The Ultra Centrifugal Mill is a versatile tool for sample preparation, featuring rapid performance due to its high rotor speed capability. With the potential to attain a final fineness of less than 40μm, this mill facilitates swift processing of a wide range of sample types, including soft, hard, brittle, and fibrous materials.

Its adjustable speeds, spanning from 6000 to 18000rpm, further enhance its adaptability to diverse milling requirements. For a deeper understanding of the Ultra Centrifugal Mill and its various applications, delve into our comprehensive blog post.

What is an Ultra Centrifugal Mill?

The Ultra Centrifugal Mill is a powerful and versatile rotor mill instrument designed to cater to a broad spectrum of sample types that utilizes centrifugal force to grind materials. With its highly efficient grinding technology, this mill excels in both dry and wet grinding applications. It is commonly used in laboratories and research facilities to efficiently grind soft to medium-hard and fibrous materials.

The mill operates by feeding the material into the center of the rotor, which is equipped with a series of blades. The high-speed rotation of the rotor creates centrifugal force, which pushes the material outward towards the grinding walls. As the material collides with the grinding walls, it is pulverized into fine particles. Its unique two-step grinding process, involving a rotating mill knife and a ring screen system, enables rapid and precise sample processing across various materials.

One of the key strengths of the Ultra Centrifugal Mill lies in its ability to deliver exceptional performance for different sample types. By leveraging its advanced grinding technology, this mill achieves rapid results while maintaining sample integrity. Whether you’re working with delicate biological samples, tough geological materials, food processing, or challenging polymers, the Ultra Centrifugal Mill provides a reliable solution for efficient sample preparation.

The mill’s versatility extends beyond its grinding capabilities. With a comprehensive set of accessories, the Ultra Centrifugal Mill can adapt to specific experimental requirements. From different-sized chambers and screens to specialized rotor configurations, these accessories allow for further customization and optimization of the grinding process.

This flexibility empowers researchers, scientists, and professionals to tailor their sample preparation techniques and achieve the desired outcomes in their respective fields.

Function Principle of Ultra Centrifugal Mill

The working principle of the Ultra Centrifugal Mill is tailored to ensure efficient and precise grinding of samples. This instrument achieves a two-stage crushing process using the rotor and ring sieves to ensure particularly gentle but fast processing.

Here is a breakdown of its working principles, specifically focusing on the sample preparation, impact force, and crushing process.

1. Sample Introduction

The Ultra Centrifugal Mill features a hopper designed to prevent splashing during sample introduction. This ensures a controlled and mess-free loading of the samples into the grinding chamber.

2. Impact Force

Once the samples are introduced, the high-speed rotation of the rotor and the centrifugal force generated in the mill creates a powerful impact force. This impact force serves as a pretreatment for the samples, preparing them for further grinding.

3. Shearing, Extrusion, and Rubbing

As the samples undergo the impact force, they experience shearing, extrusion, and rubbing between the rotor and the ring sieves. These mechanical actions contribute to the effective reduction of particle size and the breakdown of the sample structure.

4. Crushing Process

The Ultra Centrifugal Mill employs a two-stage crushing approach. Initially, the impact force serves as the first stage of crushing that involves mills knife, achieving a moderate reduction in sample size. Subsequently, as the sample particles become smaller than the aperture of the ring sieves, they move to the second stage of crushing.

5. Collection of Finer Particles

In the second stage, when the sample size becomes smaller than the aperture of the ring sieves, the finer particles pass through the sieves and are collected in a pan. This ensures the separation and collection of the desired particle size range for further analysis or processing.

The high crushing efficiency of the Ultra Centrifugal Mill allows for a relatively short grinding time for the samples. This minimizes the exposure of the samples to the grinding chamber, reducing the likelihood of alterations in sample properties and ensuring accurate and consistent results.

The combination of impact force, shearing, extrusion, rubbing, and the 2 stage crushing process ensures optimal sample preparation, making the mill a valuable tool in various research, analytical, and industrial applications.

