A cryostat is a specialized device designed to maintain very low temperatures for material testing purposes. If you’re searching for equipment to conduct Charpy impact testing at sub-zero temperatures, you might encounter both “low temperature cooling chamber” and “cryostat” terminology. These terms are often used interchangeably in materials testing applications, though they feature key differences worth understanding.

What Is a Cryostat for Impact Testing?

Cryostats used in material impact testing provide controlled low-temperature environments to evaluate how materials perform under cold or cryogenic conditions. These specialized chambers maintain temperatures ranging from ambient down to -70°C or lower, allowing engineers to assess critical material properties including:

- Impact resistance at sub-zero temperatures

- Ductile-to-brittle transition behavior

- Fracture toughness across temperature ranges

- Material embrittlement at low temperatures

- Energy absorption capacity during rapid loading

The equipment precisely controls specimen temperature while facilitating quick transfer to testing apparatus, ensuring accurate results that reflect true material performance under cold conditions.

The Relationship Between Cryostats and Low Temperature Cooling Chambers

While traditional laboratory cryostats might maintain specimens at extremely low temperatures (often using liquid nitrogen or helium), specialized impact testing variants like low temperature cooling chambers offer targeted functionality specific to standardized testing procedures:

- Temperature range optimization for material transition point identification

- Specimen accommodation designed specifically for standard Charpy or Izod geometries

- Integration capabilities with impact testing machines

- Controlled thermal conditioning meeting international testing standards

- Safety features appropriate for materials testing laboratories

Many materials testing professionals use both terms interchangeably when referring to temperature-controlled environments for impact specimens.

Impact Testing Fundamentals: Charpy and Izod Methods

Understanding impact testing helps clarify why temperature-controlled environments are essential:

1. Charpy V-Notch Testing

The Charpy test measures a material’s resistance to impact fracture using a standardized pendulum hammer striking a notched specimen. The specimen rests horizontally on supports with the notch centered away from the striking point. The energy absorbed during fracture indicates material toughness.

2. Izod Impact Testing

Similar to Charpy but with different specimen orientation, the Izod test secures specimens vertically in a vise with the notch facing the striking pendulum. As described in D.T. Eash’s paper “A Cryostat for Izod Impact Testing,” specialized equipment ensures consistent temperature control from conditioning through testing.

Both testing methodologies require precise temperature control because many materials—particularly metals and some polymers—undergo significant property changes at low temperatures:

- Steel may exhibit ductile-to-brittle transition

- Polymers can experience glass transitions

- Composites might show altered fracture mechanisms

- Welded joints often demonstrate modified failure modes

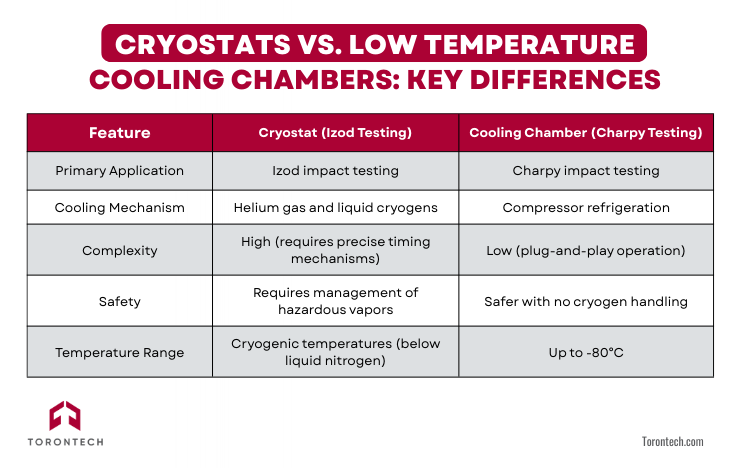

Cryostats vs. Low Temperature Cooling Chambers: Key Differences

Traditional cryostats and specialized cooling chambers serve similar purposes but differ in design and application:

Traditional Cryostats (Like Those for Izod Testing)

- Use liquid cryogens (nitrogen, helium) for extreme cold

- Feature complex specimen transfer mechanisms

- Incorporate sophisticated timing systems

- Require careful handling of hazardous vapors

- Excel at achieving temperatures below -100°C

As documented in research by D.T. Eash at Los Alamos Laboratory, historical cryostats for Izod testing used innovative helium gas systems to propel specimens from cooling chambers to testing positions with precise millisecond timing.

