Precision and efficiency are vital in materials processing, yet many industries struggle to find consistent grinding results with the utmost level of precision. The need for a versatile and powerful instrument is evident, and that’s where Planetary Ball Mills comes into play. These innovative grinding machines have the potential to solve the persistent problem of achieving precise and efficient materials processing across various industries.

One of the critical challenges in materials processing is achieving the desired particle size while maintaining consistency. Traditional grinding methods often fall short, leading to inconsistent results and wasted resources. However, the Planetary Ball Mill offers a game-changing solution. With their ability to grind down materials to nano-sized particles quickly and efficiently, these mills provide a level of previously unattainable precision.

The versatility of these mills is what sets them apart. This instrument is ideal for grinding (dry or wet) and blending a wide range of sample types, from soft to hard, and brittle to fibrous, making them suitable for diverse industries such as medicine, chemical synthesis, and geology. Moreover, their customizable speed ratio allows users to adapt the grinding process to the specific characteristics of their samples, ensuring optimal performance and desired particle size distribution.

By harnessing the power of Planetary Ball Mills, industries can overcome the challenges of inconsistent results and wasted resources in materials processing. These mills offer a precise and efficient solution, unlocking innovation and transforming how we approach materials processing in various sectors. With their versatility and customizable features, these mills provide a reliable and effective instrument to meet the demands of modern industries seeking excellence in materials processing. The question is, how can you find the right Planetary Ball Mill Supplier for your industry?

The Advantages of Planetary Ball Mills

The utilization of Planetary Ball Mill offers a multitude of advantages, making them indispensable in various industries. Here are the key benefits associated with these advanced milling devices:

1. High Precision Grinding

Planetary Ball Mills provide precise and controlled grinding, reducing uniform particle size. This is crucial for industries where consistency in sample quality is paramount.

2. Versatility in Material Processing

These mills are highly versatile and capable of handling various materials, from soft and brittle to hard and fibrous substances. The Planetary Ball Milling Process is adaptable, making it suitable for diverse applications.

3. Efficient Mixing and Homogenization

The uniform grinding achieved by these mills ensures sample homogeneity, a critical factor in obtaining accurate and reliable test results. Consistent sample quality is essential for industries relying on precise analysis.

4. Short Processing Time

The unique design and efficient working principle of Planetary Ball Mills lead to shorter processing times. This is especially beneficial for industries requiring rapid, time-sensitive testing and analysis are paramount.

5. Minimal Contamination

Sealed grinding jars reduce the risk of contamination during the milling process, ensuring the purity of the final sample. This is particularly critical in industries where contamination can compromise test results.

6. Scale-Up Capability

These mills offer scalability, allowing for the Planetary Ball Milling Process of small and large quantities of material. This scalability is advantageous for industries with varying testing needs.

7. Ease of Operation

The Planetary Ball Milling Process is made easy because this instrument is user-friendly, with straightforward operation and maintenance procedures. This ease of use enhances overall efficiency in the testing and analysis processes.

8. Advanced Technological Features

In the context of Torontech’s commitment to cutting-edge testing technology, our Ball Mills incorporates advanced features to meet the evolving demands of industries for robust, sophisticated, and reliable equipment.

9. Cost-Effective with an Excellent Price

Our Planetary Ball Mill offers a cost-effective solution at an excellent price. This means your industry can acquire a high-quality product competitively, providing value for their investment. These Ball Mills make it an attractive option for those seeking cost-effective grinding solutions without compromising performance or durability.

By leveraging these advantages, Torontech ensures that its Planetary Ball Mills are at the forefront of providing high-performance solutions for industries relying on advanced testing technologies.

