Cables often face bending and twisting during use, which can cause weak points, signal loss, or even failure. These issues can disrupt critical operations in industries like telecommunications and industrial automation. How do manufacturers prevent these problems and ensure reliable performance?

The kink test provides the answer. It simulates extreme bending to identify weak points before cables are used. This process helps manufacturers catch defects, improve durability, and ensure cables deliver consistent performance, giving you confidence in their reliability under real-world conditions.

What is a Kink Test?

The kink test is a key process used to determine how cables perform when subjected to extreme bending forces. It evaluates their ability to maintain integrity without breaking, deforming, or losing functionality.

Think about what happens when you force a cable into a tight loop. It often results in a kink in the cable, a point where the structure weakens and performance degrades. Over time, this can lead to increased attenuation, signal disruptions, or even complete failure of the cable.

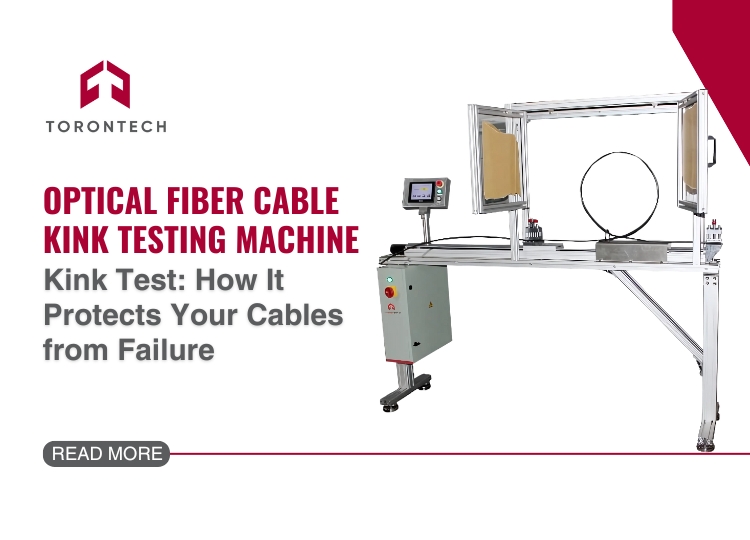

To prevent these issues, the test replicates real-world conditions using advanced machines like the Optical Fiber Cable Kink Testing Machine. These devices apply controlled force to the cable ends, forming a loop while measuring the diameter at which the cable starts to kink.

The goal is straightforward: pinpoint the exact moment where kinks appear and address potential weaknesses before the cable is deployed. This ensures that cables are not only durable but also ready to handle the stresses of real-world applications.

How Kink Tests Prevent Cable Failures

Kink tests are essential for reducing the risks of cable failures, providing insights that improve reliability and performance. Here’s how they make a difference:

1. Detecting Weak Points

The test identifies vulnerabilities caused by subpar materials or flawed construction, giving manufacturers the data needed to enhance durability.

2. Maintaining Signal Integrity

For fiber optics, even a minor kink in fiber optic cable can disrupt signal transmission. Torontech’s Optical Fiber Cable Kink Testing Machine ensures cables perform reliably under stress by preserving signal consistency.

3. Meeting Global Standards

Compliant machines, like Torontech’s kink testing solution, ensure cables align with international standards such as IEC 60794-1-2-E10., boosting trust in their quality.

4. Prolonging Cable Lifespan

Testing eliminates potential points of failure, helping cables last longer and reducing the frequency of replacements. This translates to long-term cost savings and dependable performance.

This process not only prevents immediate issues but also supports long-term reliability in various applications.

How Optical Fiber Cable Kink Testing Machine Works?

The kink testing process follows a structured approach, using advanced equipment like the Optical Fiber Cable Kink Testing Machine to ensure precision and reliability. Here’s how it works:

