Measuring carbon and sulfur content accurately is critical in industries such as metallurgy, petrochemicals, and environmental monitoring. Understanding how carbon sulfur analyzers function allows you to optimize material quality, comply with regulations, and enhance process efficiency.

Carbon and sulfur levels influence material properties, making precise analysis important for maintaining product performance. By using a carbon sulfur analyzer, you can achieve reliable results that ensure product consistency and regulatory compliance while also improving the efficiency of your processes.

What Is a Carbon Sulfur Analyzer?

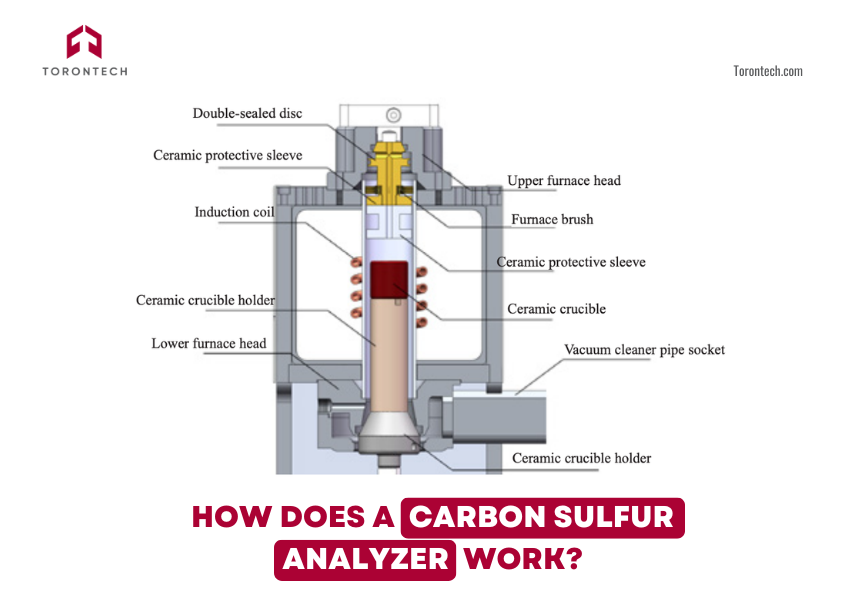

A carbon sulfur analyzer helps you measure the carbon and sulfur content in materials like metals, cement, coal, and petroleum products. It works by burning a sample in an oxygen-rich environment, converting carbon into carbon dioxide (CO₂) and carbon monoxide (CO) and sulfur into sulfur dioxide (SO₂). These gases are then analyzed to determine their exact concentrations.

If you’re working with challenging materials, you may need to add fluxes like tungsten, tin, or copper to ensure complete combustion. The analyzer processes the data and delivers precise results, allowing you to quickly assess material quality and make informed decisions in industrial applications.

How Does a Carbon Sulfur Analyzer Work?

A carbon sulfur analyzer functions by combusting a sample in an oxygen-rich environment, breaking it down into measurable gases. The combustion process ensures complete oxidation, while the generated gases are processed and analyzed using different measurement techniques.

A. Combustion and Gas Flow Process

- High-Frequency Induction Heating: The sample, placed in a ceramic crucible, is rapidly heated to ensure efficient combustion.

- Use of Fluxes: Fluxes like tungsten, tin, or copper may be added to aid combustion, especially for challenging materials.

- Gas Separation: The produced gases pass through a conditioning system to remove unwanted byproducts before analysis.

B. Measurement Methods: Infrared Absorption vs. Gas Chromatography

Once the combustion gases are prepared, the analyzer measures carbon and sulfur concentrations using one of two methods:

- Infrared Absorption: Measures gas concentrations by detecting the amount of infrared radiation absorbed by CO₂ and SO₂. This method is widely used due to its simplicity and cost-effectiveness, though it may have limitations in detecting trace levels due to interference from other gases.

- Gas Chromatography: Separates CO₂ and SO₂ from other gases before detection, increasing measurement precision. This method provides higher sensitivity but requires more complex calibration and is generally more expensive.

Applications of Carbon Sulfur Analyzers

If you work in an industry that requires precise material analysis, you will likely need a carbon sulfur analyzer. These instruments are essential in steel manufacturing, cement production, petrochemical refining, environmental monitoring, and food analysis.

1. Metallurgy and Steel Production

In the steel industry, controlling carbon and sulfur levels is crucial to achieving the right mechanical properties. Carbon influences strength, hardness, and ductility, while sulfur affects brittleness and machinability.

High sulfur content can lead to material defects such as cracks and reduced durability. By using a carbon sulfur analyzer, you can ensure compliance with industry standards and optimize production quality.

