The fast-paced and interconnected nature of our modern world relies heavily on fiber optic cables to establish dependable communication networks. To guarantee the smooth transmission of data, it becomes imperative to assess the quality and performance of these cables through the utilization of specialized intrument like a fibre optic cable testing.

These testing instruments are designed to evaluate the quality, durability, and tensile strength of fiber optic cables, safeguarding the integrity of telecommunications networks and data centers. In this blog post, we will explore the fundamentals and advantages of fiber optic cable testing, including how to effectively test a fiber optic cable.

Understanding Fiber Optic Cable Testing Equipment

Optical cable testing machines are specialized devices designed to test indoor optical cables. These machines can apply controlled tensile forces on the cables, allowing technicians to assess their tensile strength and durability. Additionally, optical cable testing machines feature an extensometer, which accurately measures the cable elongation when subjected to tension.

The primary purpose of these machines is to evaluate the performance and reliability of indoor optical cables under different levels of tension. By applying controlled tensile forces, technicians can assess how the cables withstand stress and determine their tensile strength. This information is vital for ensuring that the cables can endure the rigors of installation and operation without experiencing structural damage or signal loss.

The inclusion of an extensometer in optical cable testing machines is crucial for precise measurements of cable elongation. As tension is applied to the cable, the extensometer measures the changes in its length, providing valuable data on the cable’s flexibility and elasticity. This data helps technicians understand the cable’s behavior under tension and ensures it meets the necessary standards and specifications.

This instrument is also important to evaluate the cable’s tensile strength. The tensile strength of Fiber Optic Cables refers to the maximum amount of pulling force a cable can withstand without breaking or suffering permanent damage. Measuring and understanding the tensile strength of fiber optic cables is crucial for ensuring their durability and ability to withstand tension and stress during installation and operation.

Overall, optical cable testing machines play a pivotal role in evaluating indoor optical cables’ performance and tensile strength. By applying controlled forces and measuring cable elongation, technicians can ensure the cables’ reliability and durability, enabling seamless and uninterrupted data transmission in indoor environments.

Standard Testing Methods

The method used in the Optical Fiber Cable Tensile Testing Machine – Indoor Cable follows the IEC-60794-1-2 Method E1. The international standard governs this method and aims to measure the tensile strength of fiber optic cables.

The IEC standards are widely recognized as the best practices in the global fiber optic cable industry. Method E1 provides a standardized procedure for testing the tensile strength of fiber optic cables, ensuring consistent test results across various laboratories and testing locations. It also generates highly accurate data regarding the tensile strength of fiber optic cables, which is crucial for assessing the integrity and performance in various applications.

One of the advantages of this method is its strict documentation requirements, enabling users and fiber optic cable manufacturers to track test results precisely. This is essential for quality management and cable performance evaluation. As a part of an international standard, the E1 method is used by many companies and organizations worldwide, facilitating the comparison and exchange of information among stakeholders in the fiber optic cable industry.

The Importance of Testing Fiber Optic Cables

The importance of testing fiber optic cables cannot be overstated when it comes to ensuring communication networks’ reliability, performance, and longevity. Proper testing procedures and equipment are essential for guaranteeing that fiber optic cables meet the required standards and specifications. Here, we will delve into the significance of testing fiber optic cables and highlight the key reasons why it is crucial.

