Accurate chemical analysis often starts with proper sample preparation, but traditional methods can be time-consuming and inconsistent. Microwave digestion offers a solution, combining speed and precision in a way that has transformed laboratory workflows.

From environmental studies to food safety, this innovative technique is helping researchers tackle complex samples with ease. Curious to know how it works and why it’s so effective? Let’s dive in.

What Is Microwave Digestion?

Microwave digestion is a specialized sample preparation method for elemental analysis, breaking down materials into liquid form for precise testing. As noted in Fresenius’ Journal of Analytical Chemistry (1992), its effectiveness lies in understanding microwave-material interactions and optimizing reagents to ensure efficient digestion and accurate analysis across various sample types.

This technique relies on acid digestion, where acids dissolve the sample matrix, leaving trace elements in a clear, particle-free solution. Creating this liquid state is essential for accurate detection of even the smallest concentrations of elements, including toxic metals.

Performed in a microwave digestion system, the process uses controlled heat and pressure in sealed vessels to ensure complete and efficient decomposition, even for tough samples like metals, ceramics, or mining materials.

Industries ranging from food and agriculture to environmental monitoring rely on this method, which has also expanded to emerging fields such as hemp, cannabis, and lithium battery materials. Faster, safer, and more consistent than traditional open-vessel methods, microwave digestion has become a cornerstone of modern laboratory workflows.

It is not surprising that the demand for microwave digestion is high, as it must be a highly reliable method to ensure the integrity of analytical data (Cammann, K., 2010).

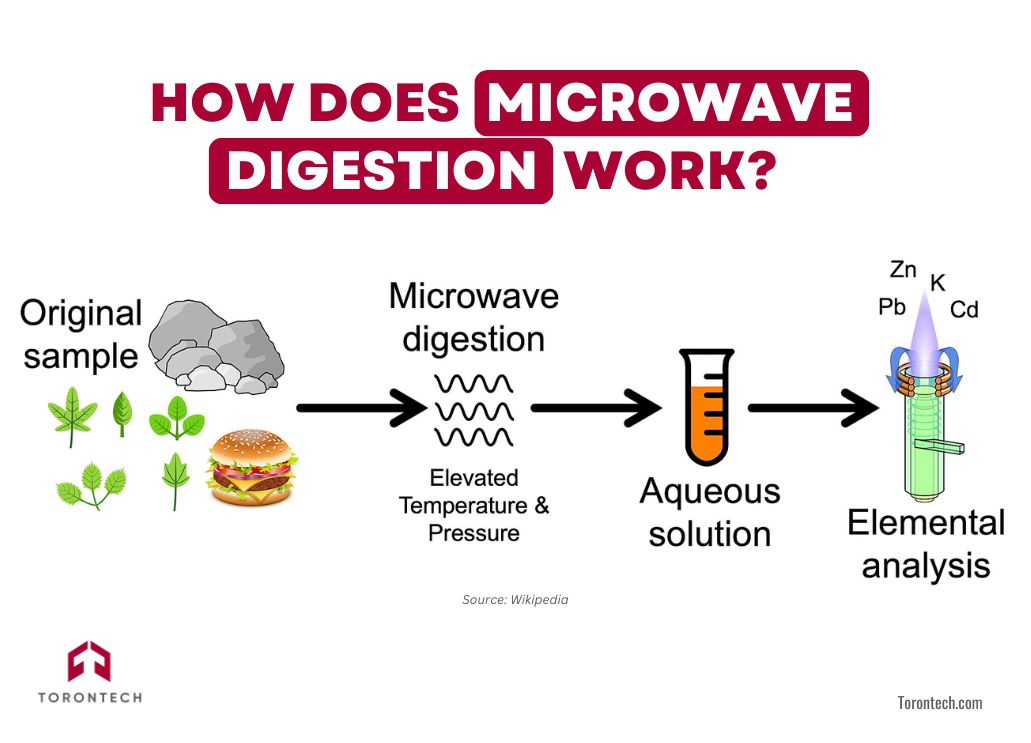

How Does Microwave Digestion Work?

Microwave digestion is a highly efficient sample preparation technique that uses microwave heating in a sealed container to accelerate the acid digestion process. Solid samples are combined with concentrated acids, such as nitric or hydrochloric acid, in reaction vessels.

