Plastic waste has become a pressing global issue, posing significant challenges to our environment and ecosystems. Addressing this issue requires innovative solutions and technologies that enable the efficient recycling of plastic materials. In this regard, Plastic Pulverizer Machines emerge as a pivotal tool in the journey towards effective plastic recycling.

The plastic recycling industry plays a crucial role in mitigating the environmental impact of plastic waste. By diverting plastics from landfills and incinerators, recycling not only conserves natural resources but also reduces greenhouse gas emissions and pollution. However, traditional recycling methods often face challenges in processing certain types of plastic waste, leading to limitations in recycling rates and effectiveness.

Amidst the challenges of plastic recycling, Plastic Pulverizer Machines offer a ray of hope. These sophisticated machines are designed to pulverize plastic materials into fine particles or powder form, unlocking new possibilities for the recycling of diverse plastic waste streams. By breaking down plastics into smaller, more manageable sizes, Pulverizer Machines overcome barriers encountered by conventional recycling methods, thus expanding the scope and efficiency of plastic recycling operations.

Whether it’s post-consumer plastics, industrial scraps, or complex plastic composites, Pulverizer Machines offers a versatile solution for transforming diverse plastic materials into valuable resources. In this blog post, we will explore the intricacies of Plastic Pulverizer Machines, their applications, benefits, and considerations for choosing the right machine for your recycling needs.

What is a Plastic Pulverizer Machine?

A plastic pulverizer machine, also known as a plastic mill or grinder, is a mechanical device used to grind plastic materials into fine powders or particles. It is commonly used in the plastic recycling industry, plastic pipe profile manufacturing, and plastic modification to reduce the size of plastic waste for further processing or to facilitate the production of plastic products.

They are known for their energy efficiency, cost-effectiveness, and ability to produce high-quality, consistent particle sizes. Some key features of plastic pulverizer machines include low electricity consumption, reliable output, and minimal maintenance requirements. They are also designed to be easy to clean and have a wide range of applications.

Plastic Pulverizer Machines are available in various sizes and capacities, depending on the specific requirements of the application. They can be used to process different types of plastic materials, including semi-rigid, brittle, and impact-resistant materials.

These machines play a significant role in addressing the challenge of plastic waste management by enabling the recycling and reuse of plastic materials, thereby reducing environmental pollution and conserving resources.

For businesses in the plastic industry or those dealing with plastic waste management, investing in a quality plastic pulverizer machine can offer significant benefits in terms of cost savings, efficiency, and sustainability.