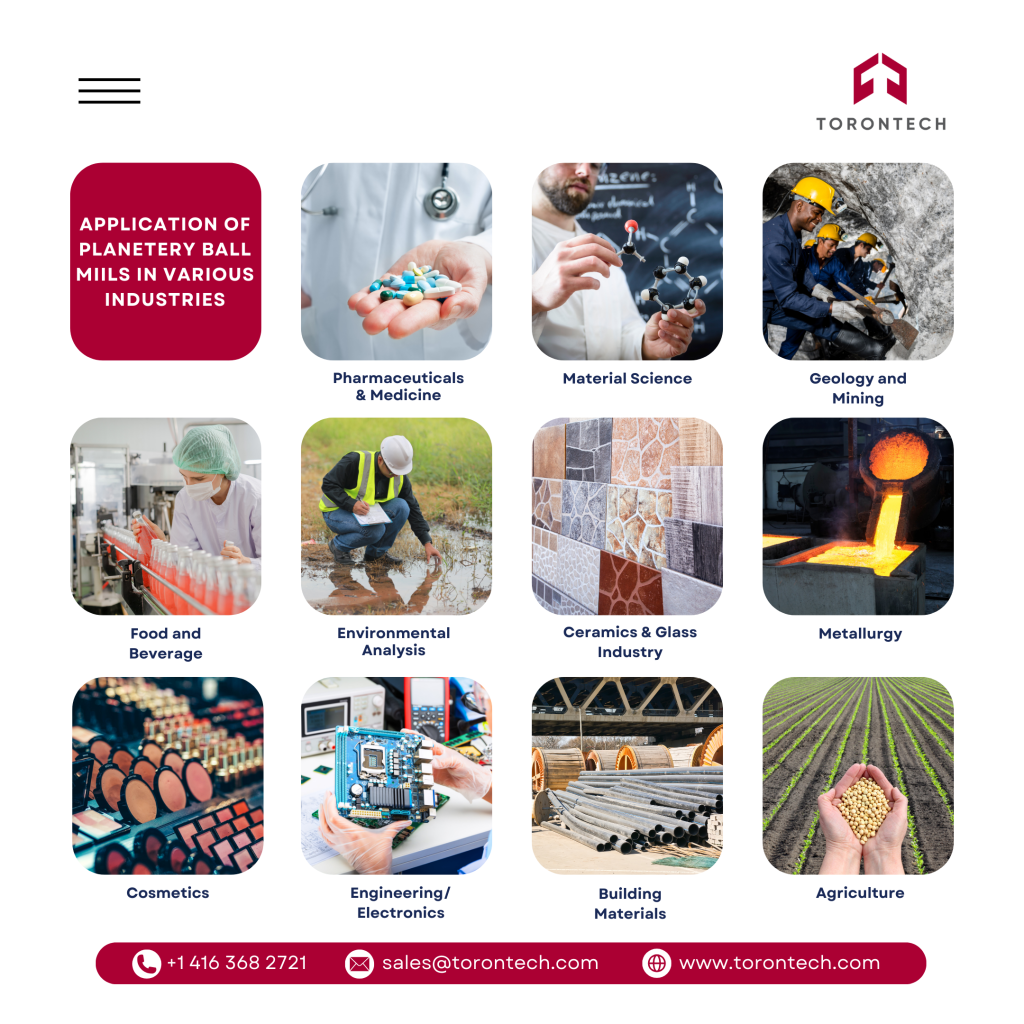

Planetary Ball Mills Play a Crucial Role In a Wide Range of Industries

Planetary Ball Mill find applications across diverse industries due to their versatility and precision in material processing. As a Planetary Ball Mill Supplier, we inform about several industries that can benefit from the use of this advanced testing instrument:

1. Pharmaceuticals & Medicine

Planetary Ball Mills are crucial in pharmaceutical and medicine research and development for grinding and homogenizing pharmaceutical compounds. Their precision is essential in ensuring consistent particle size for drug formulation.

2. Materials Science

In materials research, these mills play a vital role in grinding and blending materials to develop new materials, composites, and nanomaterials. The controlled grinding process is vital for achieving desired material properties.