When heated in this closed environment, temperatures exceeding 200–260 °C -far above the boiling points of the acids- are achieved. This enhances the reaction rate, allowing the sample matrix to break down completely and efficiently.

The process transforms the sample into a clear, particle-free liquid where only trace metals remain in solution. This liquid state is essential for accurate analysis of even small concentrations of toxic metals, as modern analytical equipment requires a contaminant-free medium to deliver precise results.

The controlled temperature and pressure in a microwave digestion system minimize risks of incomplete digestion or contamination, making it ideal for complex matrices such as soil, metals, and ceramics.

Applications of Microwave Digestion in Modern Analysis

1. Microwave Digestion for Sample Preparation

Microwave digestion offers a rapid and efficient way to prepare samples by leveraging direct molecular interaction with microwave energy. Unlike conventional heating, where heat is transferred externally, microwaves penetrate the reaction vessel, heating the sample and acid mixture uniformly and quickly.

Strong acids like nitric or hydrochloric acid are typically used, and sealed vessels ensure no volatile components escape. Modern systems allow temperatures up to 300 °C and pressures up to 200 bar, enabling complete digestion of tough samples like metals, ceramics, and soils.

Safety and precision are key advantages of microwave digestion. Advanced systems feature temperature sensors, pressure relief mechanisms, and instant on/off capabilities to prevent overheating and maintain consistent results.

Additionally, parallel processing allows multiple samples to be prepared simultaneously under identical conditions, saving time and ensuring reproducibility. This combination of efficiency, safety, and adaptability makes microwave digestion an essential technique for modern analytical labs.

2. Microwave Digestion for Metals Analysis

Metals testing demands accuracy, and microwave digestion systems for metals analysis provide the reliability needed for these applications. Laboratories use this technique to prepare samples for methods like ICP-MS (Inductively Coupled Plasma Mass Spectrometry) and AAS (Atomic Absorption Spectroscopy).

Research from the Annals of Work Exposures and Health (2019) highlights the advantages of a newly developed HNO₃-only microwave digestion procedure, demonstrating comparable recoveries with improved reproducibility over traditional methods.

Industries such as mining, environmental monitoring, and electronics rely on microwave digester manufacturers to provide systems capable of handling complex metal matrices. The uniform heating and controlled conditions offered by microwave digestion instruments ensure accurate and reproducible results.

3. Microwave Digestion of Soil Samples

Analyzing soil samples can be challenging due to their complex composition. Microwave digestion simplifies this process, allowing researchers to detect trace elements like lead, arsenic, and cadmium.

Using a microwave digester, soil samples are treated with acids to dissolve both organic and inorganic components. This approach ensures complete breakdown of the matrix, enabling precise measurements

For environmental monitoring, standards like EPA 3051A guide the microwave digestion procedure for soil analysis, ensuring compliance with regulatory requirements.

4. Microwave Digestion in Biological and Food Samples

Biological and food samples require careful handling during preparation to ensure accurate analysis. The microwave digestion method is particularly effective for decomposing these matrices while preserving volatile elements.

For example, microwave digestion instruments are used to analyze plant tissues, animal tissues, and food products for trace elements like mercury and calcium. The ability to adapt digestion programs to specific sample types makes this method versatile and efficient for biological and food testing.

What Are the Advantages and Disadvantages of Microwave Digestion?