Typical Samples Materials

The Ultra Centrifugal Mill is highly versatile and capable of efficiently grinding various sample materials. It enables rapid processing of samples, whether they are soft, hard, brittle, or fibrous. You can find examples of materials that can be processed with this instrument in the table below.

| Type | Materials |

| Soft | Collagen, Dried fruit and vegetables, Drugs, Feed pellets, Food, Paper, Pharmaceuticals sample, Polymers, Rubber, Textiles, Tobacco, Wood |

| Medium-Hard | Minerals, Ores, Ceramics, and Certain types of wood |

| Hard | Electronic components, Graphite, Minerals |

| Brittle | Bones, Coal, Graphite, Minerals, Seeds, Spices, Straw |

| Fibrous | Bones, Cereals, Corn, Dried fruit and vegetables, Dried larvae, Paper, Plant materials, Seeds, Straw, Textiles, Tobacco, Wood |

| Water-Containing | Cereals, Collagen, Corn, Dried fruit and vegetables, Dried larvae, Drugs, Feed pellets, Food, Pharmaceuticals sample, Plant materials, Polymers, Seeds, Straw, Sweets, Tobacco, Waste, Wood |

| Dry | Bones, Chemical products, Coal, Electronic components, Graphite, Minerals, Paper, Pharmaceutical materials, Powder coatings, Seeds, Spices, Sweets, Tobacco, Waste, Wood |

The versatility of the Ultra Centrifugal Mill makes it suitable for a wide range of applications broad spectrum of samples. It is particularly beneficial when samples require fast and efficient grinding to achieve the desired particle size distribution.

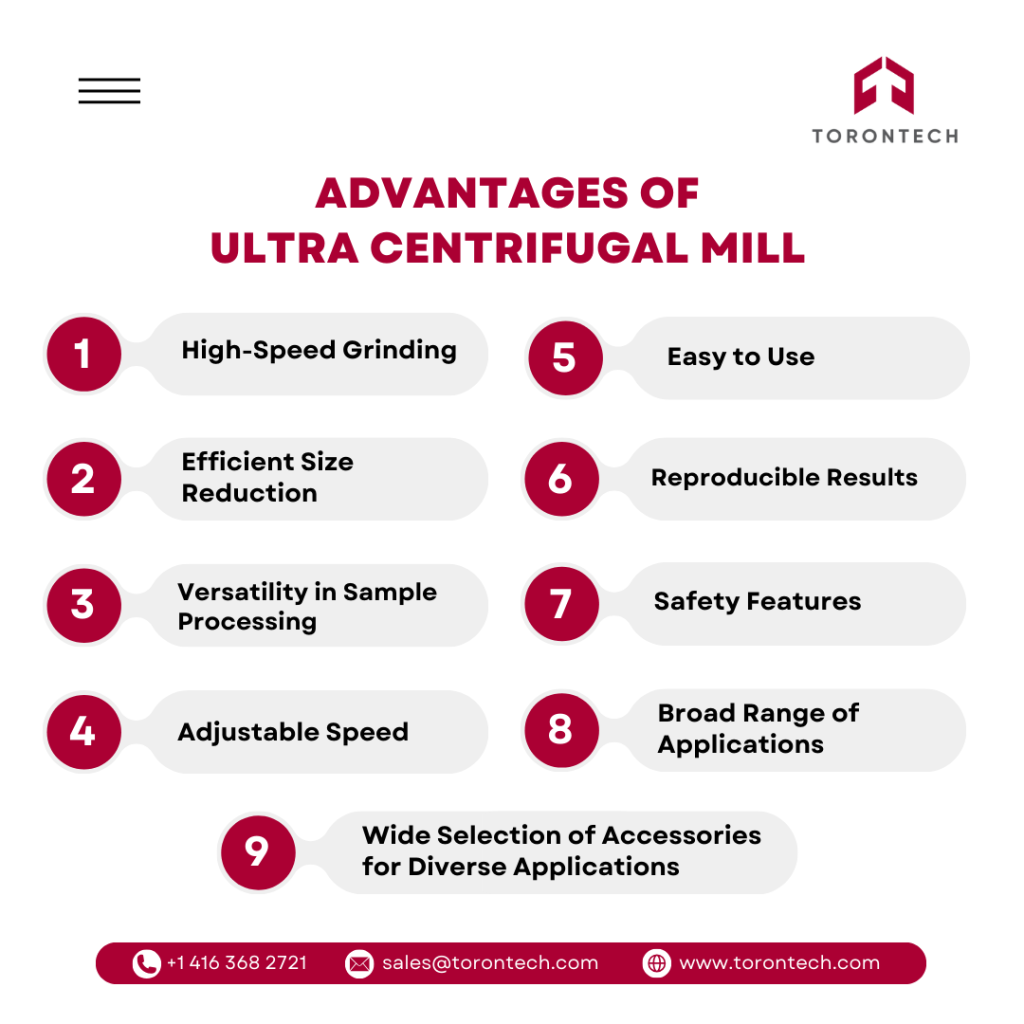

What Are the Advantages of Ultra Centrifugal Mill?

The Ultra Centrifugal Mill offers a multitude of advantages that make it a highly valuable instrument for sample preparation in various industries and research fields. Let’s explore the key advantages of this innovative mill and how they contribute to efficient and precise sample processing.

