Color plays a critical role in perception, branding, and product quality. But as subjective as it seems to our eyes, color measurement doesn’t have to rely on guesswork. That’s where the color spectrophotometer comes in, a scientific tool that helps industries translate color into data that can be measured, analyzed, and controlled.

Whether you’re in the industry of paints, plastics, textiles, or cosmetics, color measurement by spectrophotometer ensures that every hue meets expectations, batch after batch.

What Is a Color Spectrophotometer?

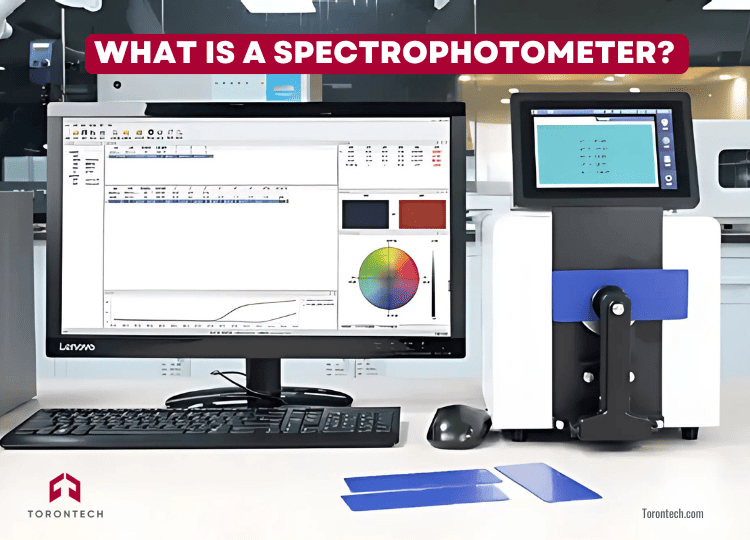

A color spectrophotometer is a scientific instrument used to evaluate and quantify color by measuring how a material interacts with light. It captures the amount of light reflected or transmitted across the visible spectrum and translates it into numerical color data.

Unlike the human eye, which is influenced by lighting and surroundings, this device provides objective and repeatable data that forms the foundation of modern color control programs.

When used as part of a color control process, it helps design teams, manufacturers, and quality assurance professionals work from a common language, ensuring visual consistency no matter where or how a product is made.

From paint color matching to product packaging, spectrophotometer color analysis helps maintain color integrity throughout the supply chain.

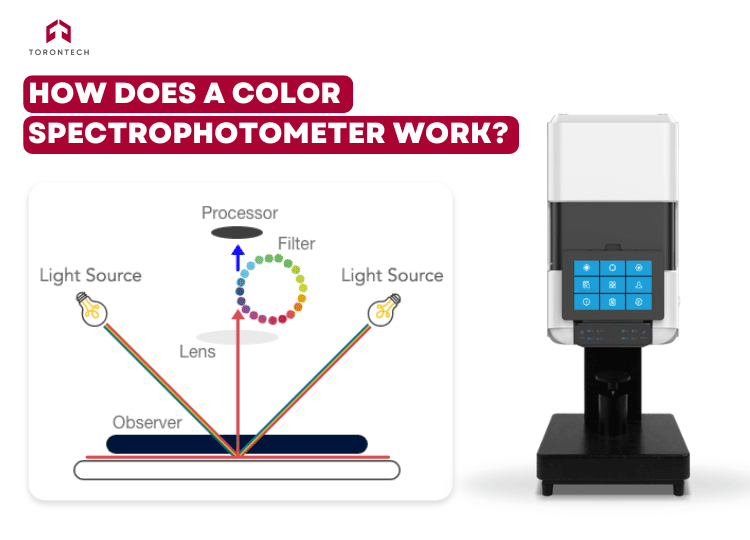

How Does a Color Spectrophotometer Work?

Understanding how a color spectrophotometer works begins with the concept of light behavior. Every surface reflects or absorbs light in its own unique way. The spectrophotometer uses this principle to capture a color’s “signature” by measuring light at specific wavelengths.

Here’s a simplified breakdown of its components:

- Light Source: Illuminates the sample

- Monochromator: Isolates specific wavelengths of light

- Sample Holder: Secures the object for measurement

- Detector: Records how much light is absorbed, transmitted, or reflected

Depending on the device’s configuration, the spectrophotometer may measure reflected light (for opaque materials) or transmitted light (for transparent samples like films or liquids).

This process produces a spectral reflectance curve, often referred to as the color’s “fingerprint.” It is used in everything from quality control to spectrophotometer color matching and formulation.

Spectrophotometer Color Measurement in Real Applications

A color measurement spectrophotometer isn’t just for scientists, it’s a trusted ally across industries:

- Paint & Coatings: A spectrophotometer for paint color matching ensures each gallon matches the swatch, no matter the production line or location.

- Textiles: From fabric rolls to apparel dyeing, it maintains consistent tones batch to batch.

- Plastics & Packaging: Helps ensure branding colors are always on point.

- Automotive: Used in both multi-angle spectrophotometers and standard models to measure effect pigments like metallics and pearls.

Whether you’re using a data color spectrophotometer in the lab or a portable spectrophotometer for color measurement on the shop floor, the goal is the same: accuracy, repeatability, and efficiency.

Different Types of Color Spectrophotometers

Color spectrophotometers come in different geometries and configurations depending on what and where you’re measuring.

1. 0º:45º or 45º:0º Spectrophotometers

This is one of the most commonly used types. It captures reflected light at a fixed angle, closely simulating how the human eye perceives color. Ideal for spectrophotometer color analysis on smooth, matte surfaces.