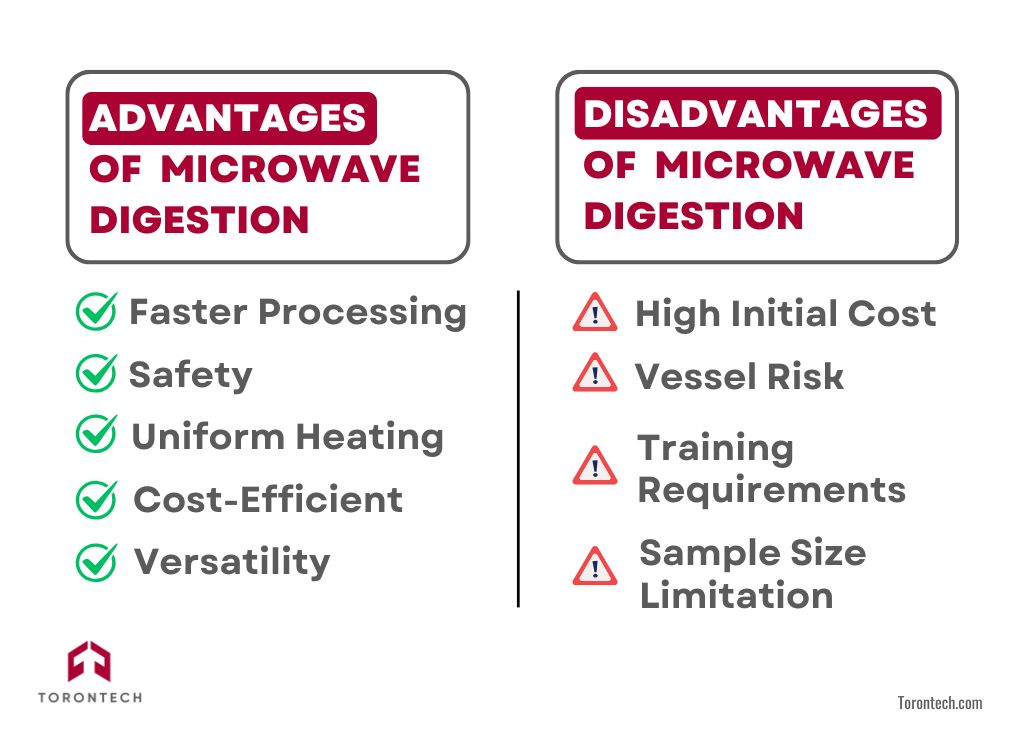

Why do so many labs choose microwave digestion over other methods? Here are some of its key benefits:

A. Advantages

- Faster Processing: Achieves significantly reduced digestion times by reaching high temperatures quickly, compared to traditional open-vessel methods.

- Safety: Sealed vessels prevent exposure to harmful fumes and minimize the risk of spills or contamination.

- Uniform Heating: Ensures consistent and thorough digestion, even for challenging materials like metals, ceramics, and soils.

- Cost-Efficient: Requires less reagent, reducing both expenses and chemical waste.

- Versatility: Adapts to a wide range of sample types, including metals, biological tissues, and environmental samples.

B. Disadvantages

However, it’s important to consider some limitations:

- High Initial Cost: Microwave digestion systems and accessories can be expensive to acquire.

- Vessel Risk: Sealed reaction vessels may crack or explode under high pressure if not properly handled, especially with aggressive reagents.

- Training Requirements: Operators need specialized knowledge to use and maintain the system effectively.

- Sample Size Limitation: Restricted by the capacity of digestion vessels, potentially limiting throughput.

Despite these limitations, the benefits of microwave digestion make it a preferred method for many analytical laboratories.

Practical Tips for Effective Microwave Digestion

Want to get the best results from your microwave digestion system? Keep these tips in mind:

- Choose the appropriate acid reagents for your sample type. For instance, nitric acid is ideal for metals, while sulfuric acid may be better for organic materials.

- Avoid overloading digestion vessels to ensure consistent results.

- Regularly inspect vessels for signs of wear or damage.

- Document digestion parameters that work well for specific sample types to maintain consistency.

- Troubleshoot issues like incomplete digestion promptly, adjusting the program or reagents as needed.

Following these best practices will help you maximize the potential of your microwave digestion equipment and avoid common pitfalls.

Final Thoughts

Microwave digestion has transformed sample preparation, offering faster, safer, and more reliable methods for laboratories worldwide. Whether you’re testing metals, soils, or biological tissues, its ability to handle complex matrices with ease makes it invaluable.

From the microwave digestion principle to its applications across industries, this method simplifies processes while delivering consistent results.

Have more questions about microwave digestion systems or the best options for your lab? Explore our extensive range of microwave digester or connect with our experts to learn more. With the right tools and knowledge, you can take your sample preparation to the next level.

References:

- Cammann, K. (2010). Instrumentelle Analytische Chemie. Spektrum Akademischer Verlag, Heidelberg.

- Kuss, H.M. Applications of microwave digestion technique for elemental analyses. Fresenius J Anal Chem 343, 788–793 (1992).

- Schwank, T., Pitzke, K., Gusbeth, K., Ashley, K., & Breuer, D. (2019). Comparison of Microwave-Assisted digestion and consensus Open-Vessel digestion procedures for evaluation of metalliferous airborne particulate matter. Annals of Work Exposures and Health, 63(8), 950–964.