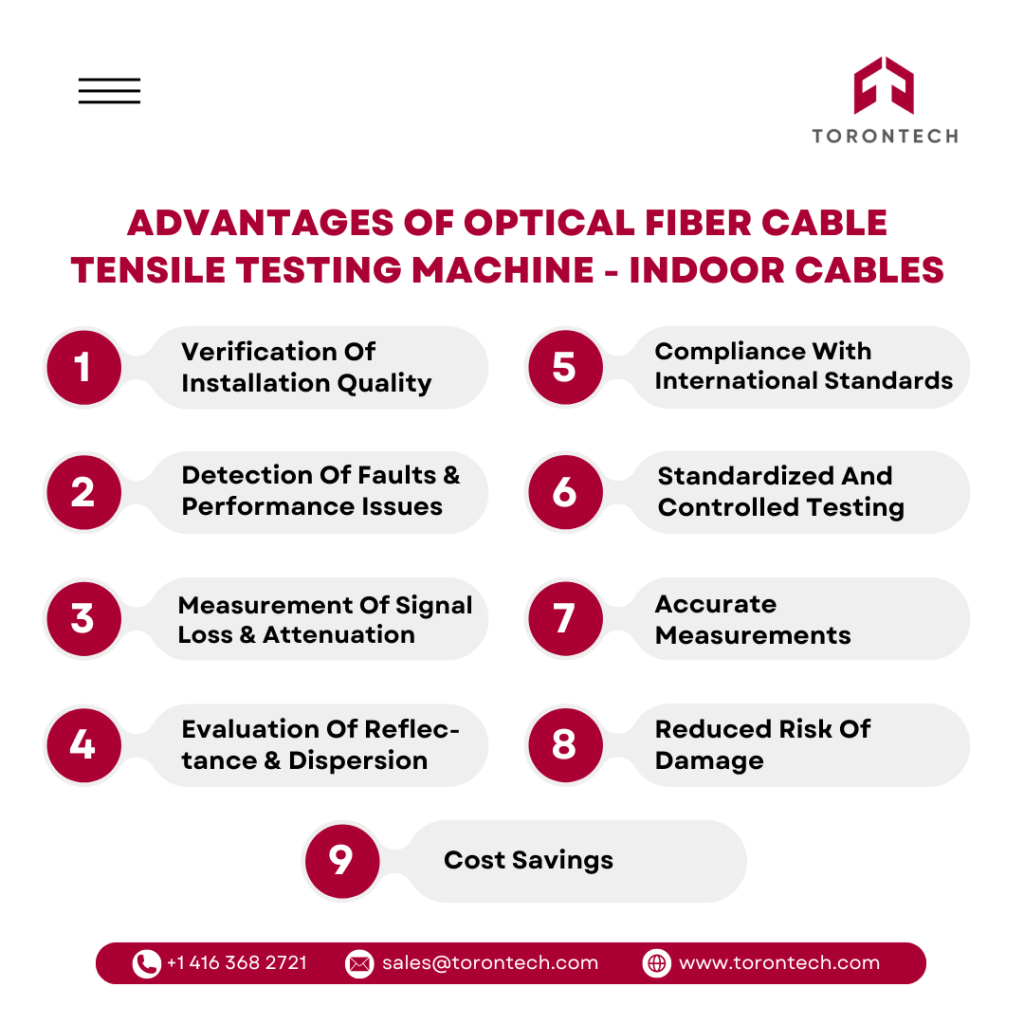

1. Verification Of Installation Quality

Optical cable testing machines designed for indoor cables help verify the quality of cable installations. They apply tensile forces and measure cable elongation to ensure proper termination, splicing, and connection.

2. Detection Of Faults And Performance Issues

These machines detect faults and performance issues by applying tension and observing any changes or anomalies in the cable. This helps identify breaks, bends, or misalignments that may impact signal transmission.

3. Measurement Of Signal Loss And Attenuation

Testing machines measure signal loss and attenuation, enabling technicians to identify excessive loss and optimize cable performance.

4. Evaluation Of Reflectance And Dispersion

Optical cable testing instrument assess reflectance and dispersion levels, minimizing signal degradation and distortions caused by reflection or dispersion.

5. Compliance With International Standards

Using testing machines ensures compliance with industry standards. The International Electrotechnical Commission (IEC) ensures compliance with best practices in the global fiber optic cable industry. They help verify that cables meet required specifications, ensuring compatibility and reliability in communication networks.

6. Standardized And Controlled Testing

Optical fiber cable tensile testing machines are designed to meet international standards, ensuring consistent and reliable results.

7. Accurate Measurements

Optical fiber cable tensile testing machines provide accurate measurements of attenuation and fiber elongation strain, which are essential for characterizing the cable’s performance.

8. Reduced Risk Of Damage

Optical fiber cable tensile testing machines minimize the risk of damage to the fibers during testing, which can be a concern with traditional methods. The risk of cable failure during installation or operation is reduced, improving safety.

9. Cost Savings

Optical fiber cable tensile testing machines can help to identify potential issues before installation, reducing the cost of repairing or replacing damaged cables.