3. Geology and Mining

The Planetary Ball Mill is employed in geological and mining research for grinding and homogenizing geological samples, ores, and minerals. Their versatility allows for processing various types of geological samples, rocks, and minerals. This aids in sample preparation for accurate analysis and characterization.

4. Food and Beverage

The food industry uses Planetary Ball Mills to grind and mix ingredients to achieve desired textures and consistency. Their use ensures uniformity in food processing.

5. Environmental Analysis/Resource Recovery

Laboratories involved in environmental analysis use Planetary Ball Mill for sample preparation. The mills aid in grinding and homogenizing environmental samples for accurate analysis of contaminants. They also contribute to resource recovery by facilitating precise analysis of materials for recycling and environmental monitoring.

6. Ceramics and Glass Industry

These mills are integral to grinding and blending raw materials in the glass and ceramics industry. Their ability to achieve uniform particle size is essential for producing high-quality glass and ceramic products.

7. Metallurgy

Industries dealing with metal alloys and metallurgical research utilize Planetary Ball Mill for grinding and blending metal powders, ensuring the uniformity of the final product.

8. Cosmetics

In the cosmetic industry, these mills grind and blend cosmetic ingredients to achieve desired textures and formulations.

9. Engineering/Electronics

Planetary Ball Mills are utilized for grinding and homogenizing electronic components, advanced materials, and alloys. Their precision and ability to handle a variety of materials make them valuable in engineering applications.

10. Building Materials

In producing building materials like cement, these mills play a role in grinding raw materials to achieve the desired particle size distribution. This is crucial for ensuring the quality and strength of the final construction materials.

11. Agriculture

In agriculture, these mills can be employed for various purposes, including grinding and homogenizing plant samples for research and quality control. The versatility of Planetary Ball Mill makes them adaptable to different agricultural applications.

In each of these industries, Torontech’s commitment to advanced testing technology ensures that our this Ball Mills are designed to meet specific needs and challenges. Whether achieving precise grinding in electronic components or ensuring uniformity in building materials, our product is tailored to provide efficient and reliable solutions for diverse applications.