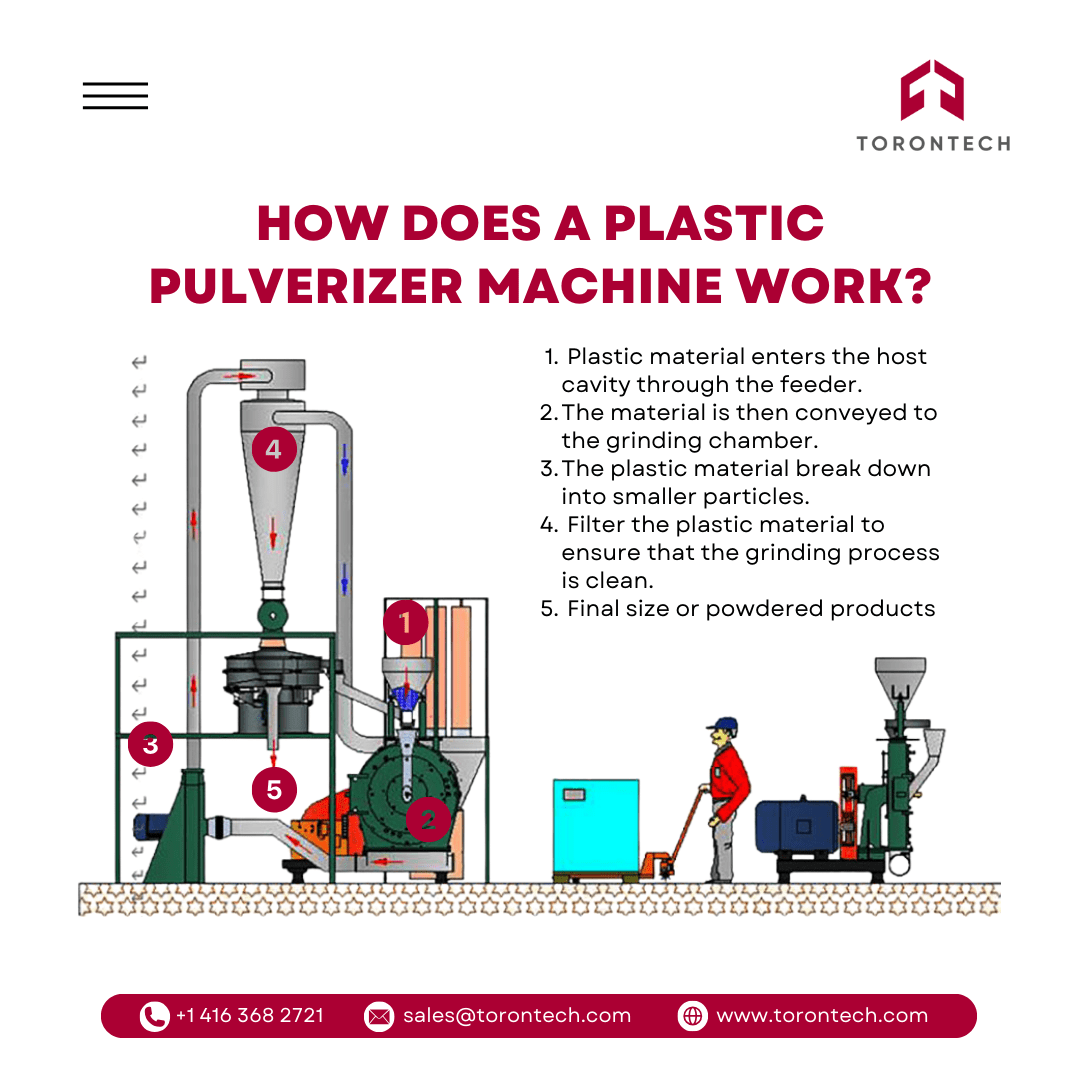

How does a Plastic Pulverizer Machine Work?

A plastic pulverizer machine works by using a series of rotating blades or hammers to crush and grind plastic materials into smaller pieces. The process begins with the plastic material being fed into the machine through a hopper or feeder.

The material is then conveyed to the grinding chamber, where it is subjected to high-speed rotating blades or hammers on the rotor. These blades or hammers break down the plastic material into smaller particles, which are then expelled through a discharge opening. The size of the particles produced can be adjusted by changing the speed of the blades or hammers or by using different types of cutting tools.

The machine can be equipped with various filters and dust collectors to ensure that the grinding or crushing process is clean and that the resulting powder is free of impurities. Plastic pulverizer machines are designed to be utilized for shredding LDPE, HDPE, UPVC, PC, and various other types of plastics.

The operation of a plastic recycling pulverizer machine is typically controlled by a motor and a drive system, which can be manually or automatically adjusted to control the speed and power of the grinding process. The machine may also include features such as a cooling system to prevent overheating, a dust collection system to minimize pollution, and a maintenance-friendly design for easy cleaning and replacement of cutting tools.

What is the Difference Between Grinder and Pulverizer?

The terms “grinder” and “pulverizer” are often used interchangeably, but there are some differences between the two. Both are mechanical devices used for grinding various materials, but the main difference lies in the size of the particles produced.

A grinder typically produces larger particles, while a pulverizer produces smaller particles. This is because a pulverizer uses high-speed rotating blades or hammers to crush and grind materials into a fine powder, while a grinder may use slower-moving blades or a different grinding mechanism to produce larger particles.

