recycling.

Throughout this exploration, we’ve uncovered the importance and benefits of PET bottle recycling, emphasizing the significant environmental and economic advantages it offers. By utilizing PET recycling lines, businesses and communities can reduce waste, conserve resources, and minimize environmental impact, all while achieving cost savings and enhancing product quality.

The versatility and efficiency of PET recycling lines, including the best PET recycling line offerings like the LSP Series, demonstrate the industry’s commitment to sustainability and innovation. With advanced technologies like Liquid State Polycondensation (LSP), PET recycling lines enable the production of high-quality recycled PET materials for a wide range of applications, from packaging to textiles, automotive parts, and beyond.

As we look towards the future, it’s clear that PET recycling lines will continue to play a vital role in promoting circular economy principles and driving positive change in the recycling industry. By investing in PET recycling lines and embracing sustainable practices, we can create a cleaner, greener future for generations to come.

Contact us today to learn more about the PET Plastic Recycling Machine Line and how it can transform your PET recycling operations. Together, let’s build a greener and more sustainable future for generations to come.