A digital density meter gives you fast, reliable, and accurate liquid measurement with minimal effort. Whether you’re testing fuel, analyzing beverages, or working in a lab, this tool helps you get consistent results without the guesswork. It’s designed for industries where precision matters: chemical, pharmaceutical, and petroleum sectors all rely on it.

This article breaks down how it works, what to look for, and why it’s a smart addition to your workflow.

What Is a Digital Density Meter?

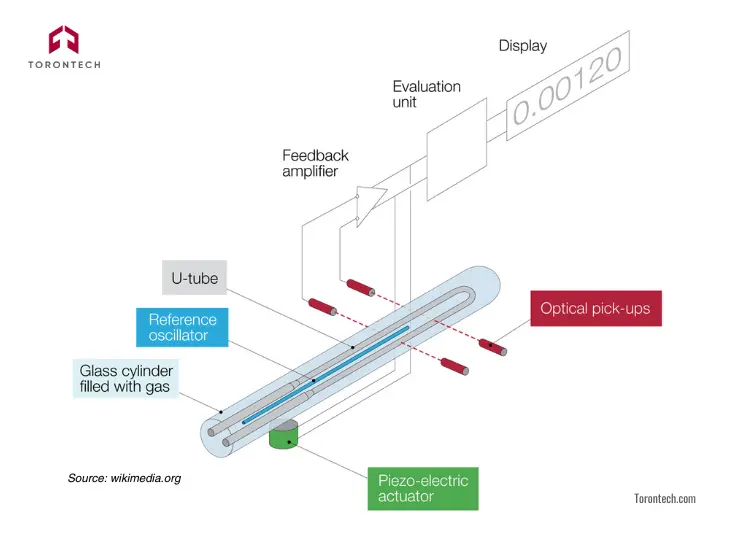

A digital density meter is a smart, electronic device that accurately measures the density of liquids—and in some cases, gases—using automated technology. The most widely used method is the oscillating U-tube technique.

Here, a U-shaped glass tube is filled with your sample, and the device measures how the tube’s vibration frequency changes. That shift is directly related to the sample’s density.

The precision you get is impressive, often displaying results to five decimal places (e.g., 0.00005 g/cm³). This means you can count on consistent data, whether you’re verifying product quality or ensuring compliance with industry standards.

Compared to traditional tools, digital meters are faster and easier to use. You don’t need to interpret visual cues or deal with manual calculations. It’s a reliable way to reduce errors and streamline your testing process in the lab, on the production floor, or out in the field.

How Does a Digital Density Meter Work?

Most devices rely on the U-tube digital density meter method, giving you fast and precise results with minimal effort. Here’s how it works: you inject a small liquid sample into a U-shaped glass tube inside the device. This tube begins to vibrate—usually triggered by a piezoelectric or electromagnetic system.

The frequency of that vibration depends on the mass of your sample. As the density increases, so does the mass inside the tube, which slows down the oscillation. Internal electronics detect this frequency change and calculate the density using built-in calibration constants.

What’s even better is that many digital meters come with automatic temperature control and error detection features. These help you get reliable readings every time without second-guessing the results. Because the process is quick, hands-off, and only needs a tiny sample volume, it’s a perfect fit for busy labs and quality control environments.

Measurement Principle and Methods Used in Digital Density Meters

The oscillating U-tube method is the most common principle used. It works well because it’s fast, precise, and easy to automate. To measure, you simply inject a small liquid sample into the tube.

The system checks itself before each test and can be calibrated using certified density standards. Some models handle multiple samples in one go, saving you time during large testing runs. You can also choose between the density kit standard and advanced setups, depending on your needs.

Key Features to Look for in a Digital Density Meter

When evaluating laboratory density meter options, focus on features that improve workflow and accuracy:

- Digital density meter accuracy with repeatability of 0.0001 g/cm³ or better

- Minimal sample volume to reduce waste

- Automated temperature compensation

- USB, Ethernet, or RS232 connections for data tracking

- Compliance with digital density meter ASTM D4052 and other standards

These features help streamline your process while keeping results consistent.