These benefits make Fibre Optic Cable Testing machines important and a valuable equipment for ensuring the quality and reliability of optical fiber cables.

How to Test a Fiber Optic Cable

Testing a fiber optic cable involves a series of steps and the use of appropriate testing equipments. Technicians must follow proper procedures to assess the cable’s performance accurately. The following steps can be followed to test a fiber optic cable based on the provided information.

. Setup and Preparation

- Wind the cable in the testing machine over appropriately sized sheaves.

- Ensure that the cable ends extend to reach the measuring instruments for accurate measurements.

- Concatenate a pre-determined number of fibers within the cable using fusion splicing. Typically, two sets of fibers are used: one for measuring attenuation change and the other for elongation monitoring.

2. Initial Measurements and Calibration

- Perform initial measurements and calibration to establish a baseline for comparison.

- This step ensures accurate and reliable test results.

3. Cable Tensioning

- Pull the cable at a specified rate until a pre-determined tension is applied.

- This tension level is determined based on the cable’s specifications and the desired testing parameters.

4. Tensioned Cable Resting

- Lay the cable to rest under tension according to detailed specifications.

- This allows for evaluating the cable’s behavior and performance under sustained tension.

5. Attenuation and Fiber Length Measurement

- Measure the attenuation, which refers to the loss of signal strength, at the specified tension level.

- This measurement helps identify any excessive signal loss that may affect the cable’s performance.

6. Characterization of Tensile Behavior

- Depending on the testing requirements, the process may involve several tensile levels to characterize the entire tensile behavior of the cable.

- Alternatively, the testing may be carried out only at the defined maximum allowed tension level.

By following these steps, technicians can effectively use Fibre Optic Cable Testing. The process involves winding the cable in the machine, concatenating fibers, performing initial measurements, applying tension, measuring attenuation and fiber length, and characterizing the cable’s tensile behavior. These tests ensure the cable’s performance, durability, and compliance with specified standards.