In the context of plastic pulverizer machines, the machine is designed to grind plastic materials into smaller particles, which can be used as raw materials in the production of new plastic products or as fillers in various chemical products. The pulverized plastic powder can be made into various sizes, depending on the application and the type of plastic material being processed.

Please check the table below for more information about the difference between a grinder and a pulverizer.

| Aspect | Grinder | Pulverizer |

| Operation | Rotating abrasive surfaces or blades | High-speed rotating blades or hammers |

| Purpose | Coarse grinding or shredding | Fine grinding or pulverizing |

| Materials | Wide range including wood, plastics, metals | Harder materials like ores, chemicals, plastics |

| Output Size | Larger particle sizes | Very fine particles or powders |

| Industries | Food processing, woodworking, metalworking | Plastic Recycling, pharmaceuticals, mining |

In summary, a grinder is a general term for a mechanical device used for grinding various materials, while a pulverizer is a specific type of grinder that produces very fine particles.

What is a Plastic Pulverizer Machine Used For?

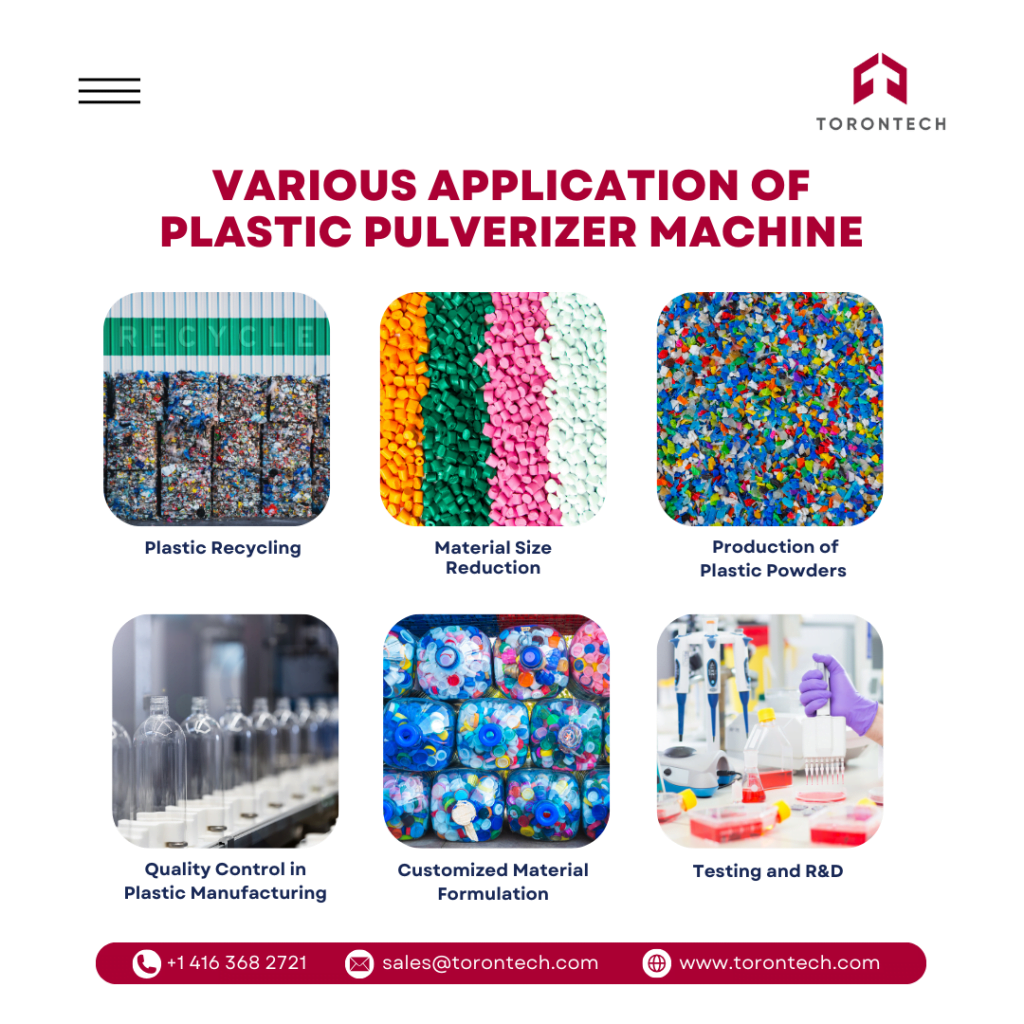

A Plastic Pulverizing Machine is a specialized equipment designed for the pulverization or grinding of plastic materials into fine particles or powder form. Here are some of the primary uses and applications of Plastic Pulverizer Machines.

1. Plastic Recycling

One of the primary purposes of a plastic pulverizer machine is to facilitate plastic recycling. It helps in the efficient processing of plastic waste, such as plastic bottles, containers, films, or other plastic products, into reusable or recyclable materials.

2. Material Size Reduction

Plastic Recycling Pulverizer Machines are employed to reduce the size of plastic materials, making them easier to handle and process. This size reduction process enhances material flow, facilitates mixing, and prepares plastic materials for further processing or manufacturing.

3. Production of Plastic Powders

Plastic Pulverizer Machines are capable of producing plastic powders of controlled particle sizes. These powders can be utilized as raw materials in various industries, including plastics manufacturing, chemical processing, and additive manufacturing (3D printing).

4. Quality Control in Plastic Manufacturing

In plastic manufacturing processes, this machine play a vital role in ensuring the uniformity and consistency of plastic materials. By pulverizing raw plastic materials, manufacturers can achieve precise particle size distribution, leading to improved product quality and performance.