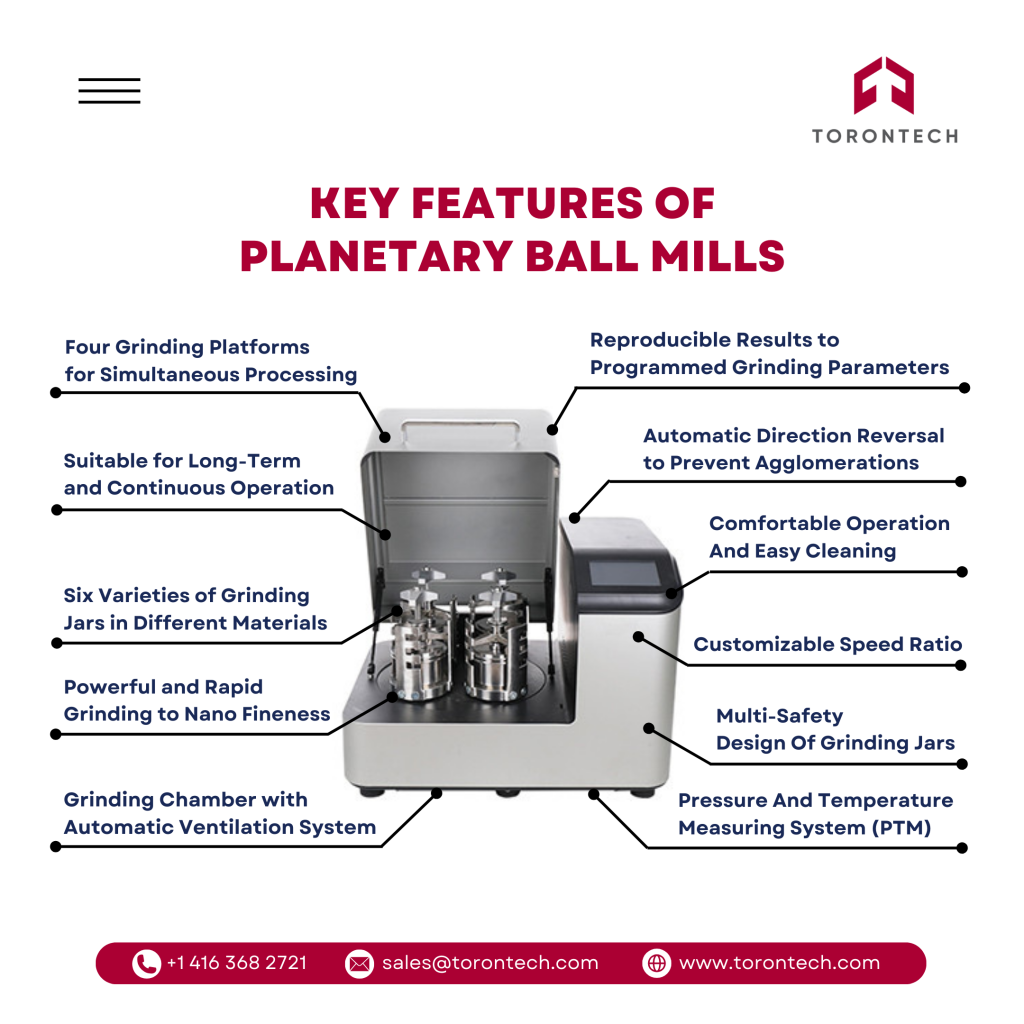

Key Features of Torontech’s Planetary Ball Mills

Torontech’s Planetary Ball Mill features a range of key features that set them apart as cutting-edge solutions for advanced testing technology. Here are the prominent features of our product:

1. Automatic Direction Reversal to Prevent Agglomerations

Our planetary ball mills are equipped with an automatic direction reversal feature. This functionality prevents agglomerations and ensures efficient grinding. The materials are evenly distributed and effectively ground by periodically reversing the rotation direction, minimizing the risk of samples sticking or clumping together.

2. Powerful and Rapid Grinding to Nano Fineness

Our planetary ball mill are designed for robust and rapid grinding. They utilize high-impact energy to achieve nano fineness in a short amount of time. This capability is crucial for industries that require fine-grinding materials to achieve specific particle sizes and surface characteristics.

3. Suitable for Long-Term and Continuous Operation

Our mills are built for long-term and continuous operation. They are engineered with durable components and robust construction to withstand demanding industrial environments. This feature ensures that the mills can handle extended operation times, making them suitable for research and large-scale production processes.

4. Reproducible Results to Programmed Grinding Parameters

Our planetary ball mills offer reproducible results due to the ability to program and control grinding parameters. You can set and adjust parameters such as grinding time, speed ratio, and rotation direction, allowing for precise control over the grinding and Planetary Ball Milling process. This feature ensures consistent and reproducible results, which is critical for research and quality control applications.

5. Grinding Chamber with Automatic Ventilation System

The grinding chamber of our planetary ball mill is equipped with an automatic ventilation system. This system helps dissipate heat generated during grinding, preventing overheating and ensuring optimal operation. It promotes efficient cooling and maintains a controlled temperature environment within the chamber.

6. Four Grinding Platforms for Simultaneous Processing

Our this ball mills feature four grinding platforms, allowing for the simultaneous processing of multiple samples. This capability increases productivity and efficiency, as you can grind different samples or materials concurrently, saving time and resources.

7. Six Varieties of Grinding Jars in Different Materials

We offer six varieties of grinding jars for our planetary ball mills, each made from different materials, with volumes ranging from 12ml to 4000ml. These options allow you to choose the most suitable jar based on the specific requirements of your samples. The selection includes jars made of stainless steel, agate, alumina, zirconia, and tungsten carbide, offering compatibility with a wide range of materials and ensuring optimal grinding performance.

