Bomb calorimeter analysis solves a growing challenge in the food industry: inconsistent or outdated caloric data. Relying only on calculated estimates or outdated Atwater values can lead to labeling inaccuracies, regulatory penalties, or lost consumer trust. This is especially risky when launching new products or reformulating for changing dietary trends.

Using this device gives food manufacturers a direct, science-backed way to measure the actual energy content of their products. With it, your team can ensure compliance, optimize formulations, and uphold the integrity of every label that reaches the shelf.

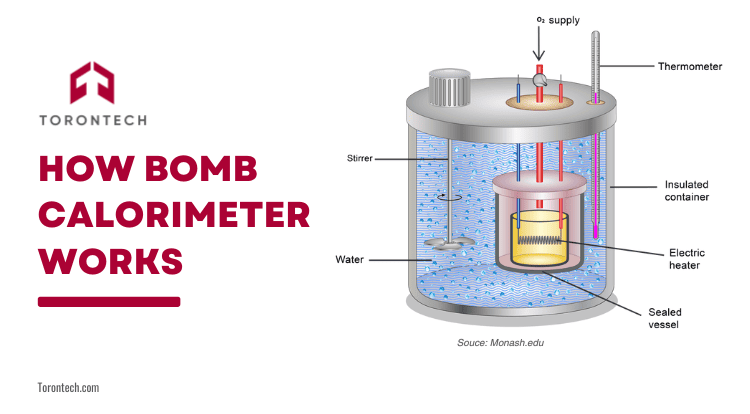

What Is a Bomb Calorimeter?

A bomb calorimeter is a laboratory instrument designed to determine the gross energy content of a food sample. It does this by combusting the sample in a controlled, oxygen-rich environment and measuring the heat released. Key Components:

- Combustion chamber (bomb): Where the food sample is burned.

- Water jacket: Surrounds the chamber to capture released heat.

- High-pressure oxygen: Ensures complete combustion.

- Thermometer and sensors: Measure water temperature changes with high precision.

The increase in water temperature, combined with the system’s known heat capacity, reveals exactly how many kilocalories or kilojoules are stored in that food item.

How Bomb Calorimeter Works: From Sample to Calorie Count

Understanding how a bomb calorimeter operates gives insight into its value for production teams, QA labs, and R&D departments:

- Sample Preparation: Foods are dried, homogenized, and weighed. This step ensures consistent combustion and minimizes water interference.

- Combustion Process: The sample is sealed in the bomb, filled with oxygen, and ignited. Complete combustion takes place in seconds.

- Heat Transfer: The generated heat raises the temperature of the surrounding water.

- Data Output: The system calculates energy content based on the water’s temperature increase, providing results in kcal/g or kJ/g.

This method delivers repeatable, precise caloric values, giving you hard data to support every label, claim, or formulation.

Why Bomb Calorimeter Matters for the Food Industry

When it comes to food energy analysis, the bomb calorimeter stands out as an indispensable tool. Its ability to deliver precise, consistent, and comprehensive data makes it a cornerstone of both research labs and production facilities. Here’s why it’s trusted across the food science landscape:

1. Unmatched Measurement Precision

Bomb calorimeters offer highly precise caloric readings, thanks to their sealed design and controlled combustion environment. Minimal heat loss ensures that results are not only repeatable but also scientifically robust — a requirement in regulatory audits and product validation processes.

2. Full-Spectrum Caloric Evaluation

This instrument captures the total chemical energy within a food sample, including contributions from proteins, fats, carbohydrates, and alcohol. For food labeling and dietary assessments, such complete energy profiling provides a more dependable foundation than estimated values alone.

3. Applicable to All Food Types

From powdered supplements and liquid beverages to raw grains and processed snacks, bomb calorimeters handle a diverse range of food matrices. This versatility supports both routine quality checks and complex formulation trials.

4. Critical for Label Accuracy and Compliance

Accurate energy data is central to nutrition labeling compliance. Bomb calorimeters help verify that the calories declared on packaging reflect the true energetic value of the product — reducing risk of mislabeling and strengthening brand credibility.

5. Valuable for Digestibility Studies

When combined with waste analysis, calorimetry helps assess the metabolizable energy available to the human body. This is especially useful for evaluating functional foods, high-fiber diets, or therapeutic nutrition products where digestibility varies significantly.

6. Supports Consistency and Innovation

Manufacturers use bomb calorimeters to monitor energy consistency across production batches and to guide product development. Whether adjusting an ingredient or launching a new formula, the tool delivers quick feedback on how changes affect caloric content.

7. Streamlined Operation and Standard Protocols

Modern systems are built with user-friendly interfaces and automation options, reducing training time and improving throughput. Standardized procedures also make it easier to compare results across different labs and testing periods.

8. Ideal for Benchmarking and Comparison

When comparing formulations, ingredients, or competitive products, a bomb calorimeter provides direct, quantifiable insights. This makes it invaluable for benchmarking during product positioning or reformulation planning.

Things to Consider Before Use

While powerful, the bomb calorimeter is only as accurate as your methods. Here are a few considerations to keep in mind:

- Standardized Sample Prep: Drying and homogenizing should follow consistent protocols. Variability can affect results.

- Understanding Gross vs. Usable Energy: Bomb calorimetry reports total energy, including portions the body may not digest.

- Complex Formulations: For multi-ingredient or processed foods, you may need additional methods or sample corrections.

Still, for direct measurement, few tools can match the accuracy and repeatability of this instrument.

Final Thoughts

The bomb calorimeter continues to be an essential tool for food manufacturers who prioritize precision, consistency, and regulatory compliance. Whether you’re enhancing product quality or ensuring nutritional accuracy, it delivers the reliable data your team depends on.

Explore the full Bomb Calorimeter by Torontechto see how our solutions can support your operations. For more details or tailored recommendations, contact us — we’re here to help you move forward with confidence.