Ball milling is one of the most effective tools you can use to simplify laboratory sample preparation. If you’ve ever struggled with inconsistent particle sizes or wasted time reprocessing materials, you know how frustrating it can be to rely on unreliable methods.

Fortunately, the ball mill machine offers a solution that combines speed, precision, and adaptability. It allows you to process a wide range of materials with ease, delivering uniform, high-quality samples ready for analysis. Saving you both time and effort.

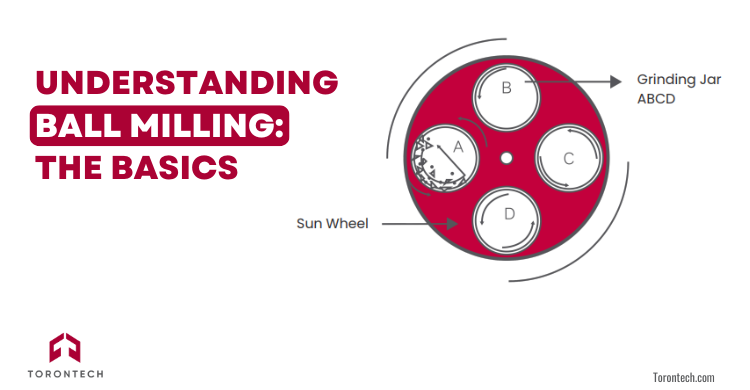

Understanding Ball Milling: The Basics

Ball milling is a versatile grinding process that transforms materials into extremely fine powders. At its core, the method involves a rotating cylindrical chamber partially filled with grinding media such as ceramic, flint pebbles, or stainless steel balls.

As the chamber rotates, these rigid balls collide with the material, creating localized high pressure that breaks it down into smaller, more uniform particles.

What makes ball milling unique is its adaptability. Whether you’re working with brittle minerals, soft polymers, or even nanotubes, this technique accommodates both dry and wet grinding processes. Its precision and efficiency make it indispensable for diverse laboratory applications, from material research to sample preparation.

If you’re curious about how they work, their types, and applications, feel free to explore more in this article.

How Ball Milling Enhances Laboratory Operations

1. Sample Homogenization

Laboratories often work with heterogeneous materials that require uniform particle distribution. Ball mills excel at breaking down bulk materials into evenly distributed fine powders, ensuring consistency across samples. This homogenization is crucial for accurate analysis and reproducibility in experiments.

2. Preparing Advanced Nanomaterials

In cutting-edge research, the demand for nanomaterials is ever-increasing. Ball milling is a go-to method for producing cellulose nanocrystals (CNCs) and cellulose nanofibers (CNFs), widely used in biocomposites, coatings, and medical applications.

The fine control offered by ball mills allows laboratories to manipulate particle sizes and morphologies, achieving desired properties in the final material.

3. Mixing and Blending

Beyond grinding, ball mills can mix and blend materials, making them ideal for developing composite materials or preparing chemical mixtures. This dual functionality saves time and reduces the need for additional equipment.

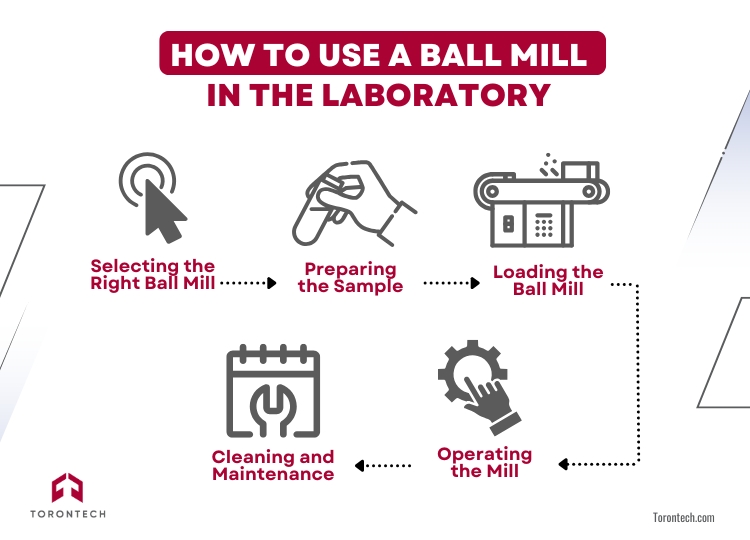

How to Use a Ball Mill in the Laboratory

While ball milling is a straightforward process, following best practices ensures optimal results. Here’s a step-by-step guide to using a ball mill effectively:

1. Selecting the Right Ball Mill

Choose a ball mill that suits your sample size and desired outcomes. For laboratory use, planetary ball mills are often preferred for their compact size and ability to handle ultra-fine grinding. However, keep in mind that ball mill machines come in various types. Be sure to explore and carefully consider the following options:

- Capacity: Choose a ball mill with sufficient volume for your sample size.