8. Multi-Safety Design Of Grinding Jars

Grinding jars in planetary ball mill have safety measures for colloid grinding, including secure closure mechanisms for gas-tight and dust-proof environments, ensuring safe operation. The safety closure device seals during colloid grinding to prevent the escape of overpressure gas. An aeration lid allows for gas import/export and additional safety protection. These safety features maintain high-level gas tightness, preserving the integrity of grinding results.

9. Customizable Speed Ratio

Planetary ball mills offer adjustable speed ratios (1, 2, or 4 grinding stations) to match sample characteristics. They provide a wide selection of high-quality grinding materials and allow flexible combinations of grinding balls for unique crushing and grinding requirements. The mills generate high-impact energy, enabling rapid sample grinding.

10. Comfortable Operation And Easy Cleaning

These mills prioritize user comfort and safety with intelligent security locks and ergonomic design. They feature user-friendly program settings for grinding time and autonomous operation. The mills have efficient, maintenance-free drive systems that maintain constant speed during continuous operation. Built-in high-power fans effectively cool the motor during grinding.

11. Pressure And Temperature Measuring System (PTM)

The Planetary Ball Mill incorporates a pressure and temperature measuring system (PTM) to monitor and record various Planetary Ball Milling Processes and reactions within the grinding jars, including temperature and pressure changes. This system enhances grinding quality and enables precise analysis of results by providing real-time data during operation.

By incorporating these key features into our Planetary Ball Mills, we provide a reliable and efficient solution for materials processing. Experience the power of our mills and unlock innovation in materials processing.