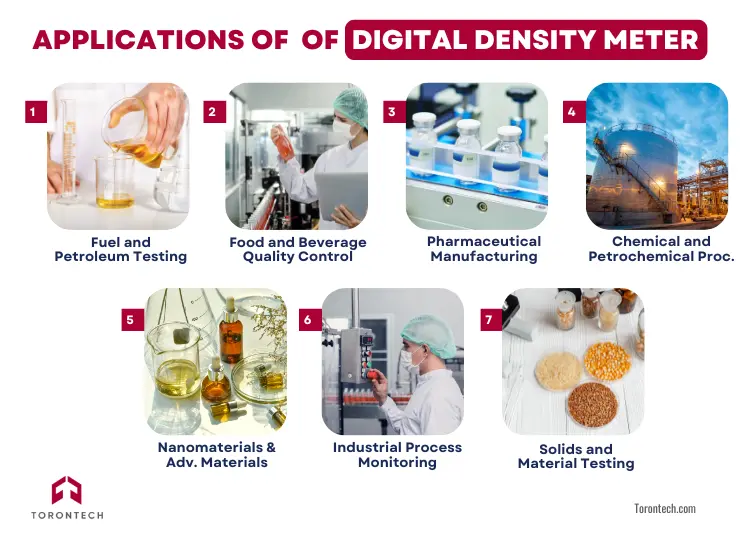

Applications of Digital Density Measurement

Digital density meters are versatile instruments that deliver fast, accurate results. Here’s how you might use one in your industry:

1. Fuel and Petroleum Testing

If you’re working with crude oil, diesel, or lubricants, a digital density meter for fuel helps ensure compliance with industry standards like ASTM D4052. You can use it to measure API gravity, detect inconsistencies, or optimize blending operations for better performance and efficiency.

2. Food and Beverage Quality Control

In this sector, digital density meters measure sugar content (Brix), alcohol concentration, or total solids. Whether you’re testing milk, soft drinks, fruit juice, beer, wine, or sake, this tool helps you maintain product consistency and taste across every batch.

3. Pharmaceutical Manufacturing

Precision is critical in pharma. Digital meters confirm the density of active ingredients and finished products, supporting quality assurance and regulatory compliance. They’re commonly used during formulation, raw material inspection, and final product testing.

4. Chemical and Petrochemical Processing

You can monitor the concentration of etching solutions, plating baths, or pickling acids using digital density meters. They’re also used in R&D to fine-tune additives, emulsifiers, and chemical formulations, helping you develop better products.

5. Cosmetics and Aroma Development

In cosmetic labs or fragrance manufacturing, accurate density readings help control consistency during formulation. Whether you’re mixing serums or developing scents, knowing the precise concentration makes production smoother.

6. Industrial Process Monitoring

For continuous measurements, digital density meters integrate directly into pipelines or reactors. They’re useful for detecting product interfaces, mixing levels, or reaction endpoints in real time, particularly in industries like brewing, mineral processing, and pharmaceuticals.

7. Solids and Material Testing

Beyond liquids, some high-end meters also support density checks for solids. This is useful in sectors like rubber, glass, ceramics, and metals where understanding density is key for quality control and product development.

With so many uses, it’s easy to see why these instruments are trusted across industries for both routine and specialized testing.

Want a deeper dive into the science and broader uses of densimeters? Explore our detailed article here.

Digital Density Meter vs. Traditional Hydrometer

A traditional hydrometer relies on buoyancy and visual readings. In contrast, digital meters are fully automated and reduce operator error. They also provide results faster and with greater repeatability.

Here’s how they compare:

- Accuracy: Digital systems deliver tighter tolerances

- Ease of use: No manual readings or calculations

- Speed: Quick start-up and instant results

- Durability: Fewer moving parts means less wear

That’s why more professionals are turning to high density digital solutions.

Benefits of Using a Digital Density Meter

A digital density meter gives you a faster, cleaner, and more reliable way to measure liquids. You don’t need much training or setup, and the results are ready in seconds. Whether you’re checking alcohol levels, specific gravity, or sugar content, the process is simple and efficient.