Modern Cooling Chambers (For Charpy Testing)

- Employ refrigeration-based cooling (typically to -70°C or -80°C)

- Offer simpler “plug-and-play” operation

- Eliminate the need for cryogenic fluids

- Provide user-friendly digital controls

- Maintain compliance with ASTM E23 and ISO 148-1 standards

For most standard Charpy impact testing applications, a dedicated cooling chamber offers the ideal balance of performance, safety, and ease of use.

Why Temperature Control Matters in Your Impact Testing

When you conduct impact tests, precise temperature control directly affects your results. Many materials undergo significant property changes at low temperatures:

- Steels transition from ductile to brittle behavior

- Polymers experience altered mechanical responses

- Welded joints demonstrate modified failure modes

- Composites show varied delamination patterns

Without proper temperature conditioning and control during specimen transfer, your test results may not accurately reflect real-world material performance in cold environments.

Applications Where Your Testing Equipment Makes a Difference

Your choice of temperature control equipment impacts testing across numerous industries:

- Oil and Gas: Ensuring pipeline materials withstand arctic conditions

- Aerospace: Qualifying components for high-altitude operations

- Automotive: Validating safety-critical parts for winter conditions

- Infrastructure: Certifying structural materials for cold-climate bridges

- Energy: Verifying power generation equipment durability

For each application, your ability to maintain precise temperature control from conditioning through testing directly influences material selection decisions and safety margins.

Selecting the Right Equipment for Your Testing Needs

When evaluating cryostats or cooling chambers for your laboratory, consider these factors:

- Temperature Range Requirements: Match to your specific testing protocols

- Testing Standards Compliance: Ensure compatibility with relevant ASTM or ISO standards

- Laboratory Safety Considerations: Assess your facility’s capability to handle cryogens

- Operational Complexity: Consider staff training and maintenance requirements

- Budget Constraints: Balance initial costs against long-term operational expenses

For most materials testing laboratories conducting standard Charpy impact tests, a dedicated cooling chamber provides the optimal combination of performance, safety, and value.

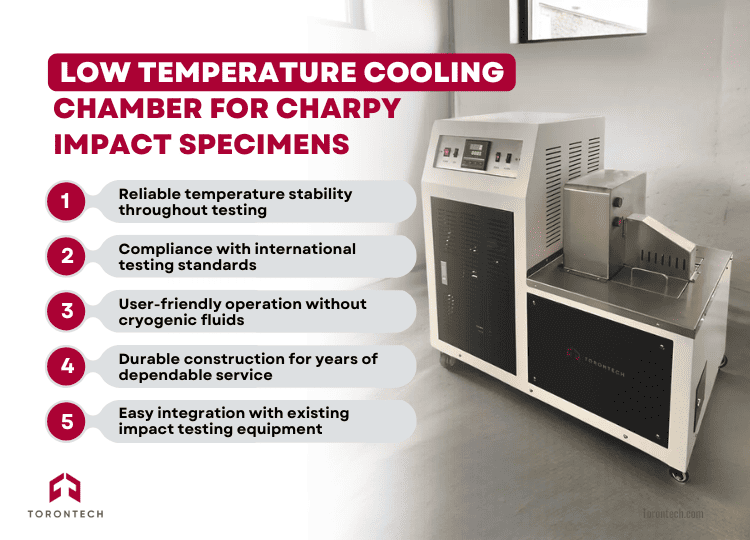

Enhance Your Materials Testing Capabilities

Torontech’s Low Temperature Cooling Chamber for Charpy Impact Specimens offers the precision temperature control you need for accurate materials characterization from ambient down to -70°C. This purpose-built system provides:

- Reliable temperature stability throughout testing

- Compliance with international testing standards

- User-friendly operation without cryogenic fluids

- Durable construction for years of dependable service

- Easy integration with existing impact testing equipment

Whether you’re performing quality control testing, research and development, or material qualification for critical applications, this specialized cooling chamber delivers the temperature control precision your protocols demand. Contact us for more information or if you have any question!