1. High-Speed Grinding

The mill operates at high rotational speeds, typically ranging from 6000 to 18000 rpm. This allows for rapid grinding and reduces the processing time required to achieve the desired fineness of the sample.

2. Efficient Size Reduction

The combination of high-speed rotation and centrifugal force enables efficient size reduction of a wide range of materials with the final fineness of 40 μm (d90). It can quickly grind materials to fine particle sizes.

3. Versatility in Sample Processing

The mill is capable of grinding various types of materials, including soft, medium-hard, and fibrous substances. It can handle a diverse range of samples, making it suitable for use in different industries and research fields.

4. Adjustable Speed

The Ultra Centrifugal Mill offers adjustable speed settings, allowing users to optimize the grinding process for different materials. This flexibility enables customization based on the specific requirements of the samples being processed.

5. Easy to Use

The mill is designed for ease of use, with straightforward operation and minimal maintenance requirements. It typically features user-friendly controls and can be quickly set up for grinding experiments.

6. Reproducible Results

The Ultra Centrifugal Mill provides consistent and reproducible grinding results, ensuring reliable data for research and analysis purposes. This is important for obtaining accurate and comparable results across different experiments.

7. Safety Features

Many Ultra Centrifugal Mills are equipped with safety features such as automatic shutdown mechanisms, interlocking systems, and protective enclosures to ensure the user’s safety during operation.

8. Broad Range of Applications

It finds utility in areas such as sample preparation for analytical techniques (e.g., spectroscopy, chromatography), material characterization, quality control, formulation development, and research across diverse scientific disciplines.

9. Wide Selection of Accessories for Diverse Applications

The Ultra Centrifugal Mill offers a variety of accessories to accommodate different applications. With options such as various ring sieves and specialized rotors, users can customize the mill to achieve precise particle size control. This versatility allows for optimal adaptation to a wide range of sample materials and applications.

These advantages make the Ultra Centrifugal Mill a valuable tool in laboratories, research facilities, and industries where efficient and high-quality grinding of various materials is required.

