An optical fiber cable is a cable containing one or more optical fibers that are used to carry light. The optical fiber elements are typically individually coated with plastic layers and contained in a protective tube suitable for the environment where the cable will be deployed.

Optical fiber consists of a core and a cladding layer, selected for total internal reflection due to the difference in the refractive index between the two. In practical fibers, the cladding is usually coated with a layer of acrylate polymer or polyimide.

This coating protects the fiber from damage but does not contribute to its optical waveguide properties. Individual coated fibers then have a tough resin buffer layer and/or core tube(s) extruded around them to form the cable core. Several layers of protective sheathing, depending on the application, are added to form the cable. Rigid fiber assemblies sometimes put light-absorbing (“dark”) glass between the fibers, to prevent light that leaks out of one fiber from entering another.

This reduces cross-talk between the fibers, or reduces flare in fiber bundle imaging applications Optical fibers are very strong, but the strength is drastically reduced by unavoidable microscopic surface flaws inherent in the manufacturing process.

The initial fiber strength, as well as its change with time, must be considered relative to the stress imposed on the fiber during handling, cabling, and installation for a given set of environmental conditions. There are three basic scenarios that can lead to strength degradation and failure by inducing flaw growth: dynamic fatigue, static fatigues, and zero-stress aging.

Torontech offers a wide range of physical testing machines to evaluate mechanical properties of optical fiber cables:

Optical Fiber Cable Tensile Testing Machine – Indoor Cable

Torontech’s Tensile & Crush Series (for Bow Type Cables) series of Optical Cable Testing machines are designed specifically for indoor optical cables to apply tensile force on indoor optical cables; it also has an extensometer to measure the cable elongation for optical cable under tension.

In Tensile test cable sample is wound over the approximate sized sheave, pulled at a specific rate until a pre-determined tension is applied. The test cable is further laid to rest under tension as per detail specifications, and then the attenuation and fiber length are measured.

Optical Fiber Cable Tensile Testing Machine – Outdoor Cable

Torontech’s TT-OFCT-OD Optical Fiber Cable Tensile Testing Machine is designed in accordance to IEC-60794-1 Method E1 for tensile testing of outdoor Optical Fiber Cables, this measuring method applies to optical fiber cables which are tested at a particular tensile strength in order to examine the behavior of the attenuation and/or the fiber elongation strain as a function of the load on a cable which may occur during installation. This method is intended to be non-destructive (the tension applied shall be within the operational values).

Optical Fiber Cable Abrasion Testing Machine

The Optical Fiber Cable Abrasion Testing Machine TT- OFCA is designed to determine the ability of an optical fiber cable sheath and markings to resist abrasion.

Optical Fiber Cable Crush & Cut through Testing Machine

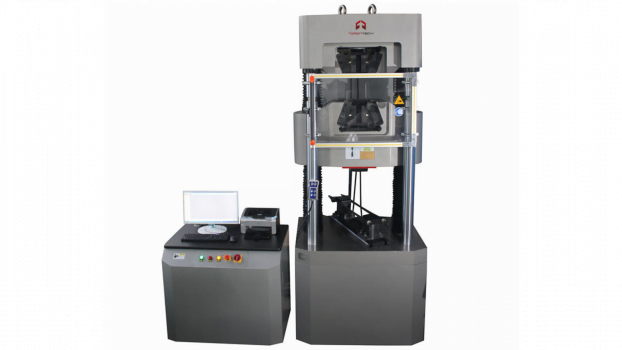

Torontech’s Optical Fiber Cable Crush & Cut through Testing Machine complies with employs an IEC-60794-1-2 Method E3/E12 to perform compression (Crush) test on optical cables.

Cable is laid to rest under compression as per detailed specifications, and then the attenuation of fiber optics is measured. It employs servo-controlled system to apply compressive force on the cable in constant speed and maintains the compression force in specified period.

The plate is mounted on the bottom of moveable crosshead which allows a sample of cable to be crushed between a flat steel base plate and movable steel plate which applies the crushing force uniformly over the length of the sample. Learn more

Optical Fiber Cable Repeated Bending Tester

Optical Fiber Cable Repeated Bending Testing Machine is used to determine the ability of a fiber optic cable to withstand repeated bending (cyclic flexing).

Optical Fiber Cable Impact Testing Machine

The Optical Fiber Cable Impact Testing Machine TTOFCRB Series allows a cable sample to be bent backwards and forwards at an angle of 180° by bending extreme ends of cables at 90° in opposite directions, while the sample is subjected to a tensile load.

The bending arm is designed to hold the cable securely during the entire test, without crushing the optical fibers or inducing optical loss. The bending radius is controlled by replaceable cushioning reels, chosen to match the cable bending radius. The machine is capable of cycling at a rate of 30 cycles per minute. Learn more

Optical Fiber Cable Torsion Tester

Optical Fiber Cable Torsion Testing Machine is used to determine the ability of optical fiber cable to withstand mechanical twisting. This machine is specially designed in accordance with IEC-60794-1-2-E7. Learn more

Optical Fiber Cable Flexibility Testing Machine

Torontech’s TT-OFFT Series Optical Cable Flexing Testing Machine determines the ability of an optical fibre cable to withstand repeated flexing for elevator cable and similar application. The test confirms to IEC 60794-1-2-E8 standard

Designed with pulleys having a semicircular shaped groove for circular cables and a flat groove for flat cables. Restraining clamps are fixed so that the pull is always applied by the weight from which the carriage is moving away. Learn more

Optical Fiber Cable Kink Testing Machine

Optical Fiber Cable Kink Testing Machine is used to determine the loop diameter at the onset of the kinking of an optical fiber cable in accordance with IEC-60794-1-2-E10. The sample length shall be sufficient to carry out the specified test. The diameter of the loop shall be reduced to the onset of kinking by pulling slowly on the two ends.

The forces at the bottom of the loop shall be applied in one plane. Unless otherwise specified, the conditions for testing shall be in accordance with standard atmospheric conditions. Concluding no kink should occur. Learn more

Optical Fiber Cable Temperature Cycling Chamber

The Optical Fiber Cable Temperature Cycling Chamber TT-TCC is designed to apply temperature cycling on optical fiber cables in order to determine the stability behavior of the attenuation of cables submitted to temperature changes. It features large test chamber, precise temperature control as well as low-temperature fluctuations.

Changes in the attenuation of optical fibre cables which may occur with changing temperatures are generally the result of buckling or tensioning of the fibres resulting from differences between their thermal expansion coefficient and the coefficients of the cable strength and jacketing members. Test conditions for temperature-dependent measurements shall simulate the worst conditions.

This test can be used either for monitoring cable behavior in the temperature range which may occur during storage, transportation and usage or to check, in a selected temperature range (usually wider than that required for the above-mentioned case), the stability behavior of the attenuation connected to a substantially micro bend-free situation of the fibre within the cable structure.

Besides the above-mentioned machines, Torontech also supports various unique requirements our clients may have. Our range of machinery is highly customizable and our team of experts go above and beyond to ensure value delivery.

To explore our full range of Optical Fiber Cable Testing Equipment, click here. To book a discovery call our experts, contact us at sales@torontech.com.