When you think about industrial machines, few are as versatile and effective as a ball mill. Whether you’re in mining, manufacturing, or laboratory research, ball mills provide the perfect solution for transforming raw materials into precisely ground powders or particles.

These machines have become an important tool across various industries, offering efficiency and adaptability for numerous applications.

If you’re curious about how they work, their advantages, and what makes them unique compared to other grinding mills, this guide will help you explore the ins and outs of ball mills. Let’s start with the basics.

What Is a Ball Mill?

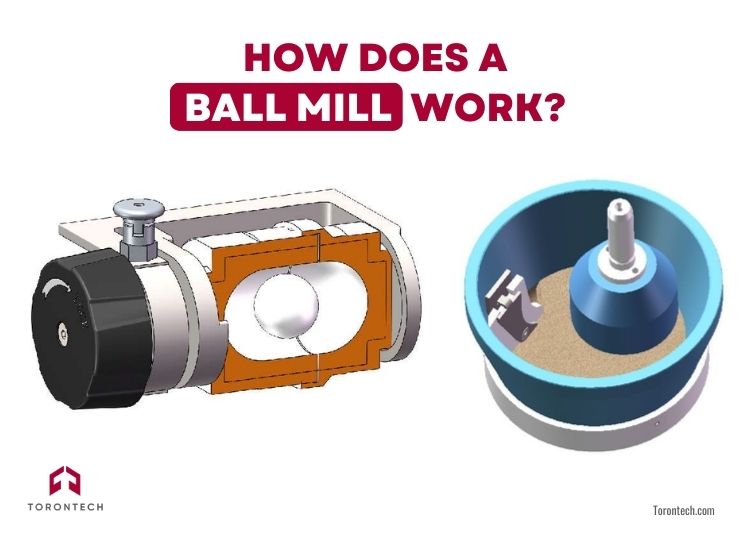

A ball mill is a grinding machine designed to reduce materials into an extremely fine powder. It consists of a hollow cylindrical shell that rotates around a horizontal axis. Inside the cylinder, you’ll find grinding media—typically stainless steel, ceramic, or rubber balls—mixed with the material to be ground. As the cylinder rotates, the balls tumble, collide, and create both impact and friction, breaking down the material into finer particles.

Engineered to deliver superior performance, ball mills work on the principles of impact (as the balls drop onto the material) and attrition (as they rub against the material and each other). This dual-action grinding ensures consistent results, whether you’re handling brittle, hard, or fibrous substances.

What Is a Ball Mill Used For?

Ball mills are incredibly versatile, making them suitable for a range of industries. If you ask “What can be done w a ball mill?”, these are the answers!

- Material Grinding: Pulverize ores, minerals, and raw materials for mining or manufacturing.

- Mixing: Blend materials for paints, ceramics, or pharmaceuticals.

- Fine Particle Creation: Produce powders for pyrotechnics or advanced research.

- Research Applications: Grind small samples for material testing and analysis.

Whether for wet or dry grinding, ball milling delivers precision and adaptability for nearly any material processing task.

How Does a Ball Mill Work?

The operation of a ball mill might seem straightforward, but it’s a finely tuned process that combines mechanics and material science. At its core, the ball mill functions on two main principles: impact and attrition. Together, these forces ensure that materials are broken down effectively into the desired size.

1. Impact

Impact is the primary mechanism that reduces the size of materials in a ball mill. As the cylindrical shell rotates, the grinding media (balls) are carried upward by the motion. When they reach a certain height, gravity pulls them down with force, causing them to collide with the material inside the mill.

This high-energy impact is particularly effective at breaking larger particles into smaller fragments. Think of it as a hammer repeatedly striking the material, creating a consistent reduction in particle size. The efficiency of this process depends on factors such as the rotational speed of the mill and the density of the grinding media.

2. Attrition

While impact fractures large particles, attrition focuses on refining them further. As the balls tumble and move within the rotating shell, they rub against each other and the material being ground. This constant friction generates a grinding effect that smoothens the edges of particles and reduces their size even more.