- Grinding Media: Use balls made of materials that won’t contaminate the sample, such as ceramic for sensitive applications or stainless steel for general use.

2. Preparing the Sample

- Dry or Wet? Decide whether your material is best suited for dry grinding or if a liquid medium is required to reduce heat and improve dispersion.

- Sample Size: Ensure the sample is appropriately sized for the grinding chamber to prevent uneven milling.

3. Loading the Ball Mill

Add the sample and the grinding media to the chamber. The sample-to-media ratio should balance efficiency and safety. Overloading can reduce the effectiveness of grinding.

4. Operating the Mill

Set the appropriate milling speed and duration. Faster speeds increase impact energy but may generate excessive heat, while longer durations provide finer results. Also, monitor the process periodically to avoid overheating or sample degradation.

5. Cleaning and Maintenance

- After milling, clean the chamber and grinding balls thoroughly to prevent cross-contamination between samples.

- Regular maintenance ensures the longevity of the equipment and consistent performance.

Applications of Ball Milling in Laboratories

Ball milling is a cornerstone for effective sample preparation in laboratories, offering precision, versatility, and consistency. Here’s how it supports various research needs:

1. Grinding and Mixing

Ball mills ensure precise grinding and homogenous mixing of materials, ideal for chemical solutions, ceramics, and pigments. This uniformity enhances the reliability of experimental results.

2. Particle Size Reduction

By reducing larger particles into fine, controlled sizes, ball milling enables the preparation of materials for nanotechnology, pharmaceuticals, and chemical analysis, ensuring compatibility with high-precision instruments.

3. Material Synthesis

Ball mills facilitate the creation of new compounds and mechanical alloys through grinding and blending, unlocking innovative materials with enhanced properties like strength and corrosion resistance.

4. Nanomaterial Development

In nanotechnology, ball milling produces nanoparticles and nanocomposites with unique properties, making it essential for research in electronics, medicine, and environmental protection.

5. Homogenization for Analysis

For accurate testing, ball mills create uniform samples, essential for chemical, thermal, and environmental analysis. This ensures repeatable and precise results across experiments.

6. Specialized Applications

From preparing biomaterials in biomedical research to blending explosives and processing food additives, ball mills adapt to diverse fields with ease and reliability.

Key Considerations for Laboratory Ball Milling

To ensure precise and efficient results with ball milling, laboratories should focus on these critical factors:

1. Milling Parameters

Adjust speed, duration, and media size to achieve the desired particle size and prevent over-grinding. These settings directly influence efficiency and uniformity.

2. Material Properties

Consider the hardness, brittleness, and moisture content of the material, as these factors affect the milling process and guide parameter adjustments.

3. Avoiding Contamination

Use inert grinding media like ceramic or stainless steel and thoroughly clean the equipment after each use to maintain sample integrity.

4. Energy Efficiency

Optimize settings to balance power consumption and productivity, ensuring sustainable and cost-effective operations.

5. Regular Monitoring

Check milling conditions periodically to prevent overheating, excessive wear, or unintended changes to the material.

By addressing these considerations, laboratories can maximize the effectiveness of ball milling while maintaining equipment longevity and reliable results.

Closing Thoughts

A ball mill can be a transformative tool for your laboratory, offering precision, versatility, and reliability for grinding, mixing, and blending materials. Whether you’re preparing samples for analysis or exploring advanced research like nanomaterials, this tool helps you achieve consistent and accurate results while streamlining your workflows.

If you’re ready to enhance your sample preparation process, explore our extensive range of Ball Mills. Designed with modern research needs in mind, these machines combine efficiency with ease of use, providing a reliable solution for your laboratory’s material preparation challenges.

References:

- Piras, C. C., Fernández-Prieto, S., & De Borggraeve, W. M. (2019). Ball milling: a green technology for the preparation and functionalisation of nanocellulose derivatives. Nanoscale Advances, 1(3), 937–947.

- Gou, J., Zhuge, J., & Liang, F. (2012). Processing of polymer nanocomposites. In Elsevier eBooks (pp. 95–119).