5. Customized Material Formulation

Plastic Pulverizer Machines enable manufacturers to customize plastic material formulations by blending different types of plastics or incorporating additives. This flexibility allows for the creation of tailored material compositions with specific properties and characteristics to meet the requirements of diverse applications.

6. Testing and R&D

Plastic Pulverizer Machines are utilized in research and development laboratories for testing and experimentation purposes. Researchers and engineers use these machines to study the behavior of plastic materials under various processing conditions and to develop new formulations or processing techniques. If you need explore other plastic testing equipment, you can visit here.

Pulverizer machines for plastic are versatile and indispensable tools in the plastic industry, serving multiple purposes such as recycling, material size reduction, powder production, quality control, customized material formulation, and research and development.

Benefits of Effective Plastic Recycling by Using Plastic Pulverizer Machine

Plastic recycling is not just a responsible environmental practice; it offers numerous benefits that extend beyond waste reduction. When plastic waste is effectively recycled, it brings about positive impacts on various aspects of our society and the environment. Let’s explore the key benefits of effective plastic recycling by using a Plastic Pulverizer Machine.

1. Waste Reduction

Plastic waste poses a significant challenge worldwide, with vast amounts ending up in landfills or polluting our oceans and ecosystems. Effective plastic recycling diverts plastic waste from these disposal sites, minimizing the environmental impact. By reducing plastic waste, we can alleviate the strain on waste management systems and protect our natural habitats.

2. Economic Opportunities

Plastic recycling offers economic benefits by creating employment opportunities and fostering the growth of recycling industries. Recycling facilities require skilled workers for sorting, processing, and managing the recycling operations. Additionally, recycled plastics can serve as raw materials for manufacturing industries, contributing to the development of a circular economy and reducing dependence on costly virgin materials.

3. Resource Conservation

Effective plastic recycling helps conserve valuable natural resources. By recycling plastic waste, we reduce the need for virgin plastic production, which requires the extraction of fossil fuels and the consumption of energy and water resources. Recycling plastics conserves these resources for future generations while reducing the strain on the environment.