Attrition is especially effective for creating finer particles and achieving uniformity in size. The intensity of attrition can be influenced by the mill’s speed, the surface texture of the balls, and the nature of the material being processed.

This dual action ensures that materials are ground evenly and thoroughly. The speed, size of the balls, and material properties all play a role in achieving the desired results.

What Makes a Ball Mill Different?

Ball mills are part of a broader category of grinding mills, but they stand out in several ways:

1. Ball Mill vs. Tumbling Mill: What’s the Difference?

While ball mills and tumbling mills are often grouped together, they aren’t identical:

- Ball Mills: Use metallic or ceramic balls to crush materials, focusing on fine particle sizes.

- Tumbling Mills: Include variations like tube mills, which may use mixed media and often involve wet grinding, creating a slurry.

Think of a ball mill as a specialized version of a tumbling mill, engineered for precision and consistency.

2. Ball Mill vs. Grinding Mill: Are They the Same?

Not exactly. While a ball mill is a type of grinding mill, not all grinding mills are ball mills. Grinding mills encompass a range of machines designed for pulverizing materials, including attritor mills and rod mills.

The key difference lies in the grinding media:

- Ball Mills: Use spherical grinding media, like balls, to crush and grind materials.

- Other Grinding Mills: May use rods, beads, or other shapes tailored to specific tasks.

Understanding these nuances can help you choose the right mill for your application.

Types of Ball Mills

Different ball mill designs cater to various grinding needs, each with unique operational principles:

Advantages and Disadvantages of Ball Mills

Ball mills are widely used in various industries for their efficiency and versatility, but like any equipment, they come with their own set of advantages and limitations. Here’s a closer look at the pros and cons of using ball mills:

A. Advantages of Ball Mills

1. Fine and Consistent Grinding

Ball mills are capable of producing extremely fine powders with particle sizes as small as 10 microns, making them ideal for applications requiring high precision.

2. Versatile Across Industries

From mining to pharmaceuticals, ball mills can grind a wide variety of materials, including ores, ceramics, chemicals, and pigments.

3. Adaptable for Wet and Dry Grinding

Ball mills can operate in both wet and dry modes, offering flexibility for different materials and applications.

4. Continuous Operation

Designed for ongoing use, ball mills are efficient for large-scale production processes without frequent interruptions.

5. Durable and Reliable

With proper maintenance, ball mills can handle abrasive materials and deliver consistent performance over long periods.

6. Safe for Hazardous Materials

Enclosed grinding minimizes exposure to toxic or reactive materials, making them suitable for sensitive applications.

B. Disadvantages of Ball Mills

1. Energy-Intensive Operation

Ball mills consume significant power, which can lead to higher operational costs and increased carbon emissions.

2. Wear and Tear

The grinding media and liners are subject to constant abrasion, requiring regular replacement and maintenance.

3. Noise Levels

Without proper soundproofing, ball mills can generate considerable noise, which may be disruptive in certain environments.

4. Size Limitations

While ball mills excel at fine grinding, they may not be ideal for extremely large-scale operations where other grinding methods could be more efficient.

5. Inconsistent Particle Distribution

Achieving uniform particle size may require adjustments and careful monitoring, especially for complex materials.

Ball mills remain an important tool for many industries due to their precision and adaptability, but their high energy requirements and maintenance needs should be carefully considered when selecting a grinding solution. Understanding these pros and cons ensures better decision-making for your material processing requirements.

Applications of Ball Mills Across Industries

Ball mills are integral to numerous industries, thanks to their ability to grind and blend materials into precise sizes and textures. Their versatility makes them indispensable in both large-scale production and specialized research. Below are key industries and applications where ball mills play a critical role:

1. Chemical and Pharmaceutical Industries

Ball mills are widely used for mixing and grinding chemicals, creating uniform powders for chemical reactions or pharmaceutical formulations. Their enclosed design ensures safe handling of toxic or reactive substances, making them ideal for sensitive applications.

