Densimeter is essential tools for measuring the density of various substances across various industries and scientific fields. It serves as a vital parameter for quality control, research, and development. Whether you work in the jewelry industry, pharmaceuticals, or deal with solids and liquids, understanding the principle and applications of densimeters is essential.

In this blog post, we will explore the fundamentals of densimeters, diverse applications, and key considerations for their use. By the end, you will have a solid understanding of how this tool contribute to density measurement and their potential benefits in your specific industry or field.

The Fundamental of Densimeter

What exactly is a densimeter, and why do these instruments hold such significance across diverse fields? Let’s delve into the definition and explore the importance of instrument in various industries.

A. Definition of Densimeter

A densimeter, also known as a density meter, is a sophisticated instrument specifically designed for measuring the density of substances. Density is defined as the mass of a substance per unit volume, such as kilograms per cubic meter (kg/m³) or pounds per cubic foot (lb/ft³). It serves as a fundamental property that offers valuable insights into composition, purity, and physical characteristics.

A densimeter is used to measure the density of various materials, including liquids, solids, and gases. Densimeters find extensive use across industries that demand precise density measurements. From the jewelry industry to pharmaceuticals, chemical engineering, and research laboratories, these versatile instruments provide a non-destructive and efficient method to determine density.

B. Working Principle of Densimeter

Density meters (densimeters) operate on the fundamental principle of relating the density of a substance to its mass and volume. The core of a densimeter is a sensor or mechanism that detects the density of the substance by measuring its mass or volume, or both, in a specific volume or mass of a fluid. The relationship between the mass and volume of the substance is used to calculate the density.

The most common working principle of densimeters is based on Archimedes’ principle, which states that an object submerged in a fluid experiences an upward buoyant force equal to the weight of the fluid displaced by the object. Applying this principle, densimeters measure the buoyant force to calculate the density of the substance.

C. How Densimeter Measure Density

Densimeters measure density by comparing the buoyant force experienced by the sensor in the substance being measured with the buoyant force in a reference fluid, typically water. The difference in the buoyant forces is directly proportional to the density of the substance.

A densimeter generally comprises a measurement chamber, a sensor, and electronic circuits to process the sensor signal and calculate the density. The measurement chamber is the part of the densimeter that holds the substance and the reference fluid. The sensor is usually a hollow body or a float that can move vertically in the measurement chamber in response to the buoyant force experienced.

The sensor’s movement in the measurement chamber is detected and converted into an electrical signal. The electronic circuits process the sensor signal to calculate the density of the substance based on the difference in the buoyant forces in the substance and the reference fluid.

D. Types of Densimeters

Two primary types of densimeters are digital and electronic:

1. Digital Densimeters

Digital densimeters are self-contained, portable, and battery-operated instruments. They are equipped with a built-in microprocessor and display, which facilitates the direct reading of density values. Digital densimeters often feature temperature compensation and offer a high degree of accuracy and precision.

2. Electronic Densimeters

Electronic densimeters are more advanced, featuring sophisticated electronics, sensors, and software algorithms. They typically provide higher accuracy and precision compared to digital densimeters. Electronic densimeters can be configured to interface with other devices, such as computers, via data communication ports, allowing for easy data collection and analysis.

Both digital and electronic densimeters may use different measurement methods, such as buoyancy, vibration, and oscillation, depending on the application and required accuracy.

How to Use a Densimeter?

Now that we understand the fundamentals behind densimeters and their various types, let’s delve into the practical aspects of using these instruments. This chapter will guide you through the steps involved in using a densimeter, ensuring accurate and reliable density measurements.

A. Preparing the Densimeter

1. Select The Appropriate Densimeter

Choose a densimeter suitable for your specific application, considering factors such as the type of substance, temperature range, and required accuracy.

2. Calibrate The Instrument

Before taking measurements, calibrate the densimeter using a reference material with a known density, typically water. This step will ensure accurate and precise readings.

B. Measuring the Density of a Substance

1. Set the Densimeter to the Correct Measurement Unit

Ensure the densimeter is configured to display the desired density unit, such as grams per milliliter (g/mL) or kilograms per cubic meter (kg/m³).

2. Adjust the Temperature (If Necessary)

Some densimeters include temperature compensation features, ensuring accurate measurements even in varying temperatures. Adjust the temperature setting, if available, to match the temperature of the substance being measured.