4. Energy Savings

Recycling plastic consumes significantly less energy compared to producing plastic from raw materials. The process of extracting, refining, and manufacturing virgin plastic demands substantial energy inputs.

In contrast, recycling plastic waste requires less energy, as the materials have already undergone initial processing. By recycling, we conserve energy resources and reduce greenhouse gas emissions associated with plastic production.

5. Reduced Carbon Footprint

Effective plastic recycling plays a crucial role in mitigating climate change. As mentioned earlier, recycling plastic consumes less energy compared to producing plastics from scratch. By reducing energy consumption, recycling helps decrease greenhouse gas emissions, including carbon dioxide, methane, and nitrous oxide. This reduction in carbon footprint contributes to global efforts to combat climate change.

6. Environmental Preservation

Plastic pollution has severe consequences for our environment and ecosystems. By recycling plastic waste effectively, we can mitigate these impacts. Recycling reduces the need for incineration, which releases harmful pollutants into the air. It also prevents plastic waste from entering water bodies, protecting marine life and preserving delicate ecosystems.

7. Sustainable Material Use

Effective plastic recycling promotes the concept of a circular economy, where materials are reused and recycled rather than disposed of. By recycling plastics, we extend the lifespan of these materials, reducing the demand for new plastic production. This shift towards sustainable material use helps create a more resilient and resource-efficient society.

Effective plastic recycling brings about a multitude of benefits, ranging from resource conservation and energy savings to waste reduction and economic opportunities. By embracing Plastic Pulverizer Machines for plastic recycling practices, you can contribute to a cleaner environment, reduce our carbon footprint, and pave the way for a more sustainable future.

Factors to Consider When Choosing a Plastic Pulverizer Machine

Selecting the right plastic pulverizer machine is vital for achieving optimal results in plastic recycling operations. With numerous options available in the market, it is essential to consider several factors to ensure that the chosen machine meets specific requirements and delivers efficient performance. Here are the key factors to consider when choosing a plastic pulverizer machine manufacturer.

1. Type of Plastic Waste

Different plastic pulverizer machines are designed to handle specific types of plastic waste. Consider the composition and characteristics of the plastic materials you intend to process. Some machines are more suitable for rigid plastics like bottles and containers, while others excel at grinding flexible films or sheets. Ensure that the machine is compatible with the type of plastic waste you will be recycling.

2. Required Output and Throughput

Determine the desired output capacity and throughput of the plastic pulverizer machine. These specifications depend on the scale of your recycling operation and the volume of plastic waste you need to process. Consider factors such as the machine’s motor power, grinding speed, and capacity to ensure it can meet your production requirements effectively.

3. Particle Size Control

The ability to control the particle size of the pulverized plastic is crucial for various recycling applications. Determine the desired particle size range you need for your specific recycling processes. Some machines offer adjustable screens or sieves to control the final particle size. Ensure that the chosen machine can achieve the desired particle size distribution to meet your recycling goals.

4. Cost and Return on Investment (ROI)

Assess the plastic pulverizer machine cost and evaluate the potential return on investment. Consider not only the initial purchase cost but also long-term operating costs, including energy consumption and maintenance requirements. A higher-priced machine with better efficiency and durability may provide greater ROI in the long run.

5. Machine Configuration and Design

Evaluate the machine’s configuration and design to ensure it aligns with your operational needs. Consider factors such as the machine’s footprint, ease of installation, maintenance requirements, and safety features. A well-designed machine with user-friendly controls and accessible components can streamline operations and enhance overall efficiency.

6. Energy Efficiency

Energy efficiency is an important consideration to minimize operational costs and environmental impact. Look for plastic pulverizer machines that are designed with energy-saving features, such as efficient motors and optimized grinding mechanisms. Energy-efficient machines can significantly reduce power consumption while maintaining high productivity.

7. Durability and Maintenance

Consider the machine’s build quality, durability, and maintenance requirements. Look for robust construction, high-quality materials, and reliable components that can withstand the demands of continuous operation. Additionally, assess the ease of maintenance, availability of spare parts, and accessibility for cleaning and maintenance tasks.

