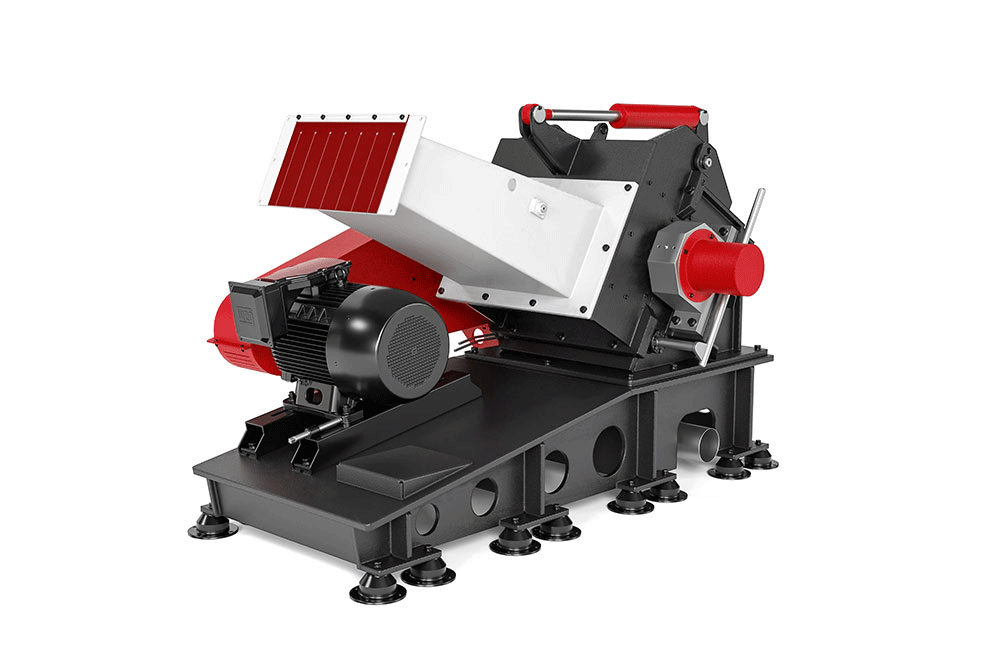

Crusher for Plastic Recycling

Plastic crusher is designed and used for crushing various kinds of plastic materials into granules of different size. Crushed plastics can be recycled for reproduction of plastic products. This machine can help reduce the volume of plastic waste, greatly save costs and resources. Torontech offers a diverse range of Plastic Recycling Crusher models to cover a multitude of different capacities and applications.

Wide Application of Plastic Crusher

How does Plastic Crusher Work?

The motor of the plastic crusher drives moving blade cutter to rotate at high speed. High speed rotating moving blades form a relative movement with fixed blades. Through the clearance between them, big materials will be crushed into small sizes. Crushed plastics that meet requirements will be discharged through the screen mesh. The size of this screen determines the final particle output size.

Features of Plastic Crusher

Product Categories

Crusher - Plastic Crusher Machine For Grinding Long Plastic Pipes

The Crusher - Plastic Crusher Machine For Grinding Long Plastic Pipes are engineered to grind lengthy plastic pipes and profiles...

Crusher - Heavy Duty Plastic Crushers Grinding Machine

The Crushers - Heavy Duty Plastic Crushers Grinding Machine are built to handle tough materials and meet demanding grinding needs with a robust welded steel structure...

Crusher - High Output Efficient Plastic Crusher Machine

The Crusher - High Output Efficient Plastic Crusher Machine is a specialized crusher designed for high output and low energy...