3. Immerse the Densimeter

Carefully immerse the densimeter in the substance to be measured. Make sure the entire sensing element, such as the bulb or float, is submerged.

4. Obtain the Density Reading

Wait for the densimeter to stabilize, indicating that the substance has displaced the appropriate amount of fluid. Record the density reading displayed on the densimeter.

C. Interpreting Density Measurements

- Understand the units of measurement displayed by the densimeter (e.g., g/cm³, kg/m³, specific gravity).

- Compare the measured density to known values or industry standards to determine the quality, purity, or composition of the sample.

- Utilize density measurements in calculations or analyses related to the specific application or industry.

D. Maintaining and Troubleshooting

1. Clean the Densimeter

After each use, clean the densimeter with a suitable cleaning solution and dry thoroughly to prevent contamination and ensure accurate readings in subsequent measurements.

2. Store the Densimeter Properly

Keep the densimeter in a secure and dry location, avoiding exposure to extreme temperatures, moisture, or chemicals.

3. Check for Accuracy

Periodically test the densimeter against a reference material to ensure continued accuracy and recalibrate, if necessary.

4. Inspect for Damage

Regularly inspect the densimeter for signs of wear or damage, and repair or replace components as needed to maintain optimal performance.

By following these steps and understanding the best practices for using densimeters, you can ensure accurate and reliable density measurements, which are critical for a wide range of applications, from quality control to research and development.

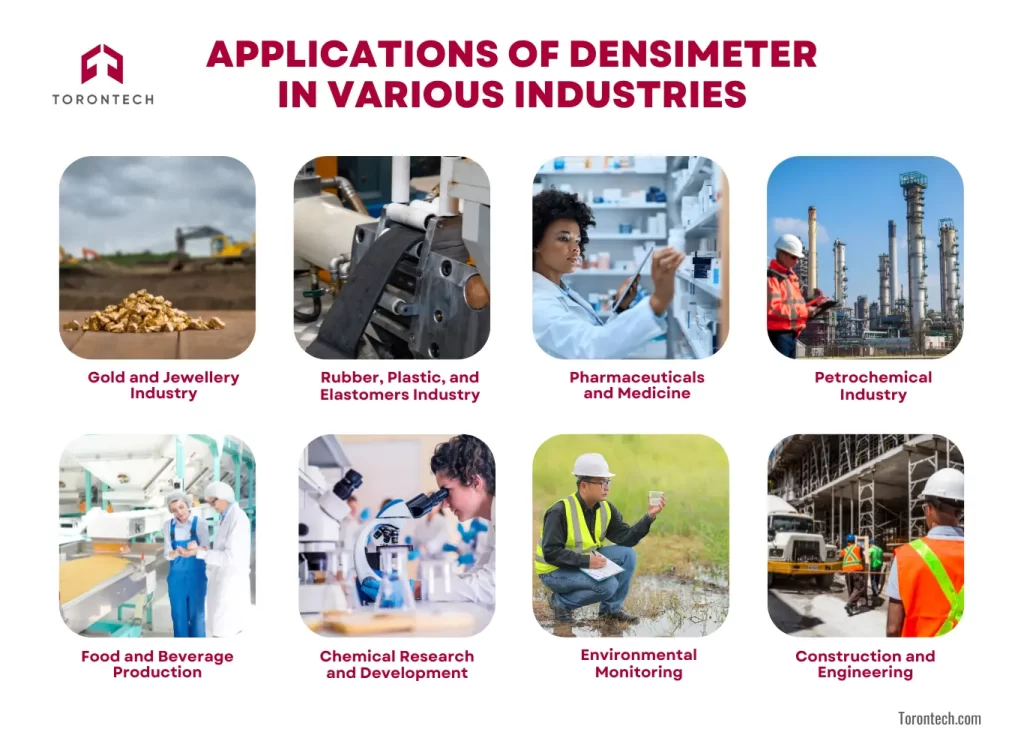

Applications of Densimeters

Densimeters are versatile instruments that find applications across a wide range of industries and scientific disciplines. In this chapter, we will explore the diverse uses of densimeters in different sectors, highlighting their importance in quality control, process optimization, and research.

1. Densimeter for Gold Testing

In the precious metals industry, densimeters play a crucial role in the analysis and authentication of gold. By accurately measuring the density of gold samples, densimeters can help determine the purity and composition of the metal. This information is essential for ensuring the quality and authenticity of gold jewelry, coins, and bullion, making densimeters an indispensable tool for gold testing and verification.