Here’s why many labs and production teams rely on these tools:

- High accuracy and repeatability, even with small sample volumes (as low as 0.3 ml)

- Quick measurements, so you can keep up with tight schedules

- Built-in temperature control for stable and precise readings

- Digital readouts and easy data export to your LIMS or records

- Minimal sample handling reduces the chance of human error

- Easy maintenance keeps downtime low

If you’re dealing with frequent testing or tight production windows, high density meters offer the speed and dependability your process needs

Factors to Consider Before Buying

Before picking a model, think about how and where you’ll use it. Key considerations include:

- Type of liquid (viscous, corrosive, volatile)

- Volume of daily samples

- Need for compliance with digital density meter ASTM D4052

- Interface and data-sharing needs

- Available budget and service support

Also, decide whether a basic system or density kit standard and advanced suits your setup better.

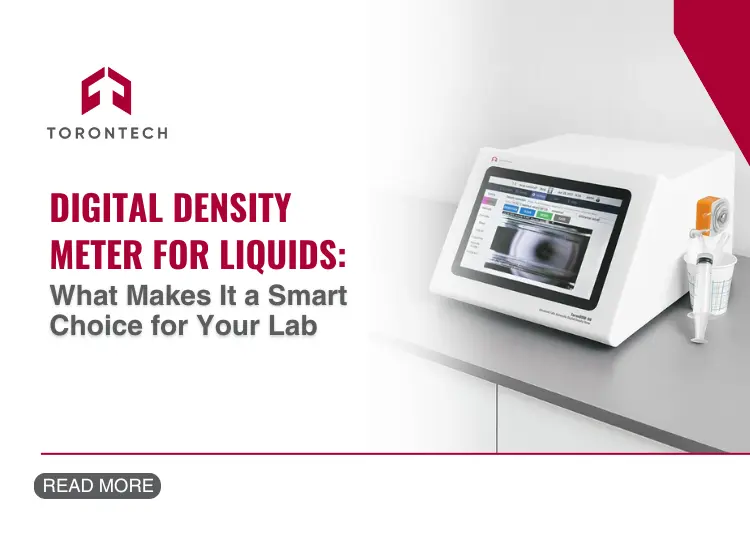

Introducing the ToronDDM-Series by Torontech: Smart Density Testing Made Simple

If you need fast, reliable, and compliant liquid testing, the ToronDDM-Series from Torontech is built to meet those demands. Whether you’re testing fuel blends, pharmaceutical ingredients, or alcoholic beverages, this digital density meter for liquids delivers lab-grade accuracy with user-friendly automation.

Each unit in the ToronDDM-Series uses the proven oscillating U-tube digital density meter method. That means you get highly repeatable results with minimal sample volume. These analyzers support a wide range of industries including pharma, petrochemicals, chemicals, food and beverage, and research labs.

Key Features You’ll Appreciate:

- High-resolution touchscreen interface

- Automatic Peltier-based temperature control

- Real-time bubble detection with HD camera

- USB and RS232 connectivity for data transfer

- Four-level user access for data integrity and 21 CFR Part 11 compliance

- Support for multiple international standards, including ASTM D4052

Choose the Right Model for Your Needs:

- ToronDDM-50: A dependable automatic model for general lab testing

- ToronDDM-70: Fully automatic with enhanced precision and complete CFR compliance

- ToronDDM-90: Ideal for high-viscosity samples and extended temperature control (up to 85℃), with advanced data capacity

All models feature density, alcohol concentration, and custom formula testing with resolution as fine as ±0.00001 g/cm³ and accuracy up to ±0.00008 g/cm³. You also get PDF and Excel export, Wi-Fi printing, and MD5-protected files for secure data handling.

Whether you’re running daily quality control checks or conducting high-level research, Torontech’s digital density analyzer lineup delivers consistent results with the automation and compliance your lab requires.

Watch our demonstration to see how the ToronDDM-Series delivers precise results in real lab conditions:

Final Thoughts

A digital density meter gives you the accuracy and speed you need to keep your testing process efficient and dependable. Whether you’re monitoring fuel blends, developing chemical formulas, or ensuring product quality in the lab, the right tool can make all the difference.

If you’re looking to upgrade your equipment or simply streamline your workflow, the ToronDDM-Series from Torontech offers a flexible, compliant, and user-friendly solution.

Ready to explore more? Check out our full range of digital density meters to find the right fit for your application.

Still unsure or need expert advice? We’re happy to help. Contact us anytime for a consultation, our team is here to support your decision.