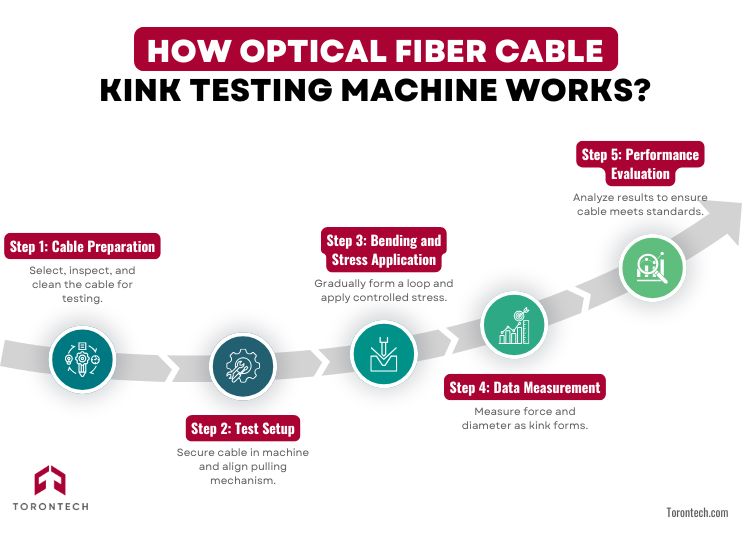

Step 1: Cable Preparation

The sample cable length is selected to meet the requirements of the specified test. The cable is inspected for any pre-existing damage and cleaned thoroughly. This ensures the results focus only on the cable’s performance during the test.

Step 2: Test Setup

The cable is positioned in the testing machine, ensuring it is secured correctly. The pulling mechanism is aligned to apply forces evenly in a single plane. Tools like the kink meter or similar devices are set to measure deformation and force accurately.

Step 3: Bending and Stress Application

The ends of the cable are pulled slowly to form a loop, with the diameter gradually reduced until a kink in the cable begins to appear. The process uses controlled stress to simulate real-world conditions while ensuring no unnecessary damage occurs to the cable.

Step 4: Data Measurement

As the loop diameter decreases, tools like the kink tester or optical cable machine record essential metrics. These include the exact force applied and the diameter at which the kink begins. The machine operates under standard atmospheric conditions unless specified otherwise.

Step 5: Performance Evaluation

After testing, the results are analyzed to determine if the cable meets the required standards. An ideal outcome shows no permanent deformation, signal loss, or other performance issues. Cables that pass this process are ready for use in demanding applications, while failures highlight areas for design improvement.

This precise methodology ensures cables are tested for durability and reliability, preventing unexpected issues during use.

Applications Across Industries

The Optical Fiber Cable Kink Testing Machine is a versatile tool critical to ensuring cable reliability across a wide range of industries. Its ability to simulate real-world bending scenarios makes it indispensable for applications where performance and durability are non-negotiable.

1. Telecommunications

Signal loss is one of the biggest challenges in fiber optic networks. Even a minor kink in fiber optic cable can disrupt communication and impact user experiences. This machine ensures optical cables maintain uninterrupted data flow, supporting high-speed internet, voice calls, and other essential services.

2. Aerospace and Defense

Cables in aerospace and defense systems often face harsh environmental conditions, including extreme temperatures and mechanical stress. Reliable testing ensures these cables endure bending and looping without compromising operational reliability, particularly in mission-critical applications like avionics and radar systems.

3. Data Centers

Data centers house thousands of cables in tightly packed arrangements. The risk of cable kinking is high during installation or maintenance. This machine helps protect cables from bending-related damage, ensuring consistent and uninterrupted data transfer in high-demand environments.

4. Cable Manufacturing

Manufacturers rely on kink testing to guarantee their products meet compliance standards and deliver reliable performance. By identifying vulnerabilities during production, they can improve product quality and reduce customer complaints. This is especially important for manufacturers serving industries like telecommunications, automotive, and industrial automation.

5. Energy and Power Distribution

Cables used in power grids and renewable energy systems, such as wind and solar farms, must withstand significant mechanical stress. Testing for kink in the cable ensures these power lines perform reliably, even in challenging outdoor conditions.

The Importance of Standard-Compliant Kink Testing

Torontech’s machine stands out by fully adhering to IEC 60794-1-2-E10, a critical standard for optical cable performance. This ensures that cables tested on the machine meet global benchmarks for reliability, minimizing risks during installation and use.

Why Choose Torontech?

- Precision Engineering: Designed for accuracy in identifying kink in cable scenarios.

- Efficiency: Streamlines testing processes, saving time and costs.

- Safety: Transparent covers and automated controls enhance user safety during testing.

- Global Compliance: Meets international standards, ensuring product credibility.

Final Thought

The kink test is the foundation of quality assurance for cables, ensuring they stand up to the toughest conditions. With Torontech’s Optical Fiber Cable Kink Testing Machine, you can confidently deliver cables that meet rigorous industry standards.

Looking to enhance your cable testing process? Contact us today and discover solutions designed to deliver consistent, high-quality results.