2. Densimeter for Solid Materials

Densimeters are not limited to liquids, this instrument is also widely used for the characterization of solid materials. In the fields of rubber, plastics, and elastomers, densimeters help determine the density and composition of these materials, which is crucial for quality control and product development.

Similarly, in powder metallurgy and ceramic manufacturing, densimeters are employed to measure the density of powders and pressed parts, ensuring consistent quality and performance.

3. Densimeter for Liquids

The traditional application of densimeters lies in the measurement of liquid density. Industries such as petrochemicals, pharmaceuticals, and food and beverage production rely on densimeters to monitor the density of their products. This information is vital for ensuring compliance with industry standards, optimizing production processes, and maintaining the desired quality and consistency of the final products.

4. Specialized Applications in Various Industries

The importance of densimeters extends beyond mere density measurements, this instrument finds applications in a variety of specialized fields.

a. Gold and Jewellery Industry

Densimeters can solve the problem of ensuring the authenticity and purity of gold in jewelry production. By measuring the density of a gold sample, jewelers can verify its karat value, which guarantees the jewelry’s quality and adherence to industry standards.

b. Rubber and Plastic Industry

Densimeter address the challenge of maintaining consistent quality and desired physical properties in the rubber and plastic industry. They monitor material consistency, control production processes, develop new materials, and identify material defects. Density measurements help ensure the production of high-quality, reliable rubber and plastic products.

c. Pharmaceuticals and Medicine

In the pharmaceutical and medical industries, densimeters are essential for ensuring the quality and consistency of liquid medications, injectables, and other formulations. These instruments help verify adherence to strict regulatory standards and can even aid in the diagnosis and monitoring of certain medical conditions, such as assessing kidney function through urine density measurements.

d. Petrochemical Industry

Densimeter play a vital role in the petrochemical industry, where they are used to measure the density of crude oil, petroleum products, and various chemical compounds. This information is crucial for determining composition, purity, and energy content, as well as ensuring compliance with industry specifications and assessing fuel quality.

e. Food and Beverage Production

Food and beverage production heavily relies on densimeters to monitor the fermentation process of alcoholic beverages like beer, wine, and spirits. By measuring the density changes, producers can accurately estimate alcohol content and maintain consistent taste and quality. Densimeters are also utilized to measure the density of other food products, such as syrups, sauces, and dairy items.

f. Chemical Research and Development

In chemical research and development laboratories, densimeters are indispensable tools for characterizing substances, determining their purity, and studying their physical properties. These measurements provide valuable insights that aid in the development of new materials, polymers, and formulations.

g. Environmental Monitoring

Densimeters play a crucial role in environmental monitoring, where they are used to measure the density of water samples to assess parameters like salinity, pollution levels, and overall water quality. They are also employed in the analysis of soil density, contributing to soil classification and fertility assessments.

h. Construction and Engineering

Construction and engineering industries rely on densimeters to assess the density and compaction of materials like concrete, asphalt, soil, and aggregates. By ensuring the proper density and compaction of these materials, densimeters contribute to the structural integrity and durability of buildings, roads, and infrastructure projects.

Densimeters have become indispensable tools in modern industry and research, serving as essential instruments for the characterization and quality control of a wide range of materials, from precious metals to solid and liquid substances.

Conclusion

Densimeters have become indispensable tools across a wide range of industries, from pharmaceuticals and petrochemicals to food production and environmental monitoring. These versatile instruments enable the precise measurement of liquid, solid, and even gaseous densities, providing crucial insights that drive quality control, process optimization, and scientific advancements.

In the field of gold testing, densimeters serve as indispensable tools, allowing for the verification of gold purity and authenticity. Beyond precious metals, these instruments find applications in the assessment of solid materials, such as rubber, plastics, elastomers, powder metallurgy, and ceramics. With measuring the density of these substances, manufacturers can maintain consistent quality, enhance product performance, and develop innovative materials.

Densimeters also find extensive use in the analysis of liquids, from general liquids to high-viscosity fluids, suspensions, emulsions, and colloidal dispersions. These advanced densimeters can accurately measure the density of a wide range of liquid materials, providing valuable insights into their composition, concentration, and purity.

Ready to explore the range of densimeters available? Visit our website to find the perfect instrument for your application!