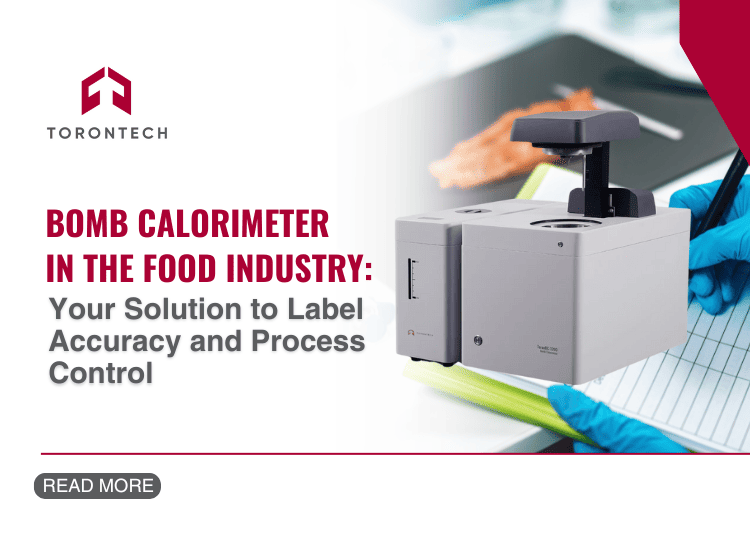

Bomb Calorimeter in the Food Industry: Your Solution to Label Accuracy and Process Control

Bomb calorimeter analysis solves a growing challenge in the food industry: inconsistent or outdated caloric data. Relying only on calculated estimates or outdated Atwater values can lead to labeling inaccuracies, regulatory penalties, or lost consumer trust. This is especially risky when launching new products or reformulating for changing dietary trends. Using this device gives food […]