JAW CRUSHERS

Torontech Jaw Crushers are built for fast, precise crushing of hard and brittle materials. From compact bench-top designs to high-capacity models, they offer excellent sample fineness, durable construction, and user-friendly features. Ideal for labs and small-scale production.

Available Products | Jaw Crushers for Sale

Jaw Crusher JC7

| Feed size:<110mm

| Final fineness: 95%<2mm

| Speed: 740rpm

Jaw Crusher JC6

| Feed size: <40mm

| Final fineness: <0.5mm

| Speed: 500-1000rpm

Jaw Crusher JC5

| Feed size:<90mm

| Final fineness:<2mm

| Speed:305rpm

Applications Across Industries

Our jaw crushers are suitable for various materials, including:

Mining & Metallurgy: ores, coal, slag, coke, niobium, titanium alloys, vanadium iron, chrome vanadium, tungsten carbide

Chemical Industry: pre-treatment of chemical raw materials for further analysis

Geology & Mineralogy: rocks, granite, basalt, barite, silicates

Ceramics: talc, sintered clay, electric ceramics

Construction Materials: bauxite, quartz, cement, slag bricks

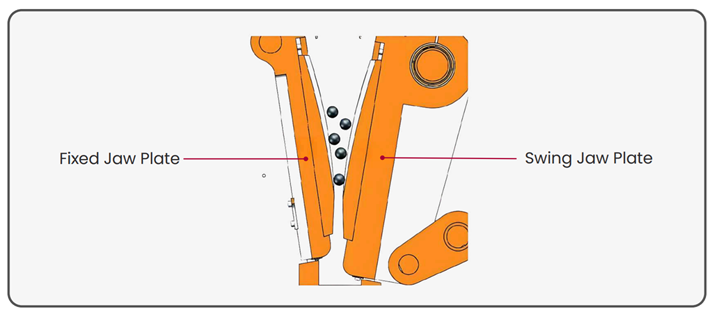

Working Principle of Jaw Crushers

All Torontech jaw crushers operate based on a wedge-shaped crushing chamber. Samples are fed through an anti-splash hopper into the chamber. One jaw remains fixed, while the other is driven by a curved axle, moving in an elliptical pattern powered by a continuously rotating motor.

This motion creates a strong squeezing force, reducing sample size efficiently. Once the material reaches a size smaller than the discharge gap, it falls into a secure collection drawer.

This design ensures:

Consistent size reduction

Gravity-assisted discharge

Minimal sample contamination

Easy cleanup and operation

Frequently Asked Questions (FAQ) – Jaw Crushers

What is a Jaw Crusher?

A jaw crusher is a mechanical device used for crushing hard, brittle, and tough materials. It operates by compressing material between a fixed jaw and a moving jaw, forming a V-shaped chamber. As the moving jaw exerts force on the material, it breaks into smaller pieces, which then fall through the discharge opening.

What is a jaw crusher used for?

A jaw crusher is used for the primary size reduction of hard, brittle, and tough materials. It is commonly used in laboratories, mining, metallurgy, geology, ceramics, chemicals, and construction industries. Jaw crushers break down large samples into smaller pieces for further analysis or processing.

What are the advantages of a jaw crusher?

High crushing efficiency

Wide material compatibility (ores, ceramics, slag, coal, etc.)

Simple structure with easy maintenance

Available in both desktop and floor-standing models

Adjustable gap for precise final fineness

Multiple jaw plate material options to reduce contamination

What are the disadvantages of a jaw crusher?

Not suitable for very soft or sticky materials

Produces more dust compared to other crushers

Final particle size may require secondary milling

Larger models require more space and installation setup

How do I select the right jaw crusher model?

Choose based on:

Feed size and final fineness requirements

Sample type (hardness, abrasiveness)

Throughput capacity

Space constraints (desktop vs. floor models)

Contamination concerns (jaw plate material options)

Please Contact us for pricing, check availability, or ask for additional information about our Jaw Crushers