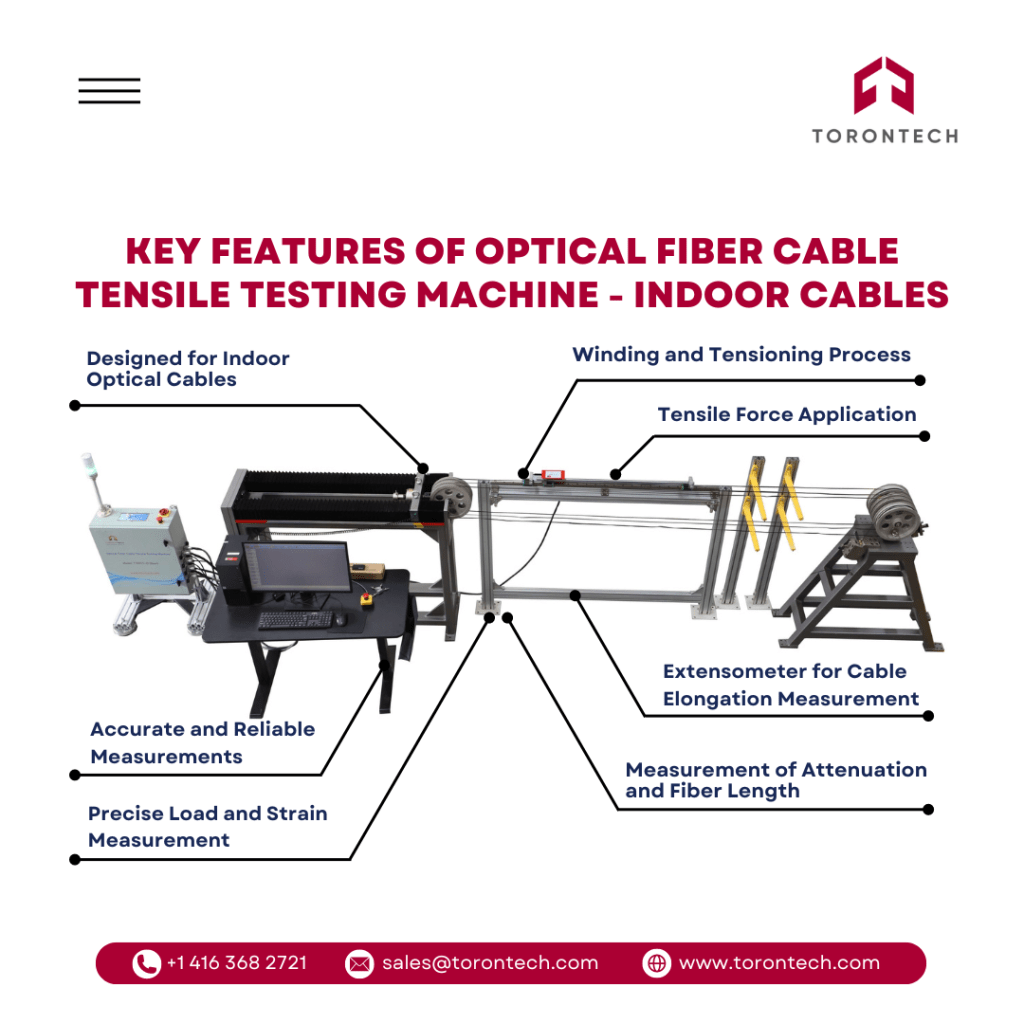

Key Features of Torontech’s Optical Fiber Cable Tensile Testing Machine

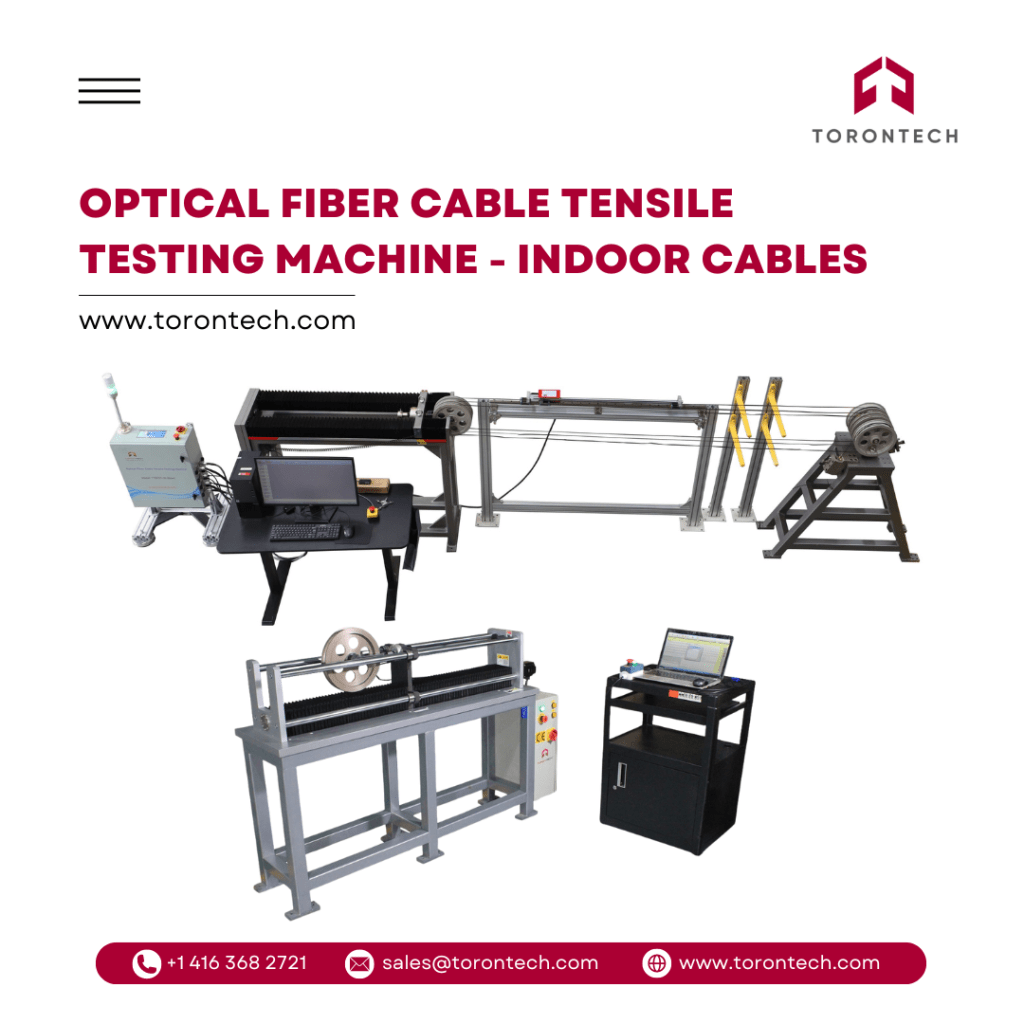

Introducing Torontech’s Optical Fiber Cable Tensile Testing Machine – Indoor Cable (for Bow Type Cables). With its accuracy, reliability, and various specifications, this testing machine ensures thorough evaluations of indoor fiber optic cables. Let’s explore the key features that make this technology a game-changer in the industry.

1. Designed for Indoor Optical Cables

Torontech’s testing machine is specifically designed to cater to the testing needs of indoor optical cables. The machine focuses on indoor applications and ensures accurate and reliable testing results for this specific cable type.

2. Tensile Force Application

The machine applies controlled tensile force to the optical cables being tested. This feature allows technicians to evaluate the cable’s performance and durability under tension, providing valuable insights into its ability to withstand stress and strain.

3. Extensometer for Cable Elongation Measurement

Equipped with an extensometer, the testing machine accurately measures the elongation of the cable under tension. This capability provides precise and quantitative data on how the cable stretches when subjected to load, enabling a thorough assessment of its mechanical properties.

4. Winding and Tensioning Process

The machine facilitates a winding and tensioning process for the sample cable. The cable is wound over an appropriately sized sheave and pulled at a controlled rate until a predetermined tension is achieved. By following detailed specifications, the cable is then laid to rest under tension, replicating real-world installation conditions.

5. Measurement of Attenuation and Fiber Length

Torontech’s testing machine measures two crucial parameters: attenuation and fiber length. Attenuation refers to the loss of signal strength as it travels through the cable. By quantifying the attenuation, technicians can assess the cable’s signal integrity. Additionally, measuring the fiber length helps identify any changes caused by tension and elongation during the testing process.

6. Accurate and Reliable Measurements

The testing machine ensures accurate and reliable measurements. It adheres to an accuracy class of ±0.5% as per ISO 7500-1 standards. With a crosshead travel of 500 mm and a loading speed range of 0.2 to 500 mm/min, it provides precise control over the testing parameters.