2. Ceramics and Advanced Materials

The ceramics industry relies on ball mills to grind materials like feldspar and clay into fine powders. These are then used in making tiles, pottery, and advanced ceramics. The precise grinding capabilities of ball mills ensure the production of high-quality ceramic products.

3. Food and Agriculture

In the food industry, ball mills are used to process ingredients like cocoa, spices, and grains. Their ability to produce fine, consistent powders is essential for creating high-quality food products and agricultural additives.

4. Mining and Metallurgy

Ball mills are extensively used to grind ores into fine powders, a critical step in extracting valuable minerals like gold, silver, and copper. They help in refining raw materials to prepare them for further processing, ensuring efficiency and effectiveness in mineral recovery.

5. Research and Development

Laboratories and research institutions use ball mills to prepare small samples for analysis or to develop new materials. Their ability to grind and blend with precision makes them invaluable for testing and experimental purposes.

6. Specialized Applications

Ball mills also find niche uses in fields like:

- Pyrotechnics: Producing fine powders for fireworks and black powder.

- Recycling: Grinding materials for reuse, such as glass or electronic waste.

- Food Processing: Milling grains and spices into fine powders for culinary and industrial purposes.

Closing Thoughts

The ball mill is more than just a machine. It’s a versatile tool that powers industries and research alike. Its ability to grind and blend materials efficiently makes it indispensable in processes requiring fine powders or precise particle sizes. Whether you’re in mining, manufacturing, or a lab, understanding how a ball mill works and its advantages can help you maximize its potential for your projects.

If you’re looking for reliable, high-performance ball mills, Torontech offers an extensive range tailored to meet the demands of industries worldwide. Explore our comprehensive collection of ball mills designed for precision, durability, and efficiency. Visit Torontech Ball Mills to find the perfect solution for your application.

Frequently Asked Question (FAQ)

2. We handle diverse materials. How do we select the right type of ball mill for our specific needs?

The versatility of ball mills is a key advantage, with different types designed for specific applications. For example, a planetary ball mill offers ultra-fine grinding for advanced materials, while a hammer mill is better suited for brittle substances. For temperature-sensitive samples, a cryo-grinder is ideal. To navigate these options, consulting with an experienced supplier like Torontech can help you match the right mill—and the right grinding media—to your specific material properties and throughput requirements.

3. What is the business impact of a ball mill's energy consumption, and how can we manage it?

While ball mills are powerful, their energy consumption is a significant operational cost. However, this cost must be weighed against the value of achieving fine, consistent grinding that other methods cannot. To manage this, it's crucial to optimize the grinding process by selecting the correct mill size, ball media, and rotational speed for your application. Partnering with a provider like Torontech can ensure you select an efficiently engineered model designed to maximize grinding performance while managing energy usage.

4. How can a ball mill support our R&D and new material development processes?

In research and development, ball mills are invaluable for creating and testing new formulations. They allow for the precise grinding and blending of small sample batches, which is essential for material science, chemical, and pharmaceutical research. Specialized lab-scale models, such as high-energy or planetary ball mills, offer the high degree of control needed to develop innovative materials and test their properties before scaling up to full production.

5. For achieving a fine powder, why choose a ball mill over other types of grinding mills?

A ball mill is superior for producing extremely fine and consistent powders due to its dual-action grinding mechanism of impact and attrition. While other grinding mills exist, ball mills are specifically engineered to excel at this fine pulverization. The enclosed system is also safer for handling hazardous or sensitive materials, which is a critical advantage in the chemical and pharmaceutical industries, making it the preferred choice where purity and safety are paramount.

- Kumar, D. S., Kumar, B. J., & Mahesh, H. (2018). Quantum Nanostructures (QDs): An Overview. In Elsevier eBooks (pp. 59–88).

-

Liang, L., Wang, F., Rong, M., Wang, Z., Yang, S., Wang, J., & Zhou, H. (2020). Recent advances on preparation method of TI-Based hydrogen storage alloy. Journal of Materials Science and Chemical Engineering, 08(12), 18–38.