8. Reputation and Supplier Support

Research the reputation and track record of the machine manufacturer or supplier. Look for reputable companies with a history of producing reliable and high-performance plastic pulverizer machines. Additionally, consider the level of technical support, after-sales service, and availability of spare parts provided by the supplier.

If you are confused about finding the right Plastic Pulverizing Machine suppliers, you can consider Torontech. We offer an extensive range of Plastic Pulverizing Machines with cost-effective solutions. Please contact us today. Our team is always ready to assist you and guide you in finding the right product.

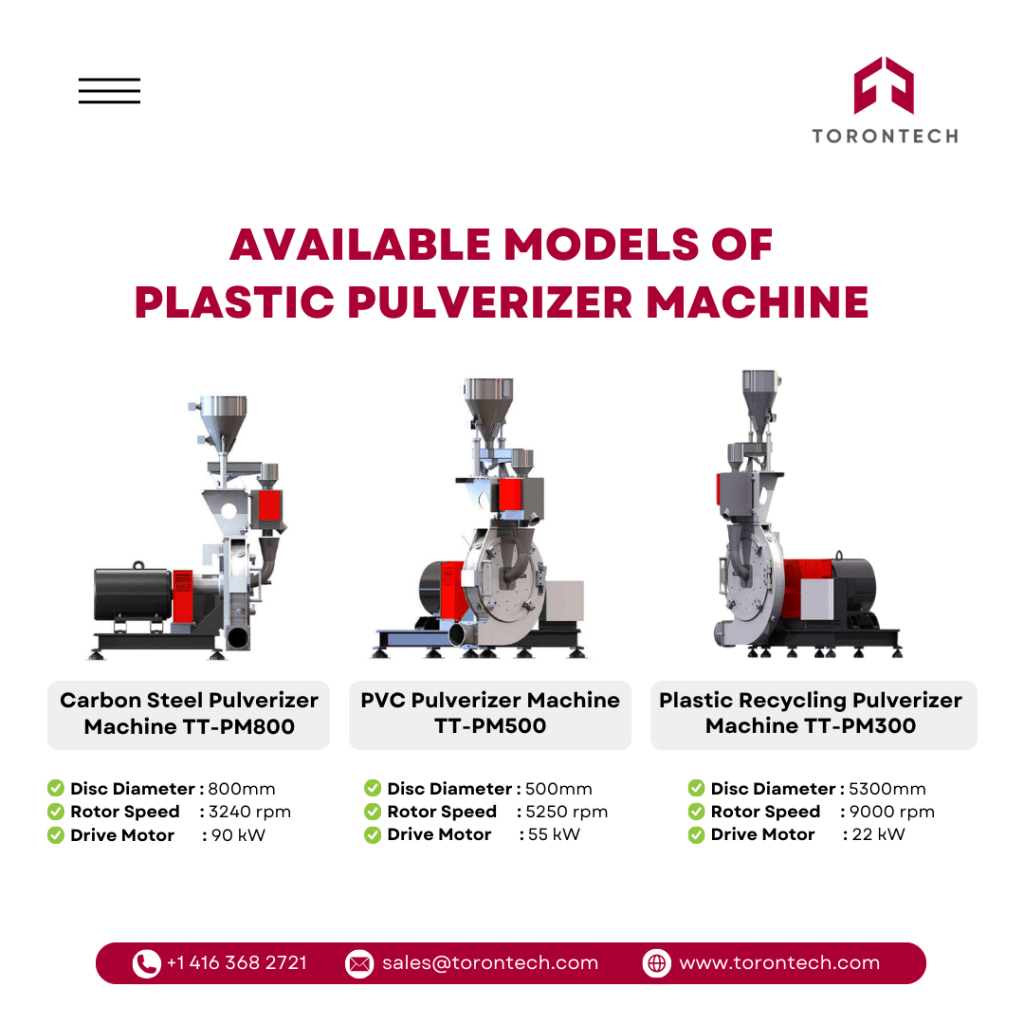

Available Models of Torontech’s Plastic Pulverizer Machine

Torontech offers a range of advanced Plastic Pulverizer Machines tailored to various recycling needs, including the Carbon Steel Pulverizer Machine TT-PM800, PVC Pulverizer Machine TT-PM500, and Plastic Recycling Pulverizer Machine TT-PM300. Let’s delve into the unique features, applications, and technical specifications of each model.