2. Sphere (Integrating) Spectrophotometers

Perfect for measuring glossy, textured, or curved surfaces like plastics, textiles, or metallic coatings. Sphere instruments scatter light uniformly, simulating diffuse illumination to mimic real-world lighting conditions. Some even include UV capability to handle materials affected by ultraviolet light.

3. Multi-Angle Spectrophotometers

If you’re working with effect finishes (think pearlescent car paint or shimmering nail polish), this is your go-to. These devices measure color at multiple viewing angles, critical for spectrophotometer for color matching in surfaces that shift color with perspective.

Portable vs. Benchtop vs. Inline Spectrophotometers

You can choose your tool based on your workflow:

- Handheld color spectrophotometer: Lightweight and mobile. A portable color spectrophotometer lets you bring the device to the sample. Ideal for on-site inspections or tight production areas.

- Benchtop spectrophotometer: Offers the highest precision. Best used in labs or centralized quality control for formulation and specification.

- Inline spectrophotometer: Mounted directly on production lines. These offer real-time monitoring, instantly alerting operators to any deviation in color specs, minimizing waste and rework.

How to Read Color Spectrophotometer Results

Once you’ve captured a color sample, the spectrophotometer translates it into measurable values:

- L*: Lightness

- a*: Red-Green axis

- b*: Yellow-Blue axis

- ΔE (Delta E): Total color difference from a target or standard

Understanding how to read color spectrophotometer results allows you to detect even subtle shifts that might not be visible to the naked eye. This data is often visualized via a spectrophotometer color chart or mapped onto a spectrophotometer color wheel to assist in decision-making.

It’s also possible to analyze complementary colors through spectrophotometric data, which is helpful when designing color harmonies or managing color contrast in packaging and branding.

Why Use a Spectrophotometer for Color Measurement?

Implementing a color measurement spectrophotometer into your workflow reduces variability and human error. Here are some tangible benefits:

- Objective, repeatable measurements

- Cross-location consistency for global supply chains

- Compliance with ISO, ASTM, and industry-specific standards

- Improved production efficiency and reduced rework

- Faster time-to-market through early color validation

By removing subjectivity from the process, you can ensure your colors align with design intent, every time.

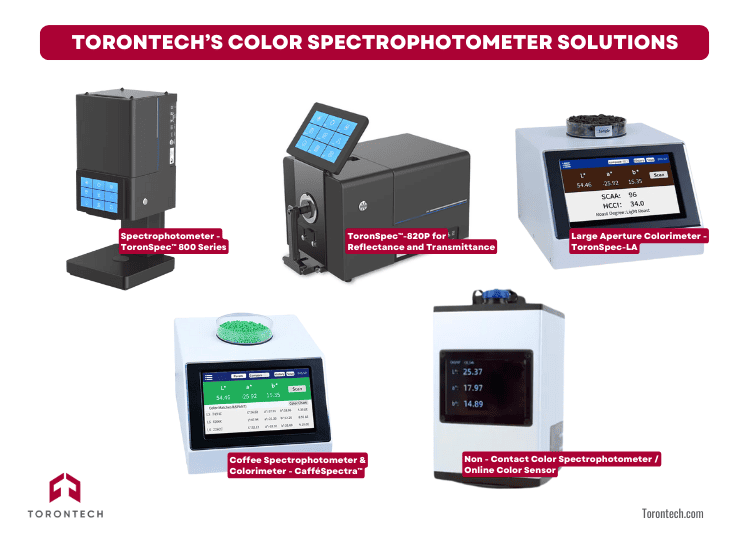

Explore ToronTech’s Professional Color Spectrophotometer Solutions

If you’re looking to implement or upgrade your color measurement system, ToronTech offers a versatile and high-performance range of color spectrophotometers designed to meet the evolving demands of color quality control across multiple industries.

Whether your application requires laboratory-grade accuracy or portable flexibility, our instruments deliver precise, reliable, and consistent color data that aligns with international standards.

1. Portable Color Spectrophotometer – ToronSpec™ 700D

Perfect for on-the-go professionals, the ToronSpec™ 700D is a handheld color spectrophotometer built for portability without compromising accuracy. Ideal for in-field inspections, quality checks on the production line, or remote site audits. Its ergonomic design and intuitive interface make color matching and analysis quick and user-friendly.

2. Benchtop Color Spectrophotometer & Colorimeter

Engineered for high-precision applications, our benchtop spectrophotometer delivers consistent and reproducible results across a wide range of materials, from plastics to textiles. Ideal for formulation, color approval, and compliance testing in R&D and QA labs.

3. High-Precision Benchtop Color Spectrophotometer

When accuracy is non-negotiable, this advanced high-precision spectrophotometer offers superior spectral resolution and repeatability. It’s designed for industries where even the smallest color variation is unacceptable. Perfect for paints, coatings, cosmetics, and specialty finishes.

4. ToronSpec™ 820P Benchtop Spectrophotometer (Reflectance & Transmittance)

The ToronSpec™ 820P is a versatile dual-mode instrument capable of both reflectance and transmittance measurements. It’s ideally suited for color analysis of transparent and opaque materials such as films, liquids, glasses, and coated surfaces—streamlining lab workflows with one all-in-one unit.

5. Non-Contact Color Spectrophotometer – Online Color Sensor

Designed for continuous, real-time color control, our non-contact spectrophotometer integrates seamlessly into production lines for inline color measurement. It monitors color accuracy during manufacturing and immediately flags deviations, reducing waste and improving yield.

Final Thoughts

Color is no longer just about perception, it’s about precision. Whether you’re developing a new product, checking batch consistency, or troubleshooting mismatched colors, a color spectrophotometer is the key to confident color decisions.

From portable spectrophotometers for color measurement on the go, to advanced multi-angle instruments for specialty finishes, these tools make spectrophotometer color measurement accessible, accurate, and essential.