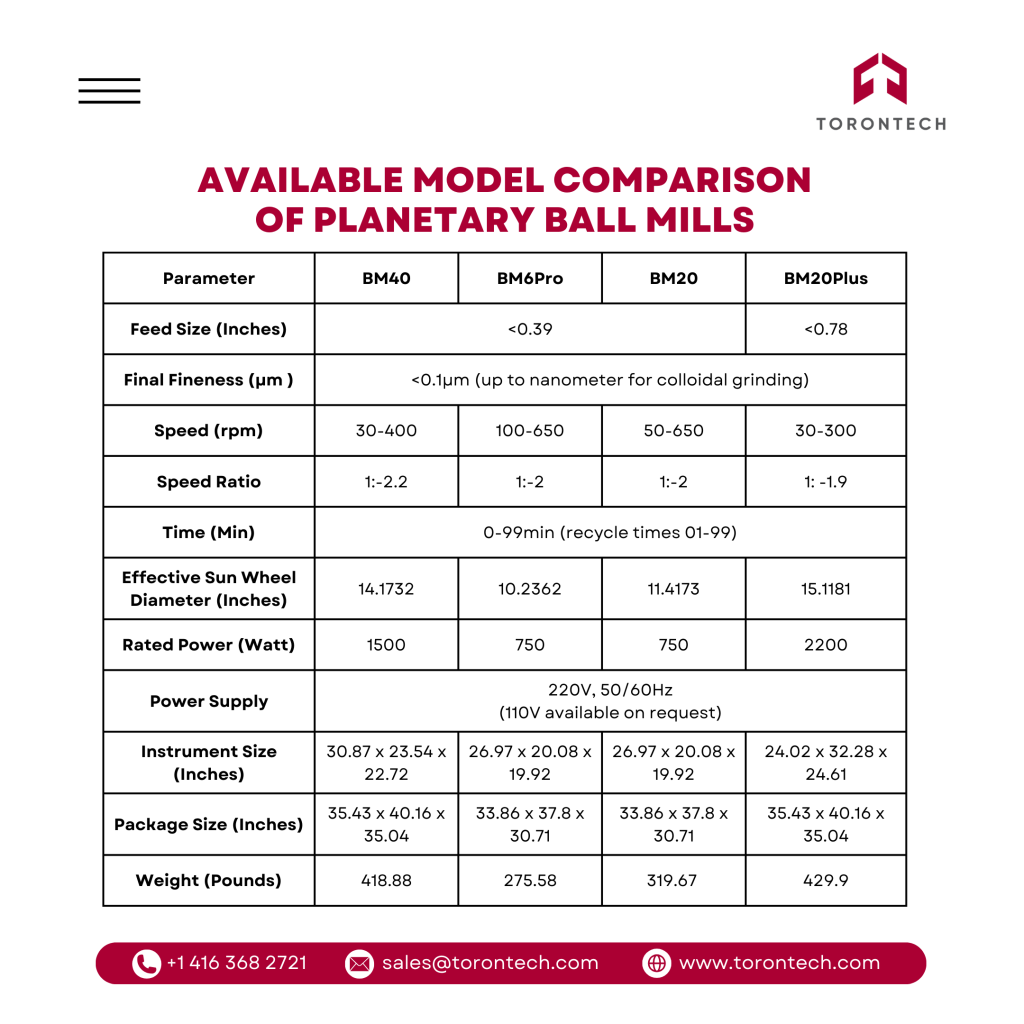

Choosing The Right Model of Planetary Ball Mills for Your Industries

Choosing the right Planetary Ball Mill model is crucial for industries seeking precision, efficiency, and reliability in their material processing and testing applications. Torontech as a Planetary Ball Mill Supplier, provides some models — BM40, BM6Pro, BM20, and BM20Plus. This format allows for a quick and comprehensive comparison of key features across these advanced testing instruments.

For industries grappling with the decision of which Planetary Ball Mill model to select, consider the following guidelines:

- Application Specifics: Assess your industry’s specific material processing needs. Different models cater to varying feed sizes, final fineness requirements, and speed ranges.

- Throughput Requirements: Evaluate the expected workload and Planetary Ball Milling Process speed needed. Models with higher RPMs may be more suitable for faster material processing.

- Space and Power Constraints: Consider your facility’s available workspace and power supply. Choose a model that fits both spatially and electrically.

- Sample Size and Type: Tailor your choice based on the characteristics of the materials you’ll be working with. Some models are better suited for specific sample types.

- Budget Considerations: While all models offer advanced features, align your choice with budget constraints. Determine the optimal balance between performance and cost.

By carefully weighing these factors, industries can decide on the Planetary Ball Mill model that best aligns with their unique requirements, ensuring efficient and precise material processing.

Conclusion: Embrace the Future of Materials Processing with Our Planetary Ball Mills

Innovation in materials processing is crucial for the progress of industries worldwide. The versatility of Planetary Ball Mills has proven to be a game-changer, delivering precision, efficiency, and consistent results in grinding applications. As you strive to enhance your materials processing capabilities, we invite you to consider Torontech as a Planetary Ball Mill Supplier.

With our cutting-edge technology and unwavering commitment to excellence, we have developed these mills that cater to the diverse needs of industries spanning medicine, geology, and more. Our mills offer unparalleled precision, enabling you to achieve the desired particle size with exceptional consistency, ensuring your products meet the highest quality standards, and fulfilling all the necessary technical criteria for achieving colloidal grinding.

Furthermore, our ball mills are designed for user-friendly operation and long-term reliability. With customizable features, intuitive controls, and efficient cleaning mechanisms, these mills streamline your workflow and boost productivity. We understand the demands of your industry, and our goal is to provide you with a solution that not only meets but surpasses your expectations.

Unlock the potential of materials processing innovation with our Planetary Ball Mills and experience the transformative impact they can have on your operations. Our dedicated team is ready to support you at every stage, offering expert guidance and ensuring our solution aligns seamlessly with your specific requirements.