A. Carbon Steel Pulverizer Machine TT-PM800

The TT-PM800 is designed for crushing semi-rigid, brittle, and impact-resistant materials, transforming them into powdered products. With a particle size ranging from 300 to 1000 microns, it’s suitable for processing LDPE, HDPE, UPVC, PC, and other plastics. Notable features include extended disc lifespan, adjustable final size, and efficient operation.

B. PVC Pulverizer Machine TT-PM500

Ideal for processing semi-rigid, brittle, and impact-resistant materials, the TT-PM500 creates powdered products within the 300-1000 micron range. Commonly used for shredding LDPE, HDPE, UPVC, PC, and other plastics, it offers advantages such as extended disc lifespan, quick disc replacement, and high throughput capacity.

C. Plastic Recycling Pulverizer Machine TT-PM300

The TT-PM300 series is tailored for pulverizing materials into powdered products within the 300-1000 micron range. Suitable for LDPE, HDPE, UPVC, PC, and other plastics, it features extended disc lifespan, adjustable final size, and high throughput capacity. This model is designed for efficient and cost-effective operation.

To help you compare the technical specifications of every model, you can refer to the table below.

|

Specification |

Carbon Steel TT-PM800 | PVC TT-PM500 | Plastic Recycling TT-PM300 |

|

Raw Material |

H-PVC-Profile, H-PVC-Pine, LDPE(MFI70), etc. |

||

|

Storage Container Capacity |

50 – 100 liters |

||

|

Rotor Speed |

3240 rpm | 5250 rpm |

9000 rpm |

|

Disc Diameter |

800mm | 500mm |

300mm |

|

Drive Motor |

90 kW | 55 kW |

22 kW |

|

Final Product & Capacity |

400~1000kg/h, depending on the condition of the client’s material. |

250~500kg/h, depending on the condition of the client’s material. |

120~200kg/h, depending on the condition of the client’s material. |

| Voltage |

3×380V, 50Hz; control current 220V, 50Hz (110V is also available. Please specify when ordering) |

||

This table concisely compares the technical specifications for each type of Torontech Plastic Pulverizer Machine, allowing for easy evaluation and selection based on specific requirements.