7. Precise Load and Strain Measurement

The machine excels in load and strain measurement accuracy. Load measurements are accurate within ±0.5% of the reading to 1/100 of the load weighing system capacity. Strain measurements are similarly precise, with an accuracy of ±0.5% of the reading to 1/50 of the full scale when using compatible extensometers.

Torontech’s Optical Fiber Cable Tensile Testing Machine offers a range of features tailored for indoor optical cables. It applies controlled tensile force, measures cable elongation, and accurately determines attenuation and fiber length. With its precision in load and strain measurements, along with various other specified accuracies, the machine ensures reliable and efficient testing of indoor fiber optic cables.

Conclusion

In the fast-paced world of telecommunications and data centers, the reliability and performance of fiber optic cables are paramount. Fiber optic cable testing equipment, such as the Fibre Optic Cable Tester, play a crucial role in ensuring the integrity of these vital communication channels. By accurately evaluating the tensile strength and performance of fiber optic cables, these testing instruments safeguard the seamless transmission of data and the efficiency of communication networks.

The Fiber Optic Cable Tester offers precise and reliable testing capabilities, allowing technicians and engineers to effectively assess the quality and durability of fiber optic cables.

By measuring the tensile strength, these instruments ensure that the cables can withstand the demanding conditions they encounter during installation and operation. This information is invaluable in identifying potential weaknesses or faults in the cables and preventing issues before they lead to costly downtime or network failures.

By investing in high-quality testing equipment, organizations can proactively maintain the performance and longevity of their telecommunications and data center networks, delivering uninterrupted services to their customers.

Contact us today to learn more about Torontech’s Optical Fiber Cable Tensile Testing Machine. Our team of experts is here to answer your questions, provide detailed information, and discuss how our innovative technology can meet your specific testing needs.