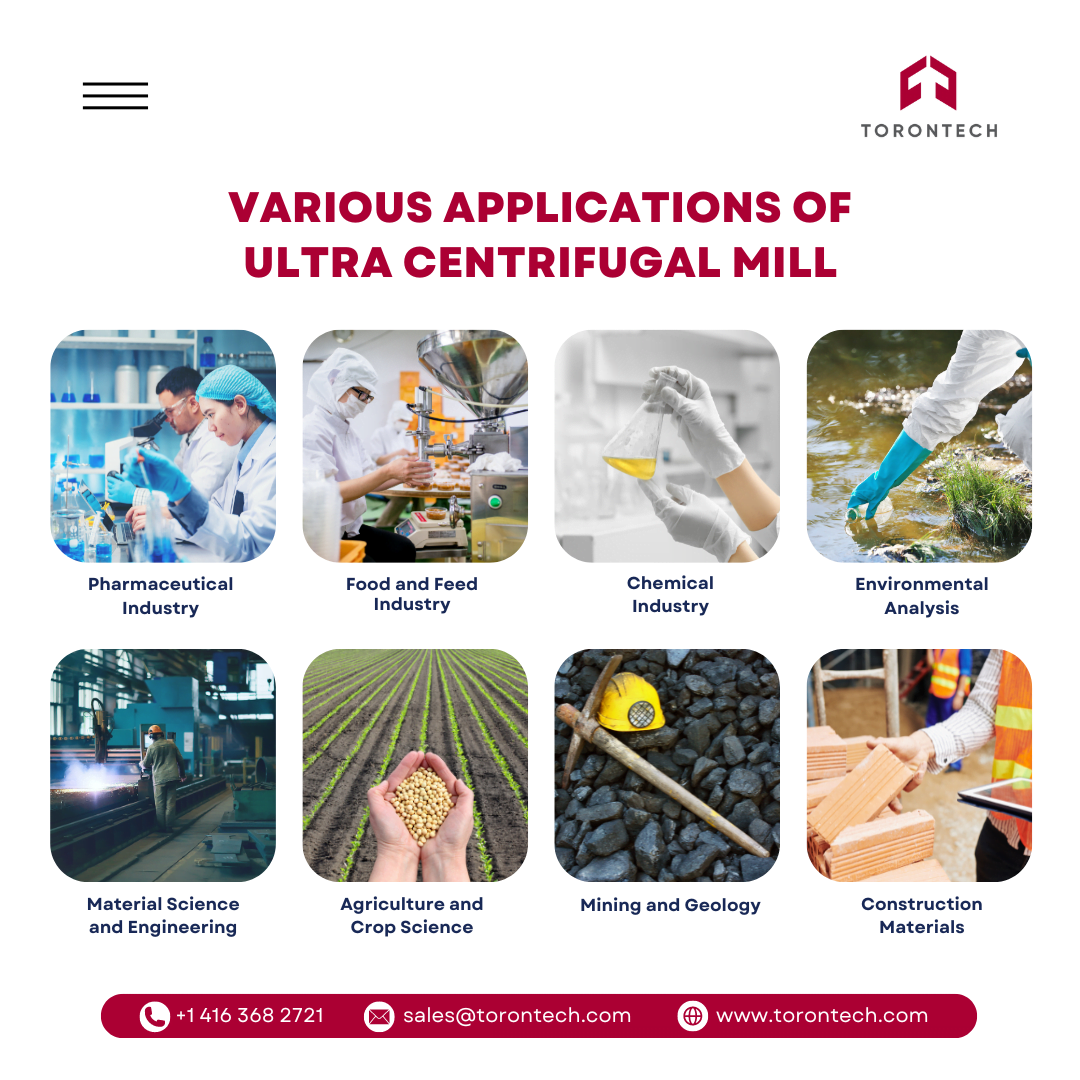

Various Applications of Ultra Centrifugal Mill

The Ultra Centrifugal Mill is a versatile tool that finds application in numerous industries and research fields. Its efficient grinding capabilities, versatility in sample processing, and precise control over particle size make it valuable for a wide range of applications. Here are some industries where the Ultra Centrifugal Mill is commonly used.

1. Pharmaceutical Industry

In the pharmaceutical industry, the Ultra Centrifugal Mill is instrumental in drug development and formulation. It effectively grinds active pharmaceutical ingredients (APIs), excipients, and formulations, enabling homogenization, particle size reduction, and blending. This assists in optimizing drug formulations, ensuring consistent drug delivery, and evaluating product stability.

2. Food and Feed Industry

The Ultra Centrifugal Mill is employed in the food industry for grinding food samples and ingredients. It is used to grind grains, spices, seeds, coffee beans, and other food materials. It contributes to processes such as food formulation, flavor development, quality control, and facilitating sample homogenization and particle size reduction.

3. Chemical Industry

The mill finds applications in the chemical industry for grinding various chemical substances. It is used for particle size reduction, formulation development, and sample preparation for chemical analysis. It is valuable in areas such as catalyst production, polymer processing, and pigment manufacturing.

4. Environmental Analysis

The Ultra Centrifugal Mill is utilized in environmental analysis and research. It is used to grind environmental samples such as soil, sediments, rocks, and minerals. It aids in sample preparation for elemental analysis, contaminant determination, and soil characterization.

5. Material Science and Engineering

Materials scientists rely on the Ultra Centrifugal Mill for sample preparation and characterization. It can process a wide range of materials, including metals, alloys, ceramics, and composites. The mill assists in achieving desired particle sizes and homogeneity, essential for evaluating material properties, studying phase transitions, and analyzing material structures.

6. Agriculture and Crop Science

The Ultra Centrifugal Mill is employed in agricultural research and production. It is used to grind plant materials, seeds, or agricultural products for analysis, breeding, formulation, and quality control purposes. It aids in crop science research, seed testing, and agricultural product development.

7. Mining and Geology

The Mill finds application in the mining and geology industries. It is used for grinding rocks, ores, minerals, and geological samples. It aids in sample preparation for mineral analysis, elemental determination, and geological research.

8. Construction Materials

This instrument plays a significant role in the preparation and characterization of construction materials. It is employed in the grinding and analysis of various materials used in construction, such as cement, concrete, aggregates, and minerals. The mill assists in achieving uniform particle sizes and homogeneity, enabling accurate assessment of material properties, performance, and quality control.

Its versatility, efficient grinding capabilities, and precise control over particle size make it a valuable asset in research laboratories, industrial settings, and academic institutions across multiple fields. The mill’s ability to process various sample materials and contribute to accurate and reliable data generation makes it an essential tool for advancing scientific knowledge, product development, and quality control in numerous industries.

Conclusion

The Ultra Centrifugal Mill is a highly efficient tool for sample preparation, offering precise control over grinding parameters and finding applications across various industries. With its robust design and rapid grinding capabilities, it provides effective sample homogenization for a wide range of materials. Researchers, quality control departments, and industrial professionals benefit from its versatility in achieving desired particle sizes and preparing samples for analysis.

To learn more about the technical specifications and customization options of the Ultra Centrifugal Mill for your specific needs, please visit here or contact us today. Our team of experts is ready to provide detailed information and assist you in optimizing your sample