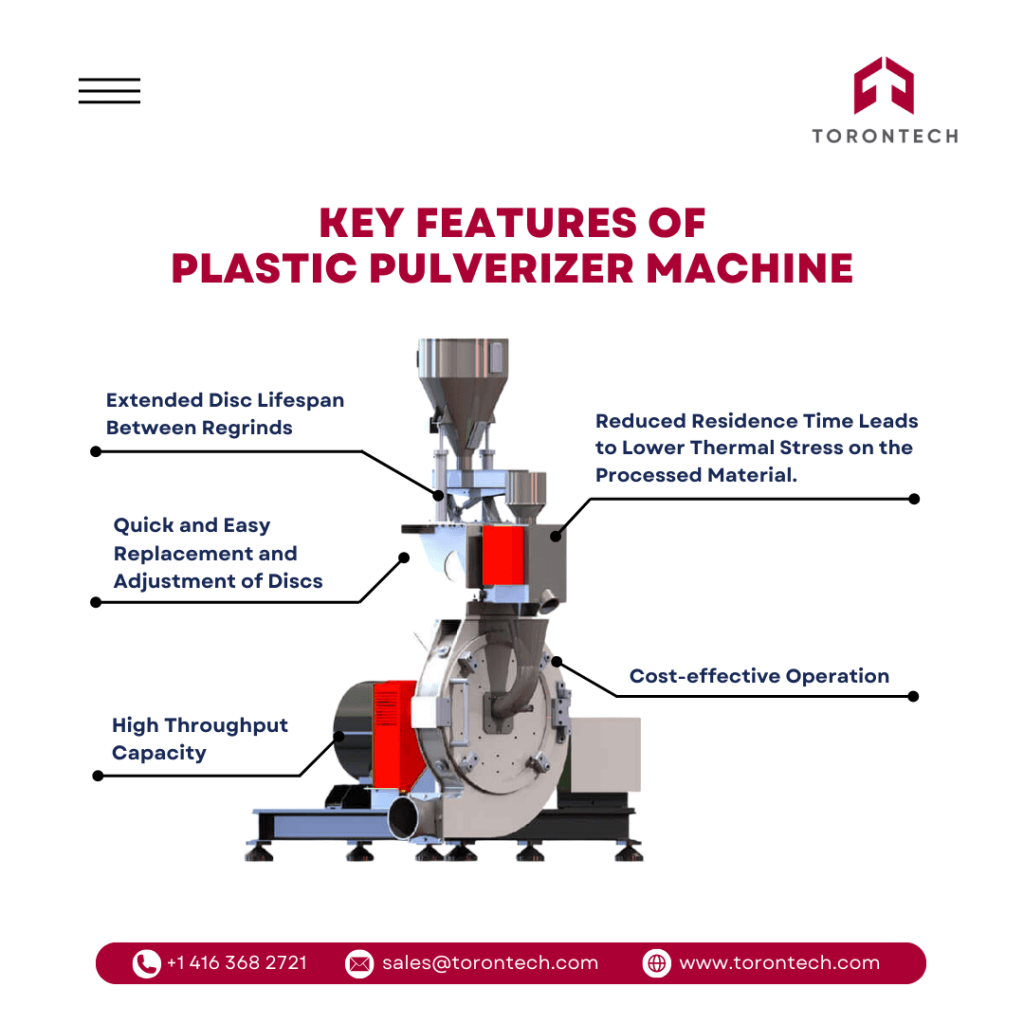

All our types of Plastic Pulverizer Machine have advantages such as

- Extended disc lifespan between regrinds.

- Quick and easy replacement and adjustment of discs.

- Reduced residence time leads to lower thermal stress on the processed material.

- High throughput capacity.

- Cost-effective operation.

By understanding the capabilities and specifications of each type, you can choose the one that best fits your plastic recycling needs. Maybe you’re wondering, what is the price of a Plastic Pulverizer Machine?

The price of the Plastic Pulverizer Machine may vary depending on the customer’s capacity requirements and the optional machines chosen. Please reach out to us for a price quotation. Do not hesitate to contact us regarding this Plastic Pulverizer Machine at your convenience. We are here to assist you.

Conclusion and Additional Information

Plastic Pulverizer Machines have emerged as indispensable tools in plastic recycling. With their ability to efficiently process and transform plastic waste into reusable materials, these machines contribute to waste reduction, resource conservation, and the development of a circular economy.

Torontech’s range of Plastic Pulverizer Machines offers advanced solutions for Plastic Recycling needs. Whether you’re processing semi-rigid, brittle, or impact-resistant materials, our machines deliver efficient performance and high-quality results.

With options like the Carbon Steel TT-PM800, PVC TT-PM500, and Plastic Recycling TT-PM300, we cater to diverse requirements and applications. From adjustable particle sizes to high-speed operation, each machine is designed for reliability and productivity.

To learn more about our range of Plastic Recycling and explore every Plastic Pulverizer Machine’s technical specifications in detail, visit our website today. Don’t hesitate to contact us if you have any further questions or need assistance in choosing the right machine for your recycling operations.