2. Cement and Construction Materials

In cement production, sulfur content must be carefully monitored to prevent expansion-related defects that weaken structural integrity.

Excess sulfur can lead to the formation of undesirable compounds, affecting concrete durability. Accurate carbon measurement also helps regulate the burning process in clinker production, ensuring efficiency and consistency in cement quality.

3. Petrochemical and Energy Sector

For the petrochemical industry, monitoring sulfur levels in fuels is necessary to meet environmental regulations and prevent corrosion in pipelines and engines. In coal and coke combustion, carbon analysis is vital for optimizing fuel efficiency and emission control.

A carbon sulfur analyzer enables you to refine fuel quality and improve combustion performance in power plants and industrial boilers.

4. Environmental Monitoring

Industries must track carbon and sulfur emissions to comply with air quality regulations and reduce environmental impact. Carbon sulfur analyzers help measure emissions from industrial plants, ensuring regulatory compliance and sustainable operations.

In environmental research, these instruments are used to analyze soil, sediments, and atmospheric samples, providing critical data on pollution levels and ecological changes.

5. Food Analysis

Carbon and sulfur analysis is increasingly being used in the food industry to assess the composition and quality of food products. The carbon content in food affects nutritional value, energy content, and shelf stability, while sulfur plays a role in preservatives, amino acids, and protein structure.

In food safety, excessive sulfur levels can indicate contamination or unwanted chemical residues. By using a carbon sulfur analyzer, food manufacturers and quality control laboratories can ensure compliance with food safety regulations, optimize ingredient formulations, and maintain consistent product quality.

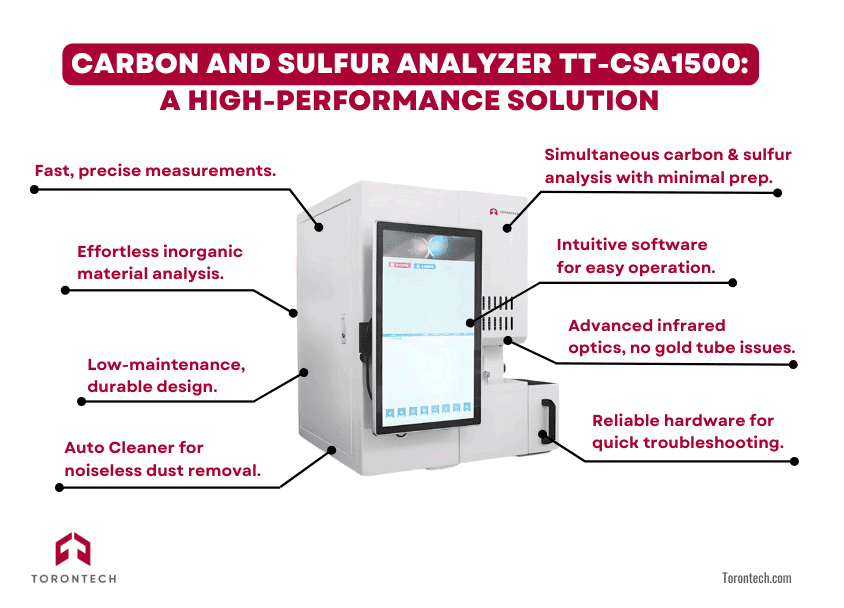

Carbon and Sulfur Analyzer TT-CSA1500: A High-Performance Solution

If you are looking for a high-precision carbon and sulfur analyzer, the TT-CSA1500 offers an advanced solution. This analyzer is equipped with a high-frequency furnace and infrared detection, ensuring rapid and accurate results. It is particularly effective for analyzing metallic substances, ceramics, ores, cement, and clays.

With an adjustable furnace power setting, the our Carbon and Sulfur Analyzer optimizes combustion conditions for different materials, providing reliable and consistent data. The analyzer’s solid-state IR detectors enhance sensitivity and speed while requiring minimal maintenance.

The user-friendly software simplifies the analysis process, allowing you to focus on obtaining results rather than dealing with complex system configurations. Additionally, the Auto Cleaner ensures that dust and debris are removed efficiently, keeping the system running smoothly.

Final Thoughts

Carbon sulfur analyzers are an invaluable tool for industries that require precise elemental analysis. Whether you work in metallurgy, construction, petrochemicals, or environmental science, these instruments help ensure compliance, improve material quality, and optimize production efficiency. By choosing the right analyzer and understanding how it works, you can enhance your analytical capabilities and achieve more reliable results.

If you need a top-tier carbon sulfur analyzer, our TT-CSA1500 is a solution worth considering. Its combination of speed, accuracy, and low maintenance makes it a valuable investment for any laboratory or production setting.

Need more details or have questions? Get in touch with us, our dedicated team is happy to assist you with anything you need.